Black coloring method for pistacia weinmannifolia

A purple oil wood, black technology, applied in chemical instruments and methods, wood treatment, wood processing appliances, etc., can solve the problems of exposed stirring blades, simple structure, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

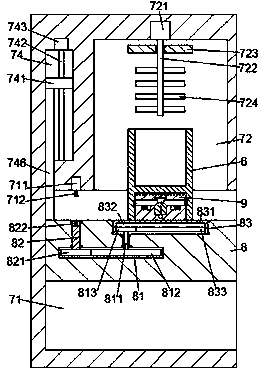

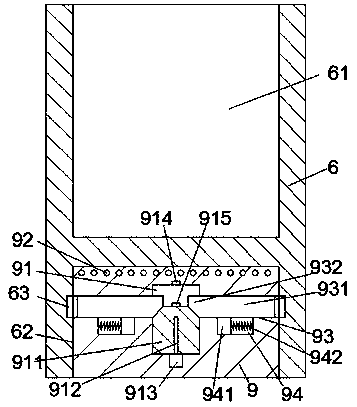

[0011] Combine below Figure 1-3 The present invention will be described in detail.

[0012] refer to Figure 1-3 , according to an embodiment of the present invention, a black-painted purple oil wood device includes a main body 7, and a right-side end surface of the main body 7 is provided with a placement groove 71 opening to the right, and the upper side of the placement groove 71 is The main body 7 is provided with a lifting sliding cavity 74, and the main body 7 on the right side of the lifting sliding cavity 74 is provided with a stirring cavity 72 extending up and down. The top ends of the slots 71 are communicated with each other, and the lifting slider 741 is slidably connected to the inside of the lifting sliding chamber 74, and the internal thread of the lifting slider 741 is connected to a first screw 742 extending up and down. The top end of 742 is connected to the first motor 743 which is fixedly embedded in the top end wall of the lifting slide chamber 74, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap