Mobile phone case with anti-fall protection function and manufacturing method thereof

A technology of protection function and production method, which is applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problem that anti-seismic performance cannot meet the requirements of anti-slip, convenience and aesthetics, single function, anti-seismic and drop-proof performance can not meet the expected requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

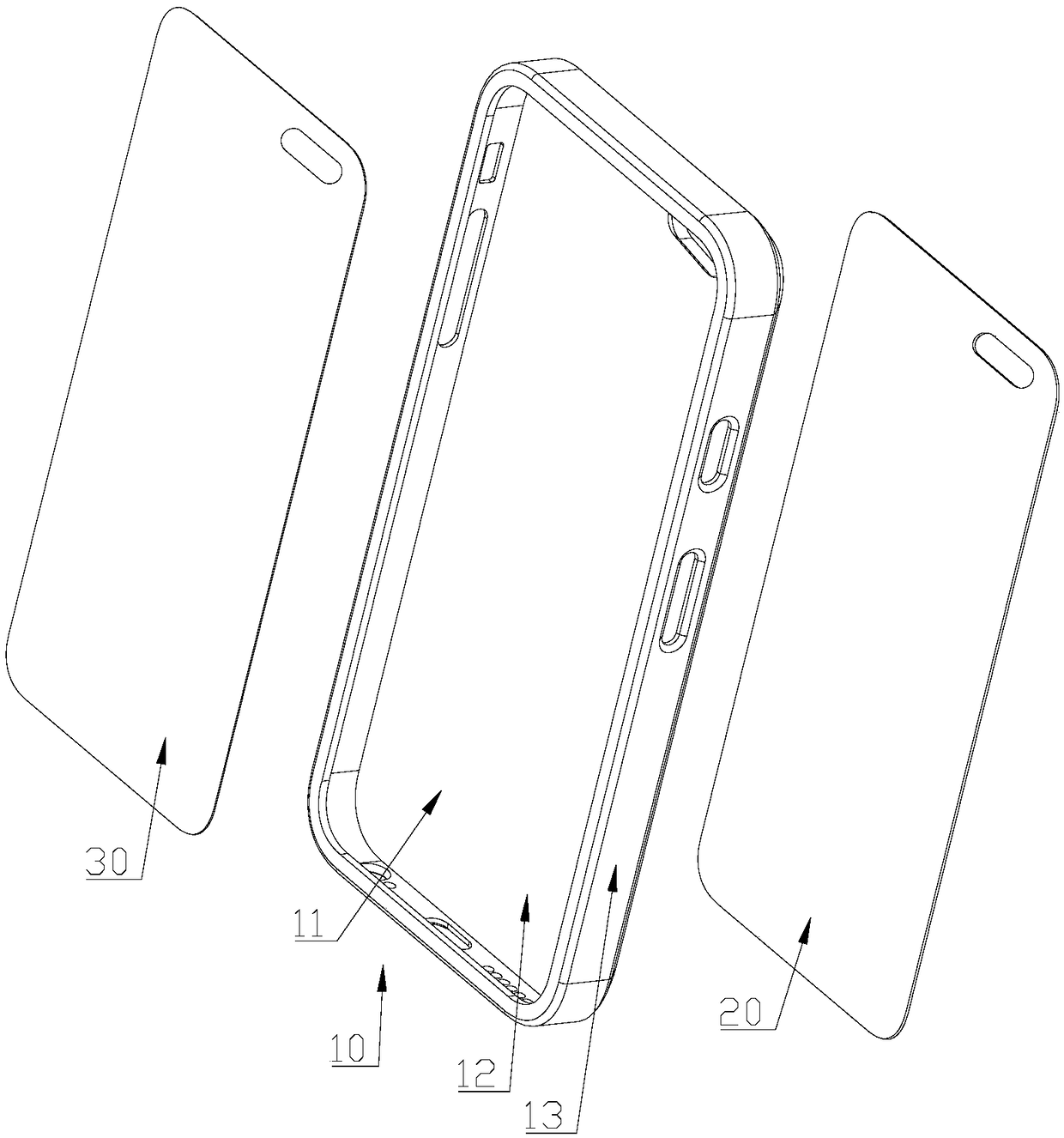

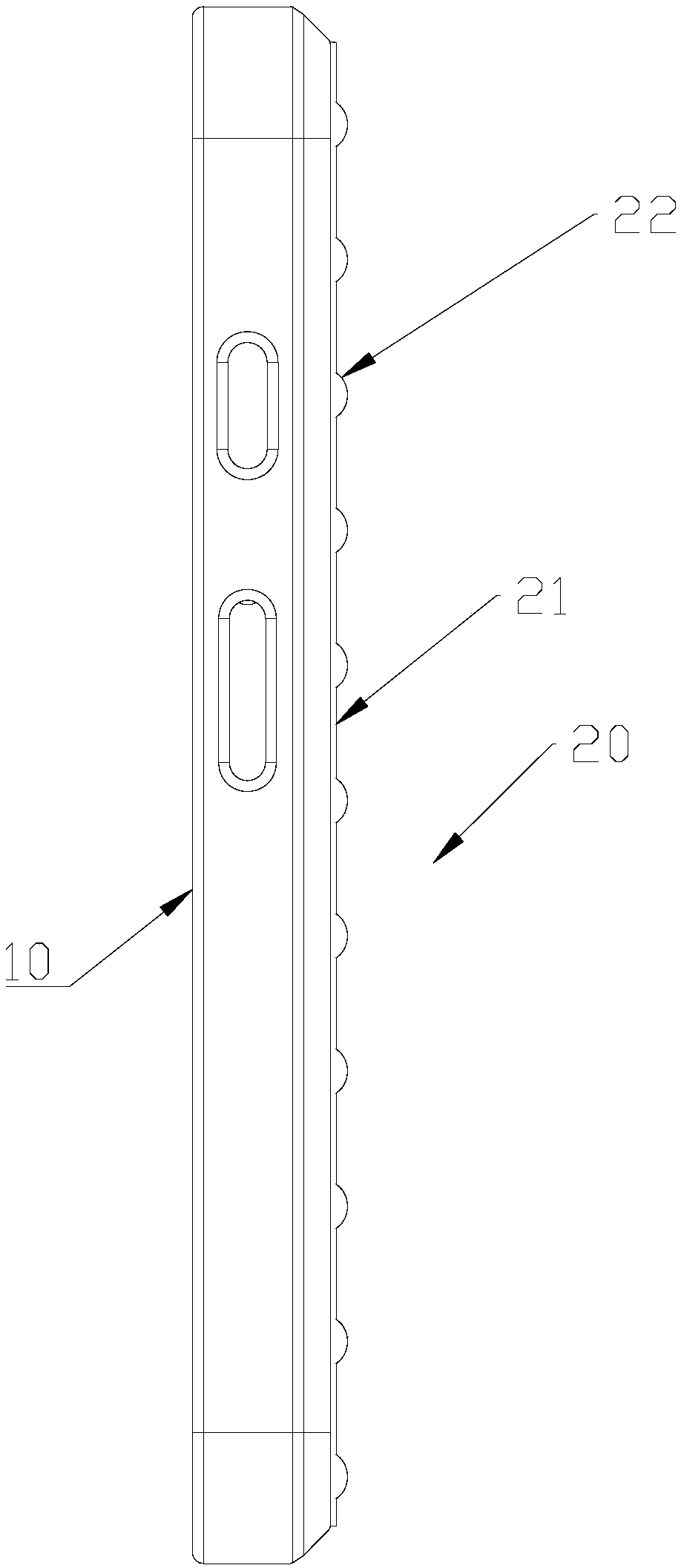

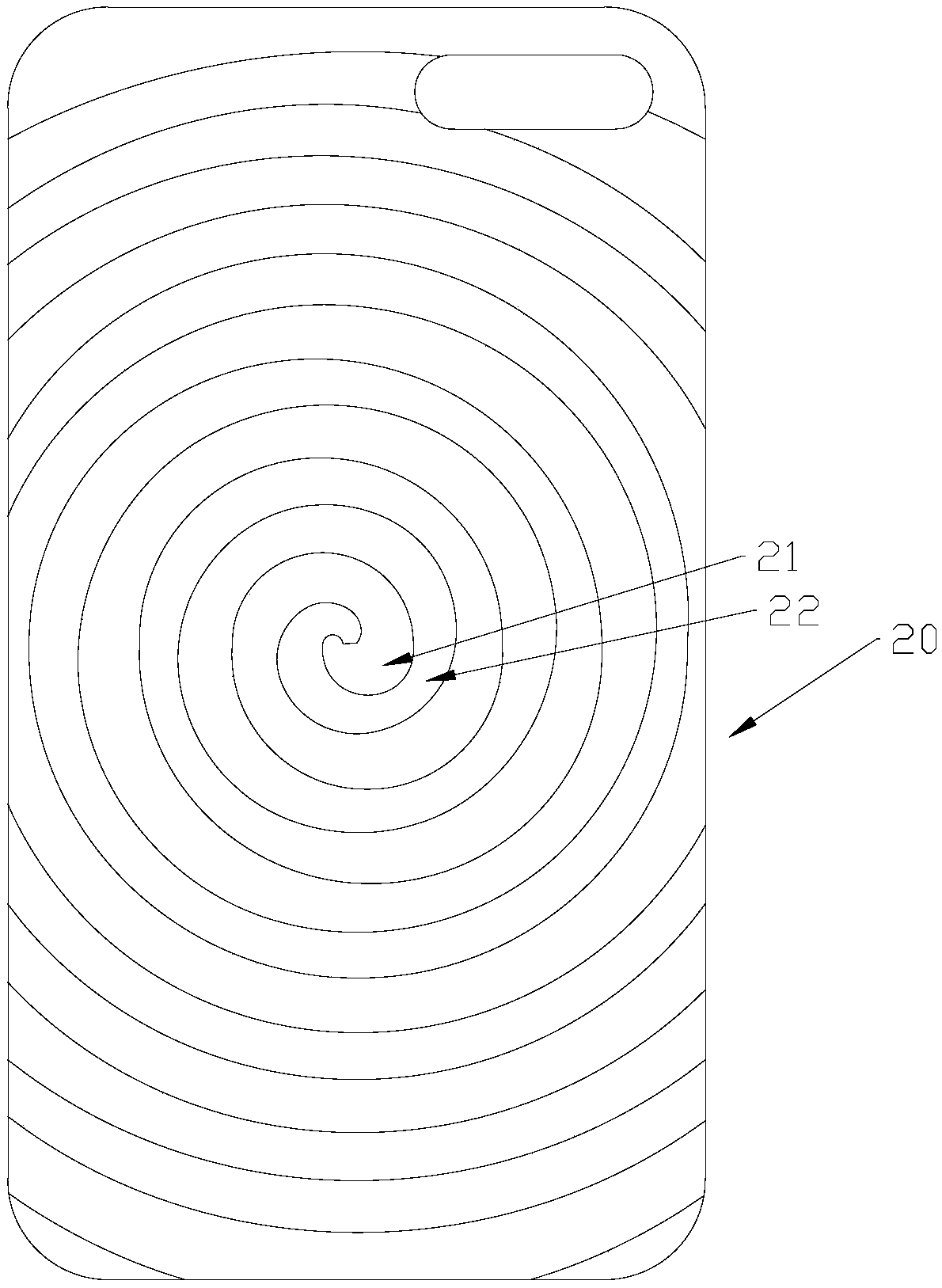

[0039] This embodiment introduces the mobile phone case with anti-fall protection function of the present invention, which includes a main body 10 of the mobile phone case and a protective layer 20 . In addition, it may also include a fleece layer 30 .

[0040] The mobile phone case main body 10 is used to be set outside the mobile phone, and its shape and size can be set according to the shape and size of the mobile phone. The mobile phone case main body 10 includes a planar back panel 12 and an enclosing section 13 enclosing the edge of the back panel 12 , the accommodating cavity is formed between the enclosing section 13 and the back panel 12 11. The accommodating cavity 11 is used for accommodating a mobile phone. In addition, corresponding holes are provided on the enclosure portion 13 and the back panel portion 12, so as not to interfere with or affect the function of each component of the mobile phone. For example, several button holes, A camera hole is provided on t...

Embodiment 2

[0050] This embodiment provides a method for manufacturing a mobile phone case with anti-drop protection function. The method includes the following steps:

[0051] S1, process the main body of the mobile phone case; in this step, the main body of the mobile phone case can be processed by plastic injection molding process, and its specific process conditions and process steps can refer to the known technology, such as the hard shell mobile phone in the prior art Shell processing technology, etc. In this embodiment, the main body of the mobile phone case is injection molded from TPU+ABS material.

[0052] S2. Process the protective layer through a hot pressing forming process, so that one side surface of the protective layer is flat, and one side surface is provided with the protrusions and depressions to be uneven; specifically, it includes the following steps: Select a 2mm thick EVA foam sheet, or use the existing EVA foam material to cut it into a 2mm thick EVA foam sheet;...

Embodiment 3

[0055] This embodiment provides a method for manufacturing a mobile phone case with anti-drop protection function. The method includes the following steps:

[0056] S1, process the main body of the mobile phone case; in this step, the main body of the mobile phone case can be processed by plastic injection molding process, and its specific process conditions and process steps can refer to the known technology, such as the hard shell mobile phone in the prior art Shell processing technology, etc. In this embodiment, the main body of the mobile phone case is injection molded from TPU+ABS material.

[0057] S2. Process the protective layer through a hot pressing forming process, so that one side surface of the protective layer is flat, and one side surface is provided with the protrusions and depressions to be uneven; specifically, it includes the following steps: Select a 3mm thick EVA foam sheet, or use the existing EVA foam material to cut it into a 3mm thick EVA foam sheet;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com