Storage reliability evaluation method of single relay based on process and reliability block diagram

A relay and reliability technology, which is applied in the field of performance analysis of relay-type stand-alone products, can solve the problems of inability to accurately evaluate the storage reliability of relay-type stand-alone machines, unable to accurately reflect the dispersion characteristics of relay-type stand-alone machines, etc., so as to improve the storage reliability evaluation accuracy, Solve the effect of low accuracy of storage reliability assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

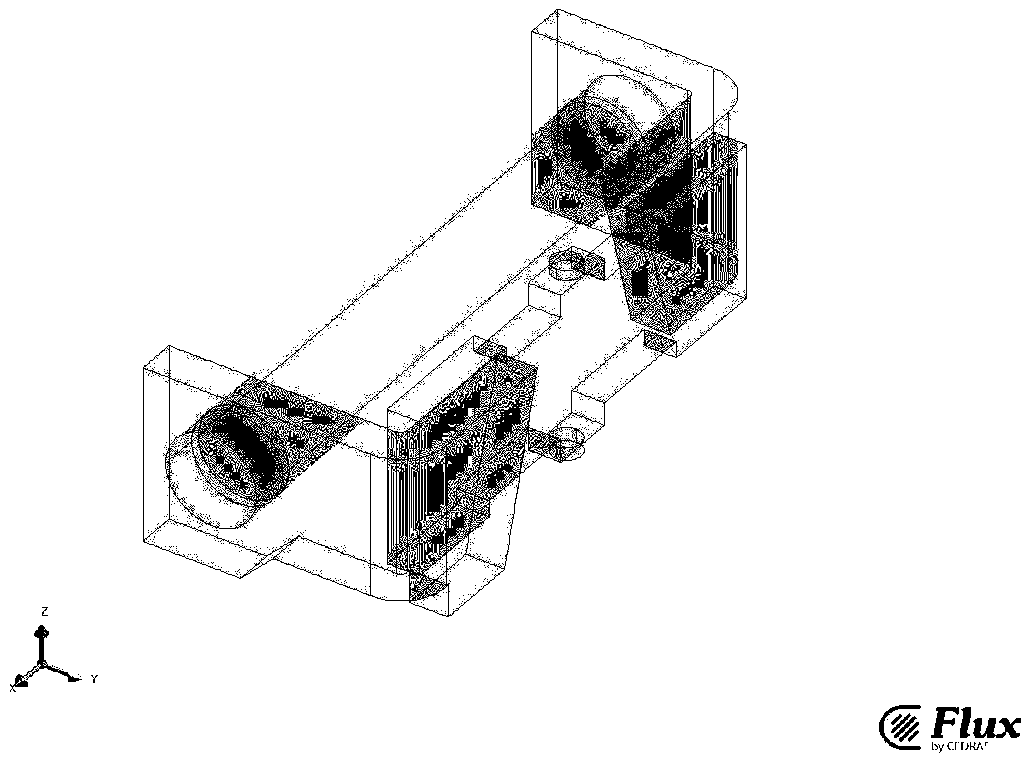

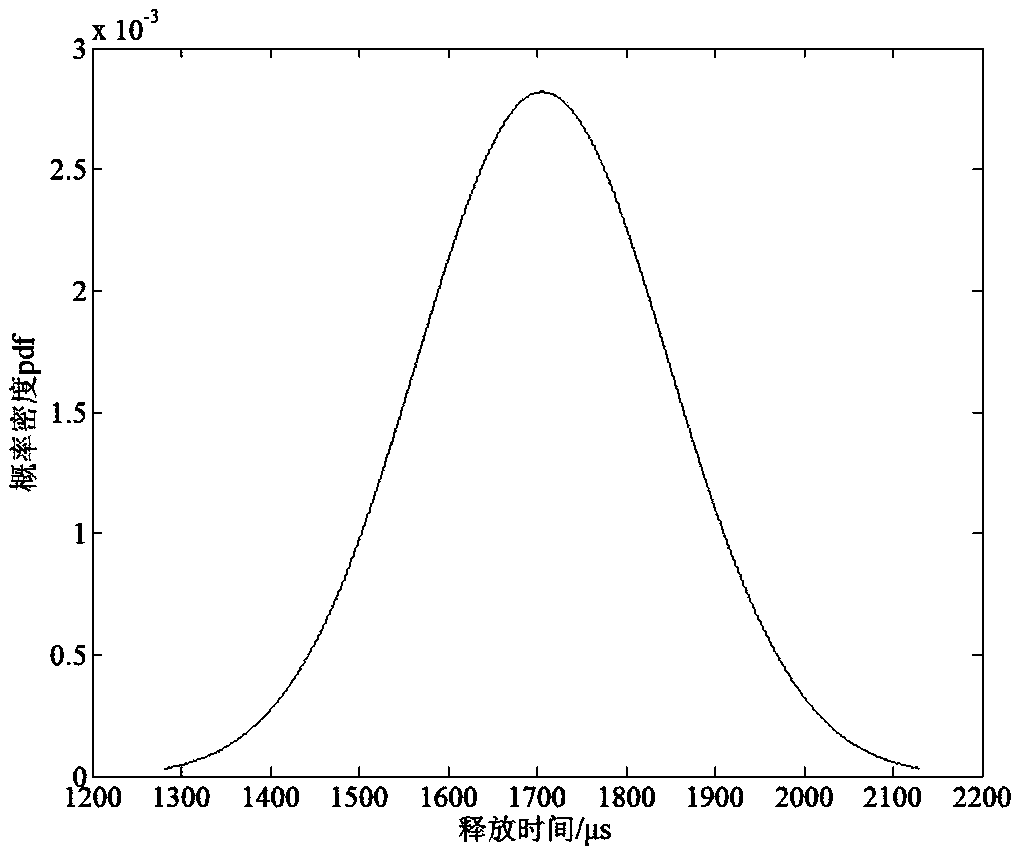

[0027] Specific implementation mode 1: This implementation mode provides a method for evaluating the storage reliability of a relay-type stand-alone unit combined with a process and a reliability block diagram. First, the process data investigated by the manufacturer is injected into the established relay finite element simulation model, and the obtained The initial distribution characteristics of its output characteristics; then, by analyzing the actual failure mode and failure mechanism of the relay single machine, a degradation model based on failure physics is established, combined with the initial distribution characteristics of the relay and the measured data of the accelerated storage degradation test, the relay with distribution characteristics is obtained Output characteristic degradation model; finally, the failure threshold is brought into the relay output characteristic degradation model to obtain the relay storage reliability data, and bring it into the established ...

specific Embodiment approach 2

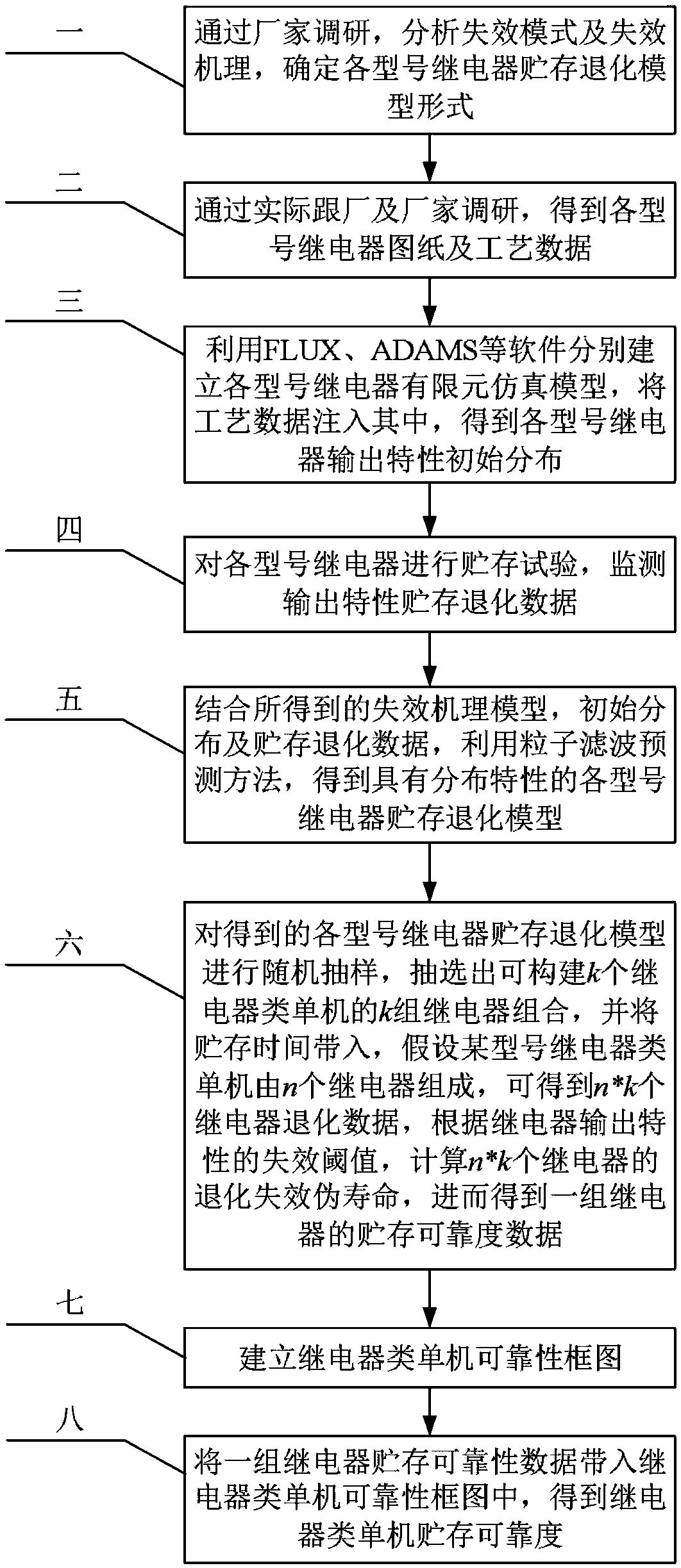

[0037] Specific implementation mode two: In this implementation mode, a certain type of relay class stand-alone is used as an object to carry out storage reliability evaluation combined with process and reliability block diagram, such as figure 1 As shown, the specific steps are as follows:

[0038] Step 1: According to the survey results and functional analysis of the manufacturer, the failure mode of a certain type of relay is mainly due to the out-of-tolerance time. Since the relay type stand-alone is mainly composed of various types of relays, its disconnection time is directly determined by the release time of each type of relay, and the release time is determined by the reaction force of the relay. The reaction force of the relay is provided by the reed. As an elastic element, the reed will experience stress relaxation during storage, and the reaction force provided by the reed will decrease, which will lead to an increase in the release time of the relay. In the study of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com