Non-crystalline high-emulsification activity starch preparation method

An emulsifying active, non-crystalline technology, applied in the field of food processing, can solve the problems of destroying the crystalline area and reducing viscosity, and achieve the effect of reducing viscosity, high reproducibility, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

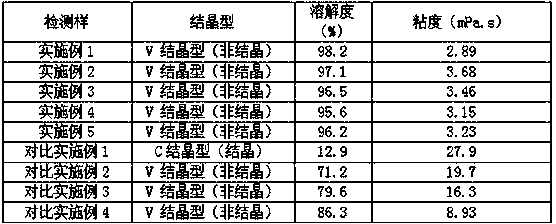

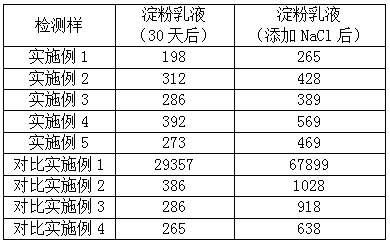

Examples

Embodiment 1

[0019] A kind of preparation method of non-crystalline high emulsification active starch, its specific steps are as follows:

[0020] (1) Add 35g of pueraria starch into 65g of water, stir to form a starch suspension, adjust its pH to 8.0, and keep it warm at 35 o C; then slowly add 1.05 g of octenyl succinic anhydride (OSA) dropwise to the starch suspension, keep the pH and temperature of the suspension constant, and keep stirring, the final modification time is 3h; the modification is over Finally, the pH value was lowered to 6.5, and the starch was washed twice with water and 75% alcohol aqueous solution to ensure that there was no residual unreacted OSA. After washing, the modified starch was kept at 45 o C drying 24h, you can get OSA modified starch.

[0021] (2) Completely gelatinize the OSA modified starch suspension obtained in step (1), the starch concentration is 3% (w / w), and the gelatinization temperature is 95 o C, gelatinization time 20 min; then use high-speed...

Embodiment 2

[0024] A kind of preparation method of non-crystalline high emulsification active starch, its specific steps are as follows:

[0025] (1) Add 35g of rice starch to 65g of water, stir to form a starch suspension, adjust its pH to 8.5, and keep it warm at 30 o c. Then 0.75 g OSA was slowly added dropwise to the starch suspension while keeping the pH and temperature of the suspension constant while stirring. The final modification time was 4 h; Wash the starch twice with water and 75% alcohol solution to ensure that there is no residual unreacted OSA; after washing, the modified starch was washed at 45 o The OSA modified starch can be obtained by drying at C for 24 h.

[0026] (2) Completely gelatinize the OSA modified starch suspension obtained in step (1), the starch concentration is 5% (w / w), and the gelatinization temperature is 95 o C, gelatinization time 20 min. Then apply a high-speed shearing machine and a high-pressure homogenizer to the OSA modified starch gelatiniz...

Embodiment 3

[0029] A kind of preparation method of non-crystalline high emulsification active starch, its specific steps are as follows:

[0030] (1) Add 35g of potato starch into 65g of water, stir to form a starch suspension, adjust its pH to 8.0, and keep it warm at 35 o c. Then 1.05 g of OSA was slowly added dropwise to the starch suspension, keeping the pH and temperature of the suspension constant while stirring, and the final modification time was 3.5 h; after the modification, the pH value was lowered to 6.5, And wash the starch twice with water and 75% alcohol aqueous solution to ensure that there is no residual unreacted OSA. After washing, the modified starch was washed at 45 o The OSA modified starch can be obtained by drying at C for 24 h.

[0031] (2) Completely gelatinize the OSA modified starch suspension obtained in step (1), the starch concentration is 3% (w / w), and the gelatinization temperature is 95 o C, gelatinization time 20 min. Then apply a high-speed shear an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com