A kind of preparation method of attapulgite modified lignin type polyurethane material

A technology of polyurethane material and attapulgite, which is applied in the field of preparation of attapulgite-modified lignin-type polyurethane material, can solve the problems of reducing the flexibility and elongation of polyurethane, achieve improved mechanical properties, low price, and avoid stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

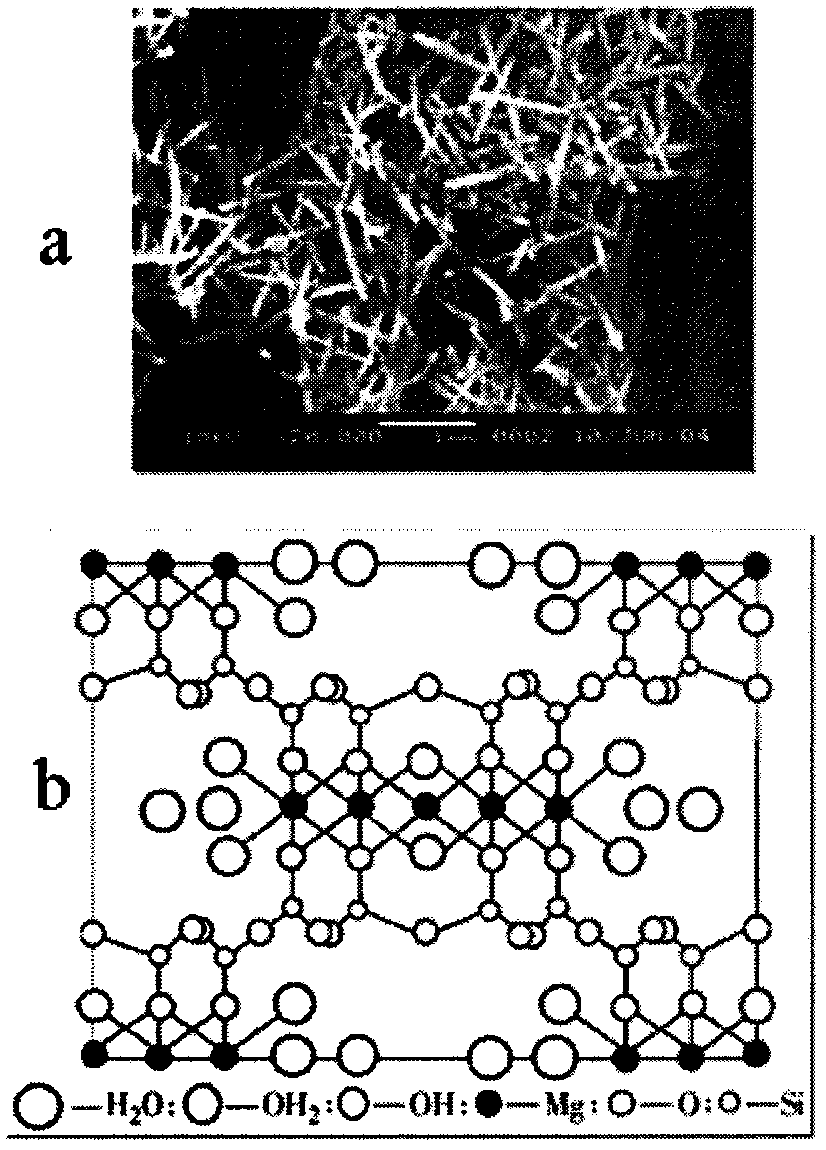

[0031] (1) Preparation of acid-treated attapulgite: Weigh 50g of the original attapulgite, add 250ml of distilled water containing 25ml of hydrochloric acid, stir at 50°C for 3 hours, filter, wash and dry, then grind into powder to obtain acid-treated attapulgite HAT.

[0032] (2) Weigh 6g of dry alcoholyzed lignin and dissolve it in 100ml of dimethylformamide (DMF), then add 100g of polyethylene glycol PEG 1000 and stir at 60°C for 30min to make it fully mixed. Then add 2g of HAT to compound to obtain polyol.

[0033] (3) The compounded polyol was uniformly mixed with 1.5 g of dibutyltin dilaurate, 2.2 g of triethylenediamine, and 10.6 g of trimethylolpropane to obtain a mixed solution.

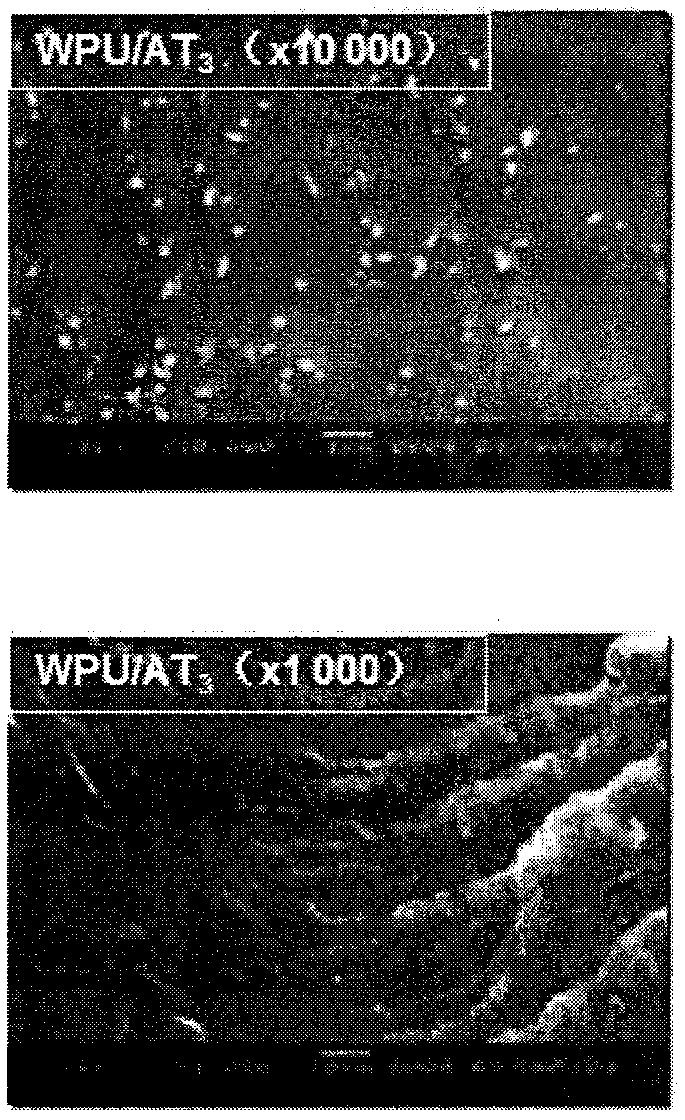

[0034] (4) Add a certain amount of toluene diisocyanate to the mixed solution in step (3), adjust the isocyanate index (n(-N°CO):n(-OH)) to 1:1.5, and react under closed stirring at 90°C for 30 minutes, After the reaction was complete, the obtained resin was added to deionized water contai...

Embodiment 2

[0036] (1) Preparation of acid-treated attapulgite: Weigh 50 g of the original attapulgite, add 250 ml of distilled water containing 25 ml of hydrochloric acid, stir at 60°C for 3 hours, filter, wash and dry, then grind into powder to obtain acid-treated attapulgite HAT.

[0037] (2) Weigh 15g of dry alkali lignin and dissolve it in 100ml of toluene, then add 100g of polycaprolactone diol and stir at 60°C for 30min to make it fully mixed. Then add 6g of HAT, compound to obtain complex polyol.

[0038] (3) The compounded polyol was uniformly mixed with 1.6 g of stannous octoate, 2.4 g of triethylenediamine, and 11.5 g of dipropylene glycol to obtain a mixed solution.

[0039] (4) Add a certain amount of diphenylmethane diisocyanate to the mixed solution in (3), adjust the isocyanate index (n(-NCO):n(-OH)) to 2:1, and react under closed stirring at 70°C for 60min After the reaction is complete, add deionized water containing NaOH to the obtained resin, and emulsify for 30 minu...

Embodiment 3

[0041] (1) Preparation of acid-treated attapulgite: Weigh 50 g of the original attapulgite, add 250 ml of distilled water containing 25 ml of hydrochloric acid, stir at 60°C for 3 hours, filter, wash and dry, then grind into powder to obtain acid-treated attapulgite HAT.

[0042] (2) Weigh 15g of dry acid lignin and dissolve it in 100ml of acetone, then add 100g of polyethylene adipate diol and stir at 60°C for 30min to make it fully mixed. Then add 30gHAT, and obtain compound polyol after dispersion.

[0043] (3) Mix the compound polyol with 1.6g of stannous octoate, 2.4g of triethylenediamine, and 11.5g of castor oil to obtain a mixed solution.

[0044] (4) Add a certain amount of xylylene diisocyanate to the mixed solution in (3), adjust the isocyanate index (n(-NCO):n(-OH)) to 2:1, and react under closed stirring at 90°C After 30 minutes, after the reaction is complete, add deionized water containing NaOH to the obtained resin, and emulsify for 30 minutes. The prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com