Anti-theft nut for iron tower

An anti-theft nut and iron tower technology, applied in nuts, bolts, threaded fasteners, etc., can solve problems such as safety accidents, facility losses, and easy disassembly by others.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

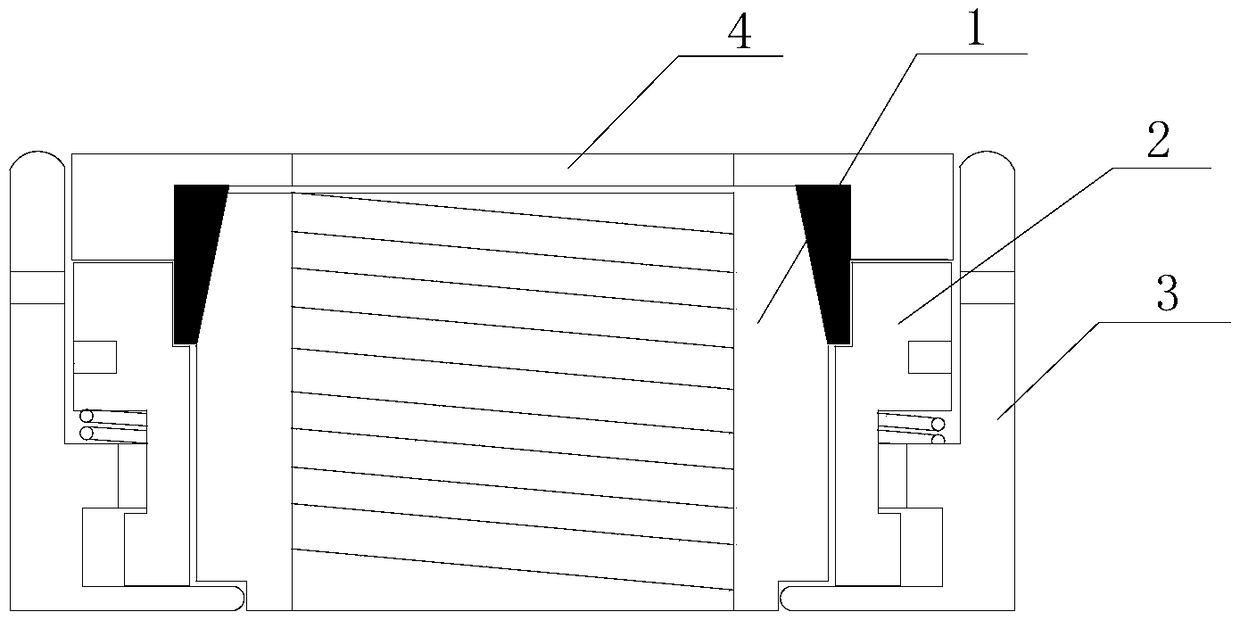

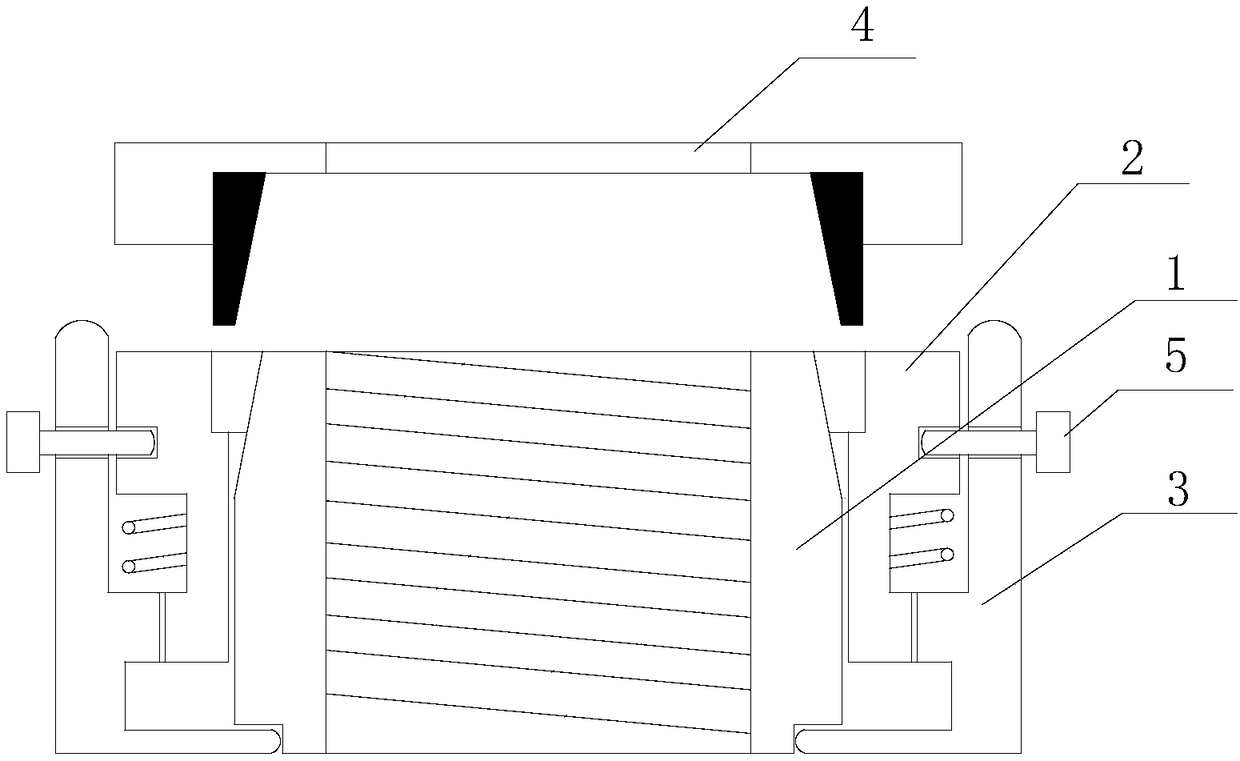

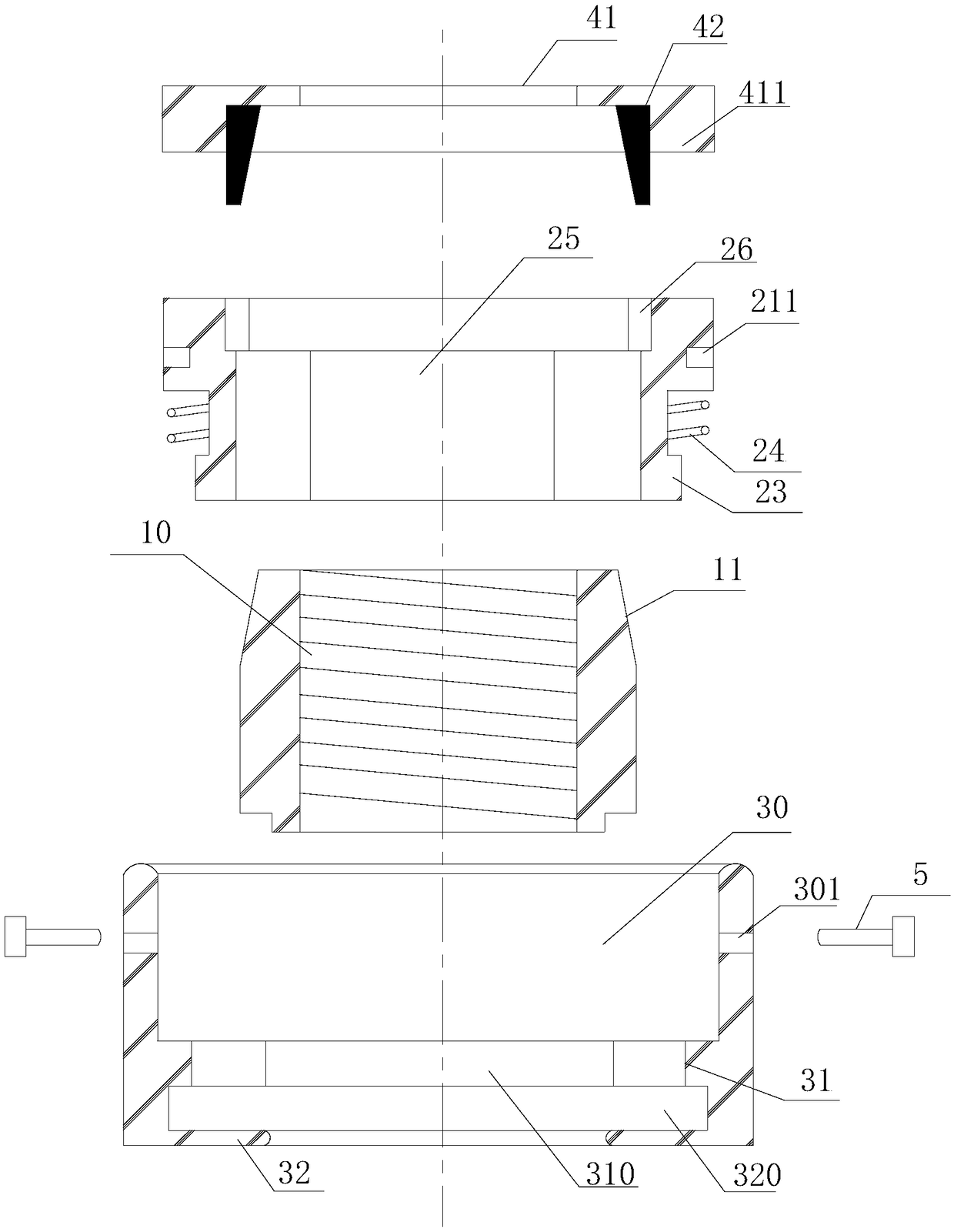

[0016] refer to Figure 1 to Figure 5 , an anti-theft nut for an iron tower according to the present invention is characterized in that it includes a hexagonal nut body 1, an anti-theft drive assembly 2, an outer casing 3 and a squeeze locking assembly 4, and the hexagonal nut body 1 is installed on the outer casing 3 through the anti-theft drive assembly 2 Inside, the lower end of the outer cover 3 extends inwardly with a flange 32 that matches the hexagonal nut body 1, and an anti-theft drive assembly 2 is arranged between the hexagonal nut body 1 and the outer cover 3, and the anti-theft drive assembly 2 and the outer cover 3 is provided with a spring 24, the center of the anti-theft driving assembly 2 is provided with a first driving hexagonal cavity 25, and the first driving hexagonal cavity 25 is installed in cooperation with the hexagonal nut body 1, and the bottom of the anti-theft driving assembly 2 A first hexagonal body 23 is provided, and the inner wall of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com