Panel filter with molded frame and integral seal

A filter and molding technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, separation methods, etc., can solve problems such as leakage paths and filter elements that cannot be tightly matched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

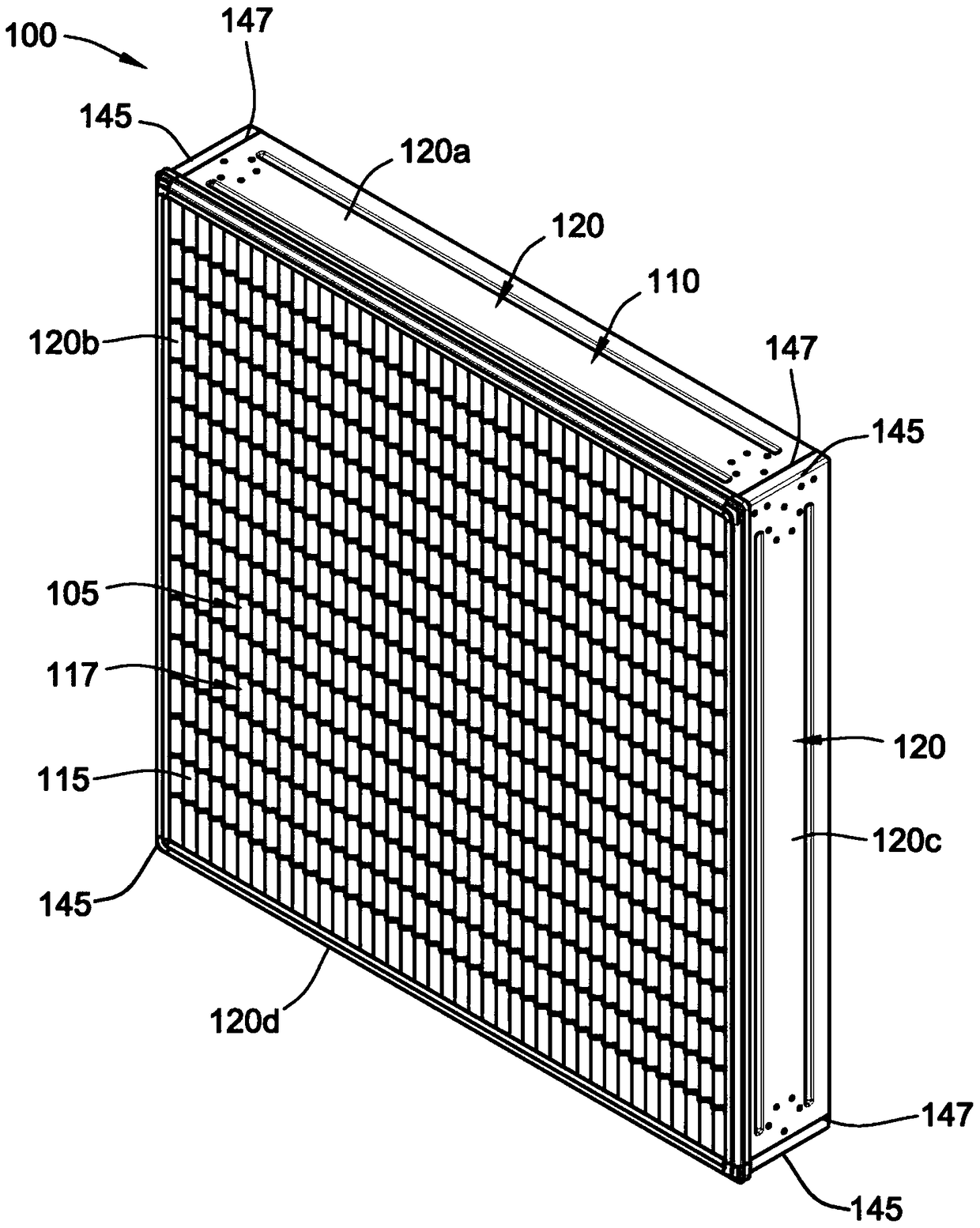

[0089] figure 1 A filter cartridge 100 is depicted according to an exemplary embodiment. The filter cartridge 100 includes a filter element 105 and a frame 110 .

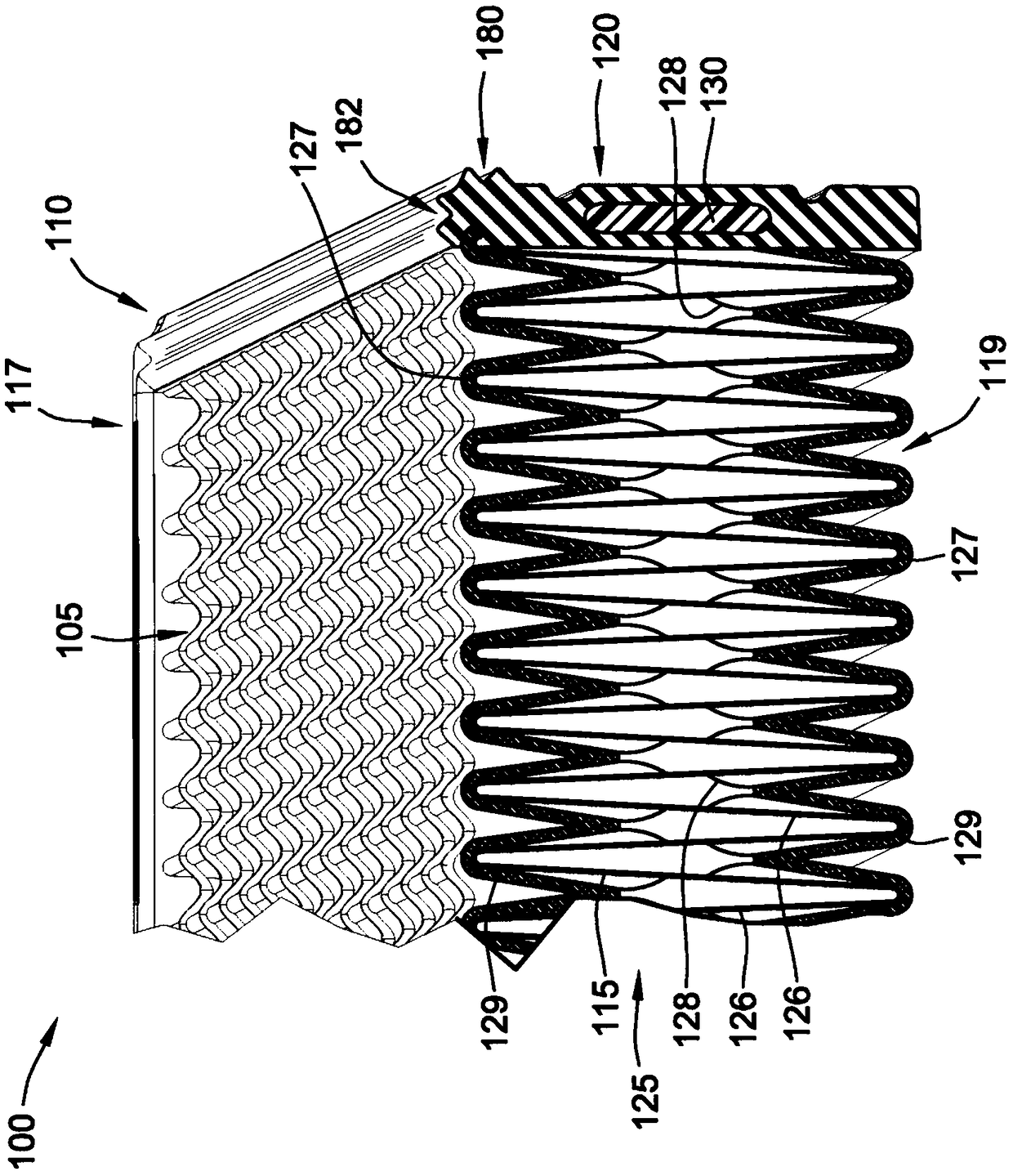

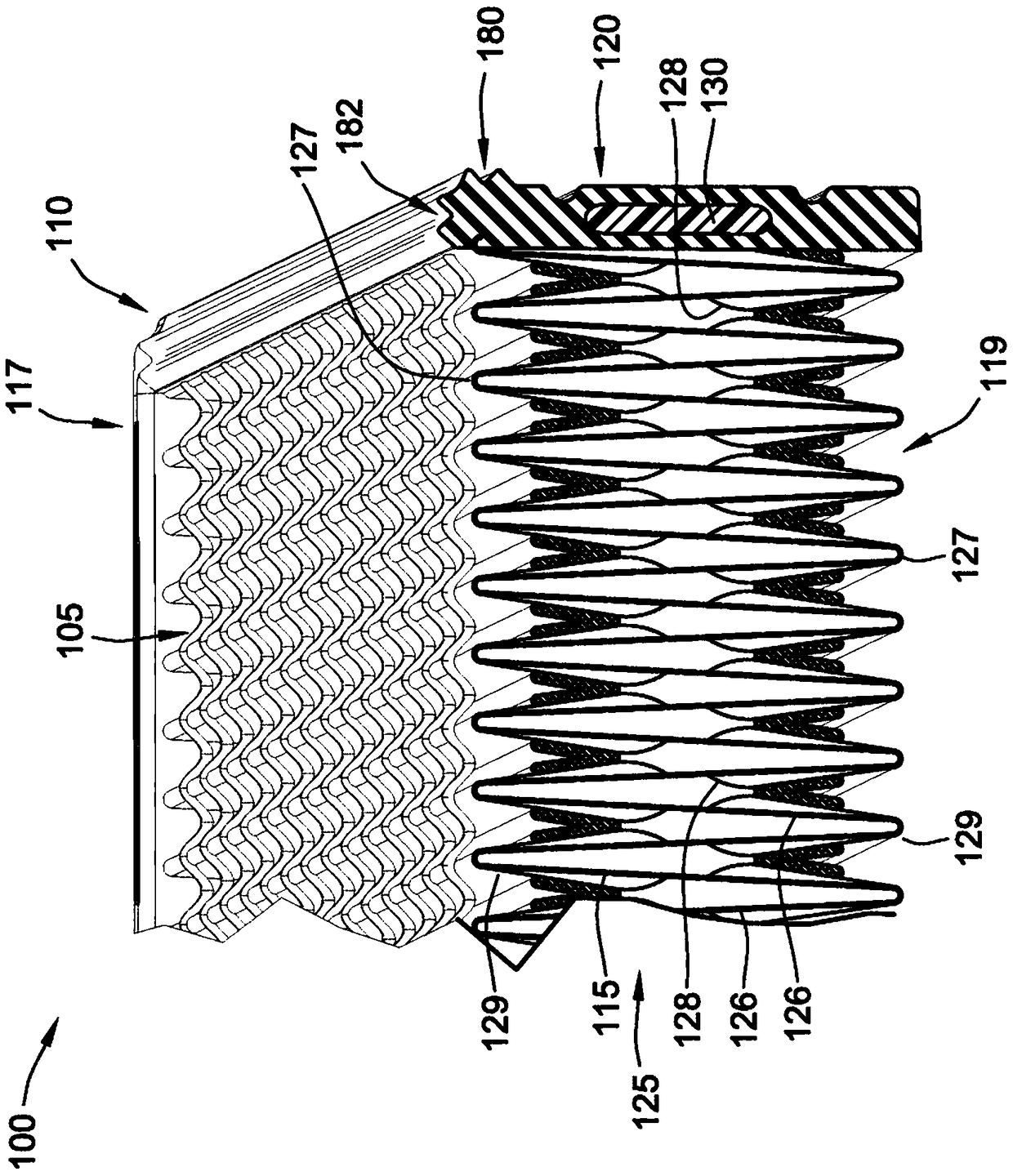

[0090] Such as Figure 2A As shown, filter element 105 includes filter media 115 extending between an outlet face 117 and an inlet face 119 . Although depicted as an outlet face 117 and an inlet face 119, those skilled in the art will recognize that the two faces are reversible, ie, unfiltered air can flow into either side so that filtered air can flow out the other. However, for purposes of reference, inlet and outlet faces are used herein to describe the various embodiments of the filter cartridges depicted in the figures. Furthermore, in a preferred embodiment, outlet face 119 has an axial seal feature (as will be discussed in more detail below) such that the force of incoming air entering filter element 105 causes the axial seal on rim 110 to press against Filter housing for enhanced sealing.

[0091] retur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com