Double-gripper cutting machine with rolling wheels

A cutting machine and roller-type technology, applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of time-consuming and labor-intensive mobile cutting machines, easy to produce defective products, and accidents, so as to avoid accidental slipping and facilitate movement , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0010] All the features disclosed in this specification, or all disclosed methods or steps in the process, except for mutually exclusive features and / or steps, can be combined in any manner.

[0011] Any feature in this specification, unless specifically stated, can be replaced by other equivalent or equivalent alternative features. That is, unless otherwise stated, each feature is just one example of a series of equivalent or similar features.

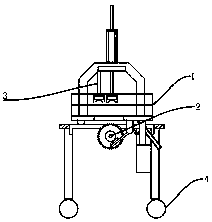

[0012] Such as figure 1 The illustrated double-handle cutting machine with rollers includes a cutting machine body 1 which includes a cutting wheel 2 and two grippers 3, and the bottom of the cutting machine body 1 is provided with rollers.

[0013] During use, when cutting operations are required, first move the cutting machine to a suitable position through the roller 4, then use the gripper 3 to control the workpiece to be processed, and then start the cutting machine to make the cutting wheel 2 start the cutting operation After the cut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap