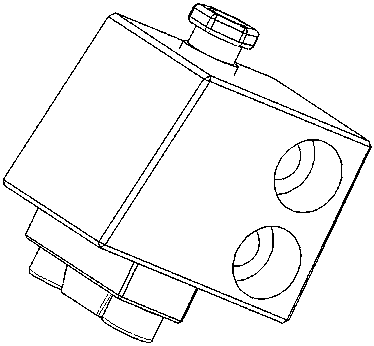

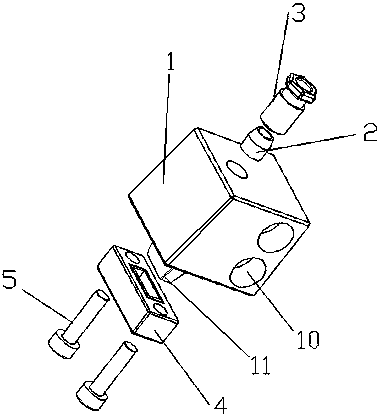

Self-sealing square hose and circular hose conversion joint resistant to medium-high pressure and sealing and connecting methods for hoses

A conversion joint and self-sealing technology, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of complex joint structure, high cost, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

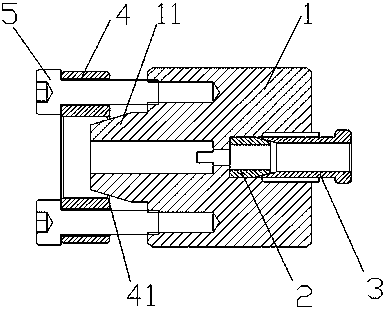

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0027] A sealing connection method for a circular hose, involving a sleeve, a pressure sleeve and a circular hose. The hole is set in cooperation with the cone, and the method includes the following steps:

[0028] Step 1. The circular hose passes through the gland and is inserted into the sleeve;

[0029] Step 2: Move the pressure sleeve to press it tightly with the sleeve, so that the cone of the sleeve shrinks under pressure, and the section of the circular hose inside the cone is squeezed and deformed to complete the connection and sealing of the circular hose.

[0030] A sealing connection method for a square hose, involving a square hose, a connection block with a hollow quadrangular pyramid structure, and a briquetting block process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com