Noise reduction device and gas water heater

A technology of noise reduction and inner peripheral wall, which is applied in the field of noise reduction and noise reduction, and can solve problems such as poor noise reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

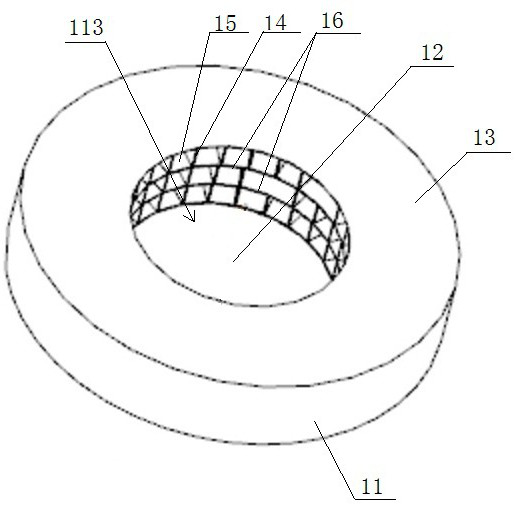

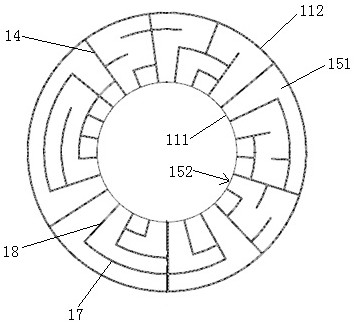

[0026] Embodiment 1, this embodiment proposes a noise reduction device, such as figure 1 , figure 2 As shown, it includes a barrel-shaped body with an open end connected by a peripheral wall 11 and a bottom wall 12. The peripheral wall 11 includes an inner peripheral wall 111 and an outer peripheral wall 112. There is a gap between the walls 112. One end of the inner peripheral wall 111 and the outer peripheral wall 112 is sealed with the bottom wall 12, and the other end is connected by the connecting panel 13. The bottom wall 12, the inner peripheral wall 111, the outer peripheral wall 112 and the connecting panel 13 are enclosed by A closed cavity, the cavity is partitioned by the first partition 14 to form a number of muffler cavities 15, and at least one second partition 16 is arranged in the muffler cavity 15, and the muffler cavity 15 is partitioned by the second partition 16 to form several layers of sub-mufflers The cavity 151 and the sub-muffler cavity 151 are inde...

Embodiment 2

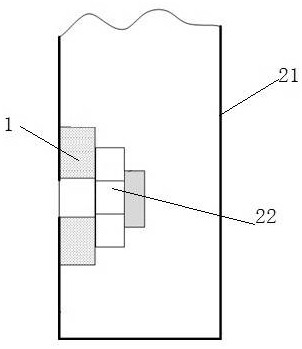

[0040] Embodiment 2, this embodiment proposes a gas water heater, such as Figure 4-Figure 7 As shown, it includes a casing 21 and a fan 22 arranged in the casing 21. The casing 21 is provided with an air inlet 23 opposite to the inlet of the fan 22, and the top of the casing 21 is provided with a smoke pipe 24 passing through. Hole 25, the noise reduction device 1 is arranged in the housing 21, such as figure 1 As shown, it includes a barrel-shaped body with an open end connected by a peripheral wall 11 and a bottom wall 12. The peripheral wall 11 includes an inner peripheral wall 111 and an outer peripheral wall 112. There is a gap between the walls 112. One end of the inner peripheral wall 111 and the outer peripheral wall 112 is sealed with the bottom wall 12, and the other end is connected by the connecting panel 13. The bottom wall 12, the inner peripheral wall 111, the outer peripheral wall 112 and the connecting panel 13 are enclosed by A closed cavity, the cavity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com