Thinning and reversing punch and its design method

A thinning hole turning and design method technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large thinning hole turning and inability to process thinning amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

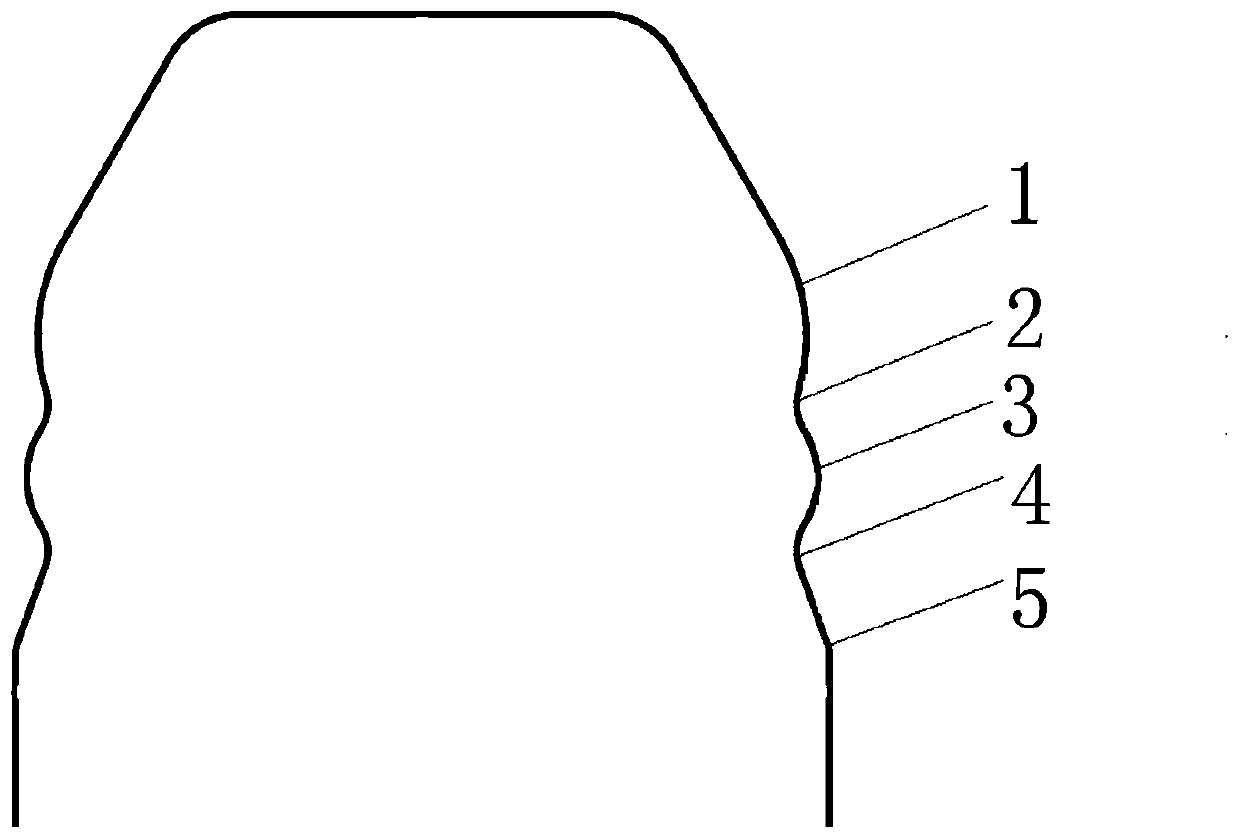

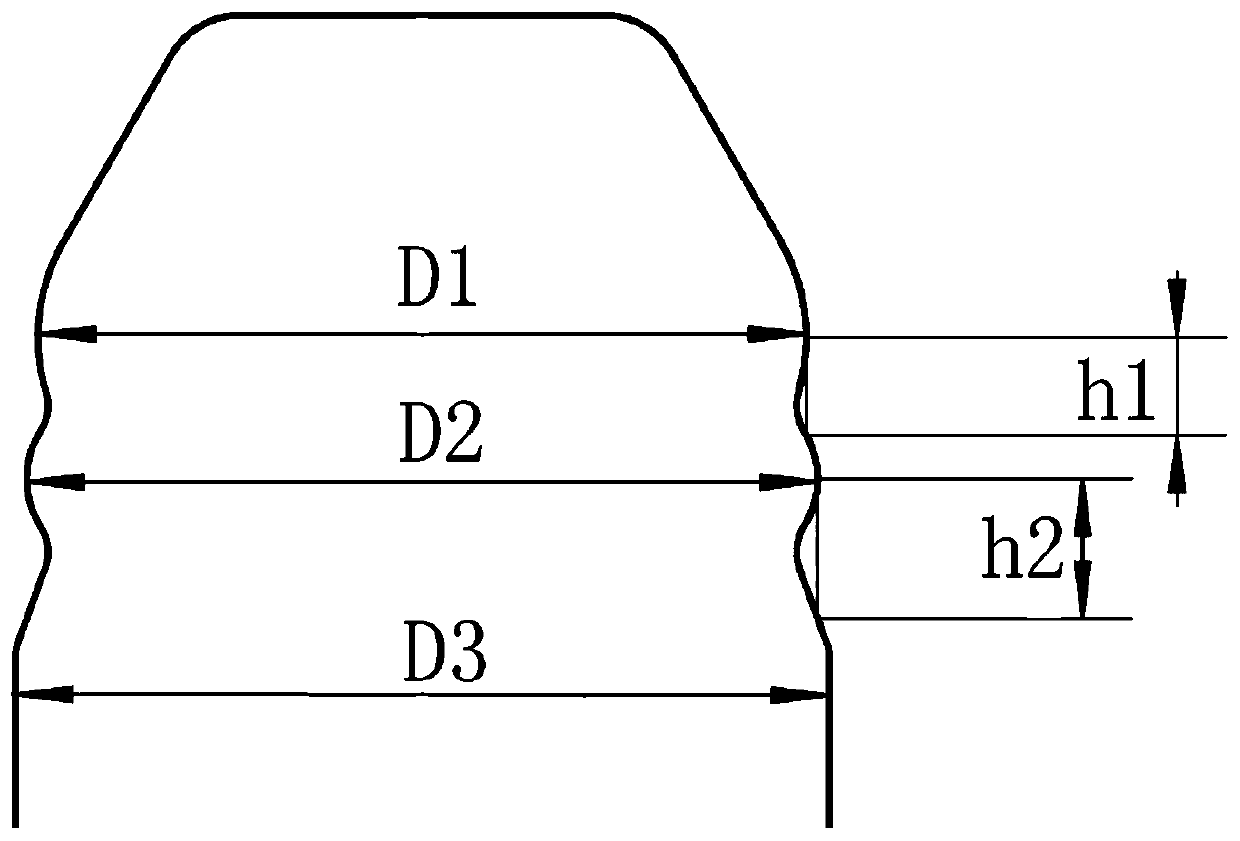

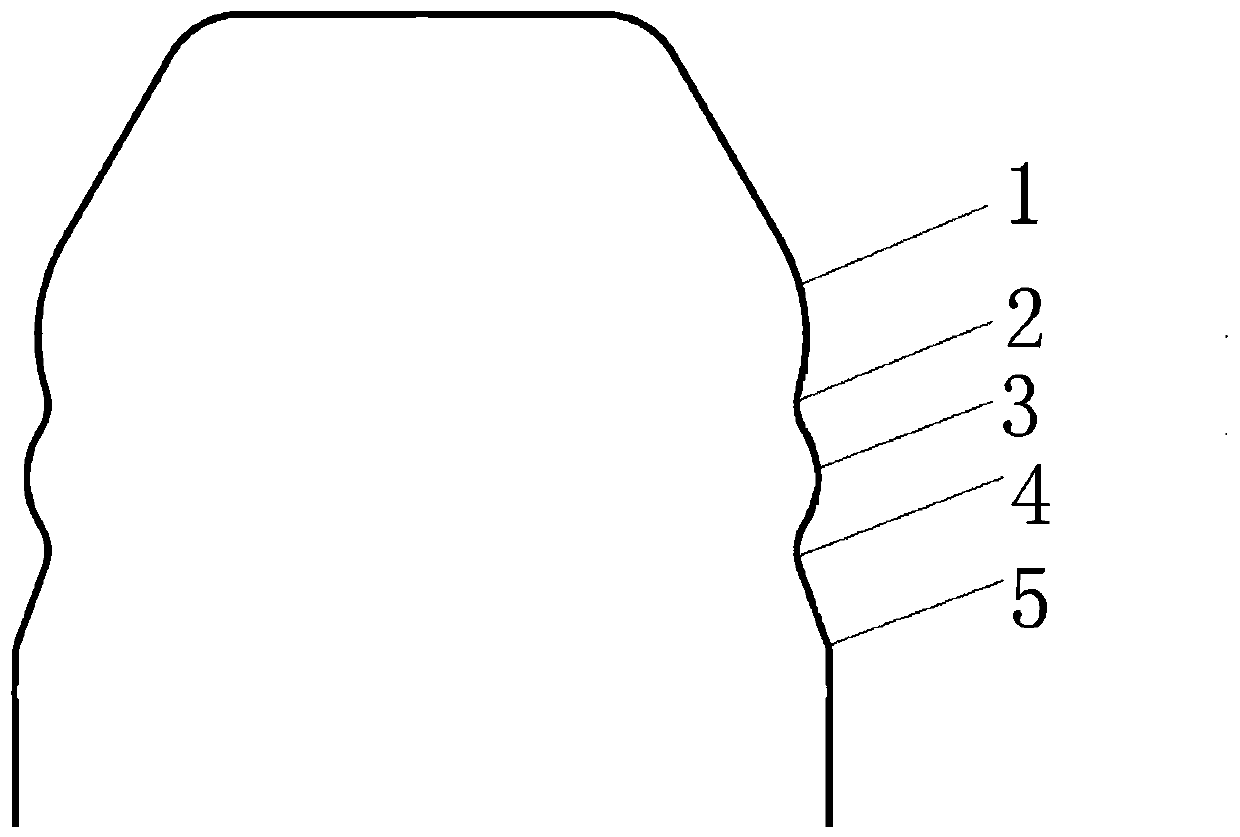

[0031] figure 1 It is a structural schematic diagram of the thinning and boring punch of the preferred embodiment of the present invention; figure 2 It is a schematic diagram of the structure size of the thinning and boring punch in the preferred embodiment of the present invention.

[0032] Such as figure 1As shown, the thinning and reaming punch of this embodiment includes a first punch section 1 located at the starting end of the punch, a second punch section 3 located downstream of the first punch section 1, and a second punch section 3 located downstream of the first punch section. The first transition section 2 between section 1 and the second punch section 3, the third punch section 5 located downstream of the second punch section 3, and the third punch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com