A double-sided corrugated paper forming roll set

A technology for corrugated paper and forming rollers, applied in the direction of machining/deformation, etc., can solve the problem of oversized corrugated paper production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

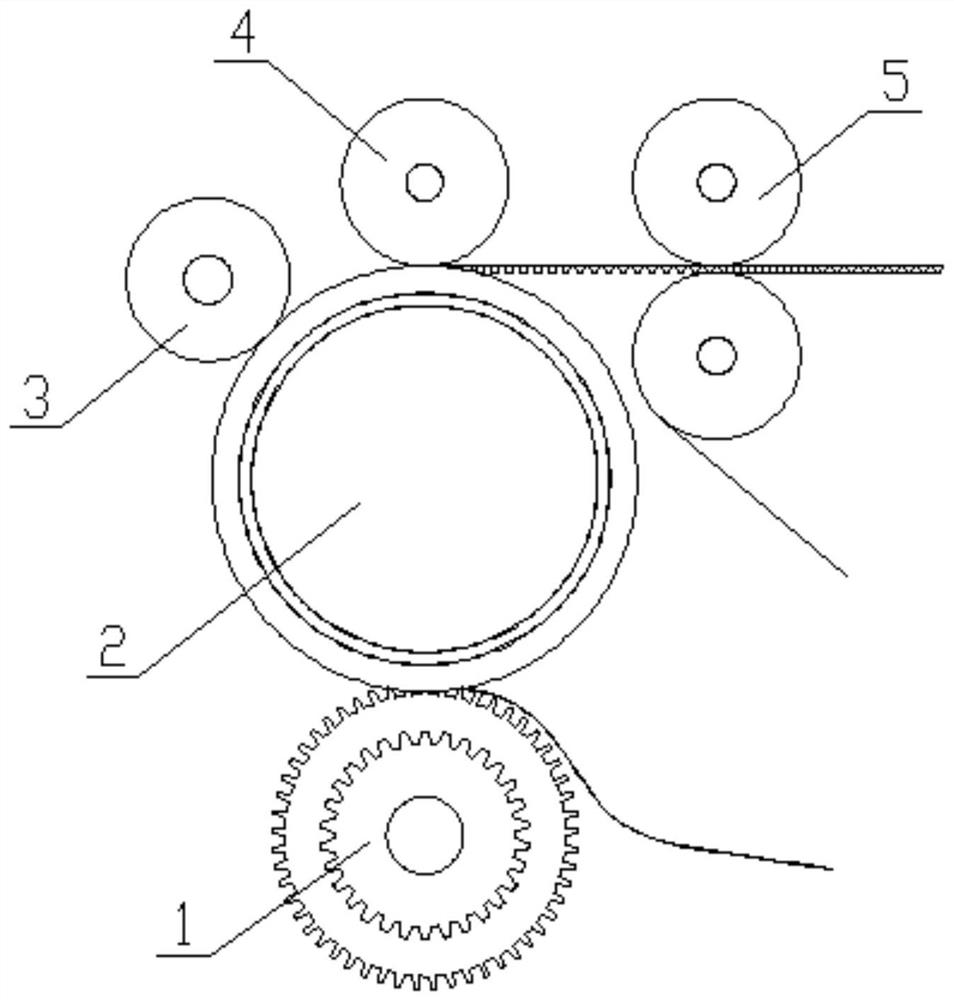

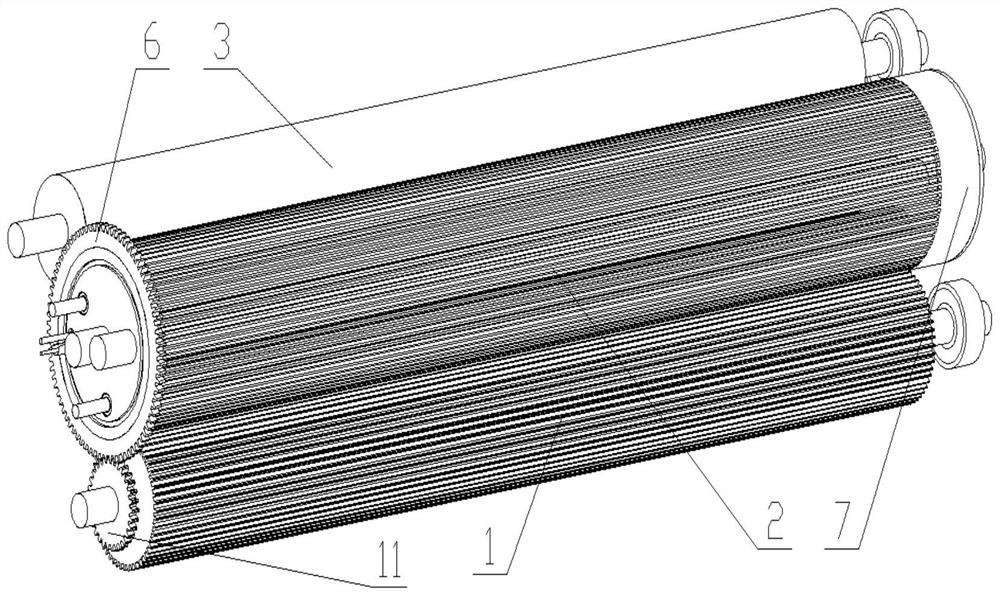

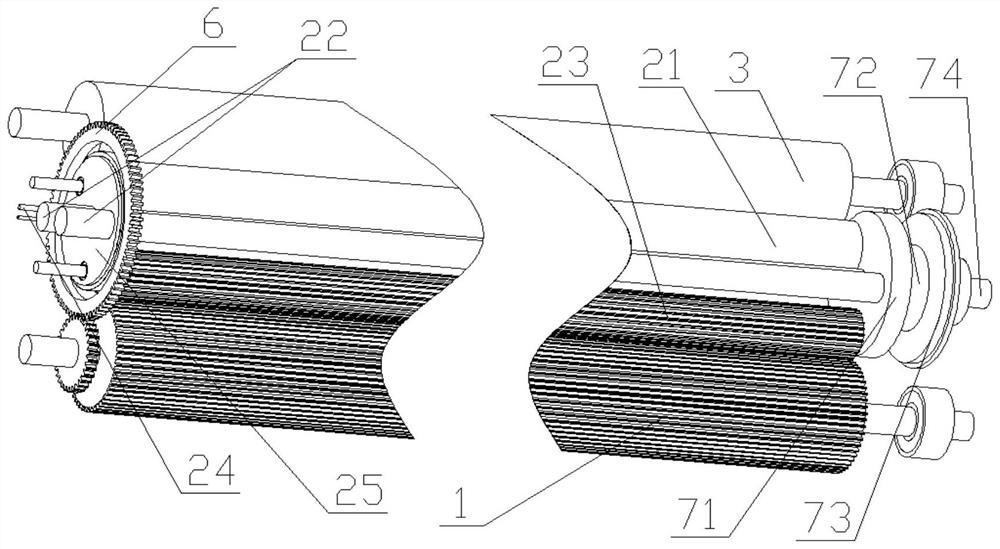

[0029] like Figure 1 to Figure 8 As shown; a double-sided corrugated paper forming roll group, including a heated corrugated roll 1, a corrugated forming mechanism 2 and an upper paper surface sticking roll 4, the heated corrugated roll 1 is arranged below the corrugated forming mechanism 2, and the heated corrugated roll 1 and the corrugated forming mechanism 2 cooperate with each other to form the corrugated paper core by hot pressing. The outer rubber roller 3 for gluing the corrugated paper core is arranged on one side of the corrugated forming mechanism 2, and the upper paper sticking roller 4 is arranged above the corrugated forming mechanism 2. , the upper paper pasting roller 4 and the corrugated forming mechanism 2 cooperate with each other to paste the corrugated paper core and the face paper, and the side of the upper paper pasting roller 4 away from the outer upper rubber roller 3 is provided with two mutually matched lower paper surfaces Pressing roller 5; the co...

Embodiment 2

[0032] On the basis of Example 1, the corrugated forming barrel 8 includes a left sleeve 81, a right sleeve 83 and a shaping rod 82 that cooperates with the heated corrugating roller 1 to form a corrugated core. The left sleeve 81 and the right sleeve 83 pass through several A sizing rod 82 is connected, and the side of the sizing rod 82 near the inner pressure roller 23 is provided with a positioning arc groove 84, and the inner pressure roller 23 is provided with a positioning table 85 that cooperates with the positioning arc groove 84; The diameter of the roller 23 is greater than the radius of the corrugated forming barrel 8; it includes a unilateral sleeve 76 and a bolt 77, the rotating plate 73 is connected with the power roller 74 through the unilateral sleeve 76, and the rotating plate 73 is connected to the unilateral sleeve 76 through the bolt 77 Connected; one side of the outer upper rubber roller 3 is provided with an equalizing roller matched with it; the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com