Lifting type fire protection and fire extinguishing hood

A fire-extinguishing hood, lift-type technology, applied in fire rescue, medical science, dentistry, etc., can solve the problems of difficulty in extinguishing, fast fire spread of high-power electrical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

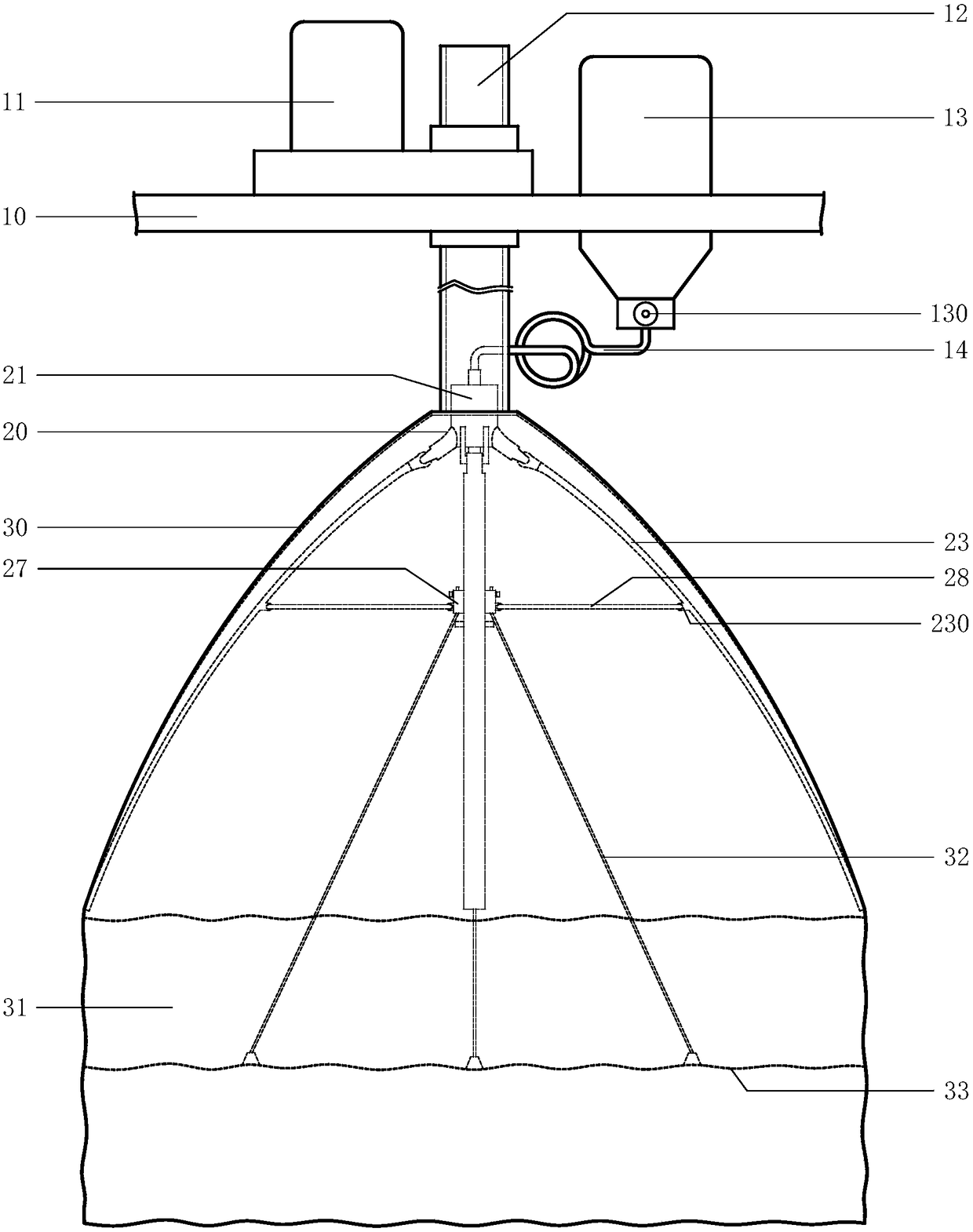

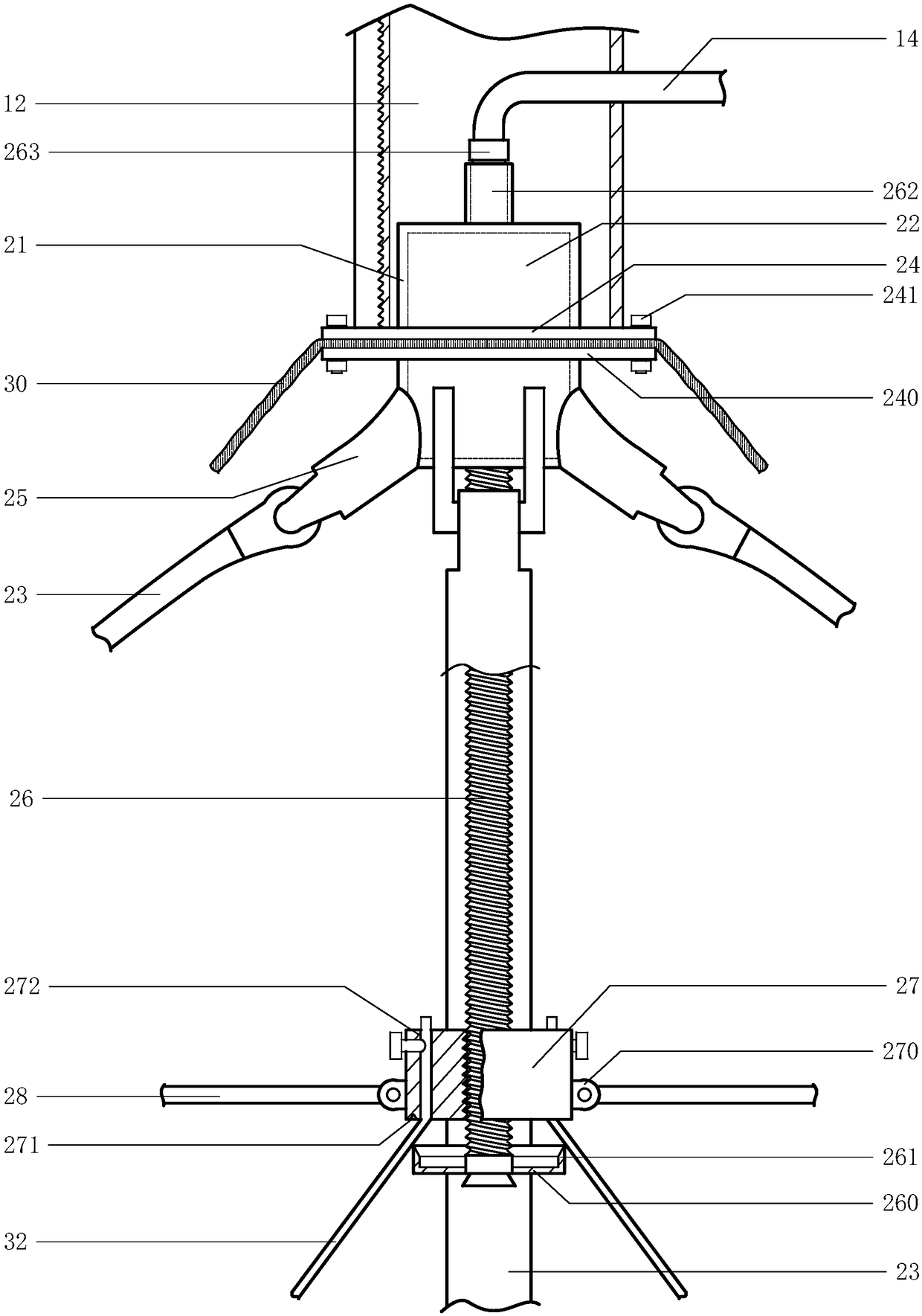

[0018] see figure 1 and combine figure 2 , the lifting type fire extinguishing hood of the present embodiment comprises an elevated platform 10, an awning opening and closing frame 20 and a fire extinguishing awning 30. 11 is provided with a tubular lifting frame 12, and the canopy opening and closing frame 20 includes a main roof frame 21, a frame body opening and closing machine 22 and multiple opening and closing struts 23, and the canopy main frame 21 is cylindrical structure and the middle part is provided with awning ribs 24, and the bottom is provided with a plurality of supporting rod shaft seats 25. The tubular lifting frame 12 is connected with the main frame 21 of the awning, and the frame tensioning machine 22 is installed on the awning. The inner cavity of the main frame 21 is provided with a rotating screw 26. The top of the rotating screw 26 penetrates upwards from the top of the roof main frame 21, and the bottom end extends downward from the bottom of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com