An automobile engine system pipeline airtight performance testing equipment

A technology of automobile engine and testing equipment, which is used in the testing of fluid tightness, the use of liquid/vacuum for liquid tightness measurement, and the testing of machinery/structural components. It can solve problems such as comparison of properties and increase the difficulty of pipeline processing, so as to achieve the effect of increasing the amount of deformation and increasing the efficiency of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

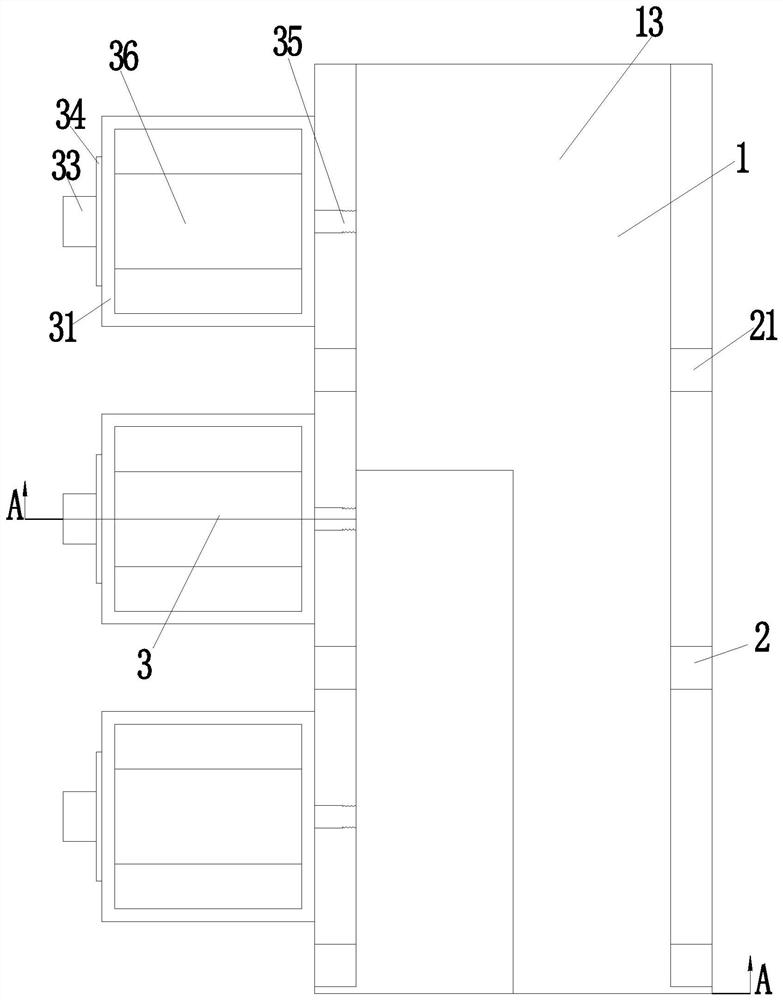

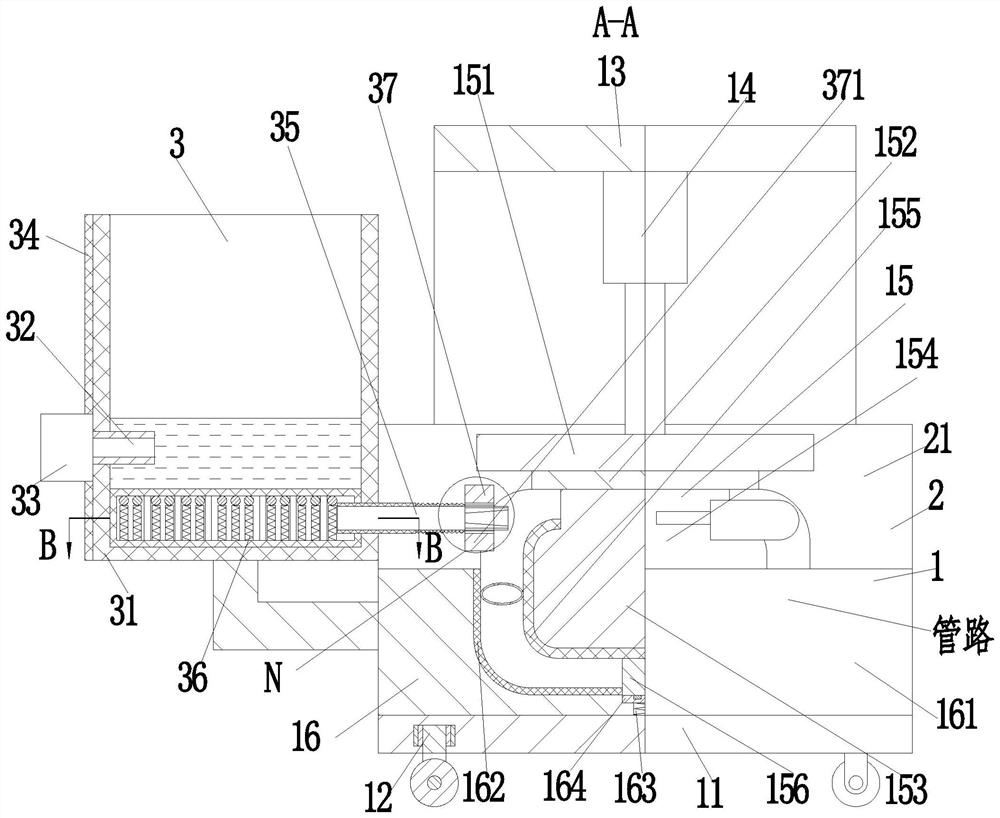

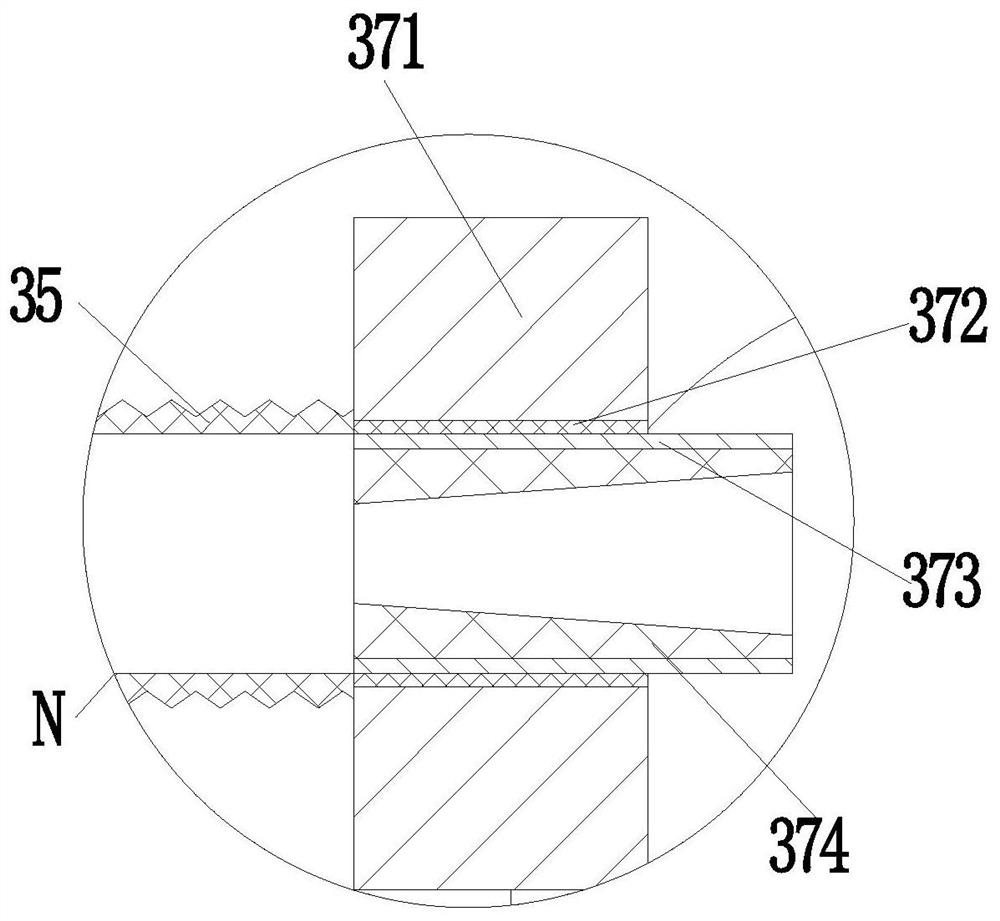

[0033] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0034] An automobile engine system pipeline airtight performance testing equipment, including a fixing device 1, an air intake device 2 and an airbag device 3, the upper end of the fixing device 1 is fixedly installed with an air inlet device 2, and the left side of the fixing device 1 is fixedly installed with an airbag Device 3; where:

[0035] The fixing device 1 includes a rectangular table 11, a universal wheel 12, an inverted L-shaped plate 13, an electric cylinder 14, a pressure column 15, a fixing frame 16 and a buckle 17, and the front and rear sides of the lower end of the rectangular table 11 are symmetrically installed with Universal wheels 12, an inverted L-shaped plate 13 is fixedly installed on the upper end of the front side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com