Hydrovalve

A technology for water valves and valve cores, applied in the direction of lift valves, valve details, valve devices, etc., can solve the problems of heavy weight, difficult sealing of the joint between the valve body and the pipeline, waste of resources and energy, etc., and achieve convenient pipelines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

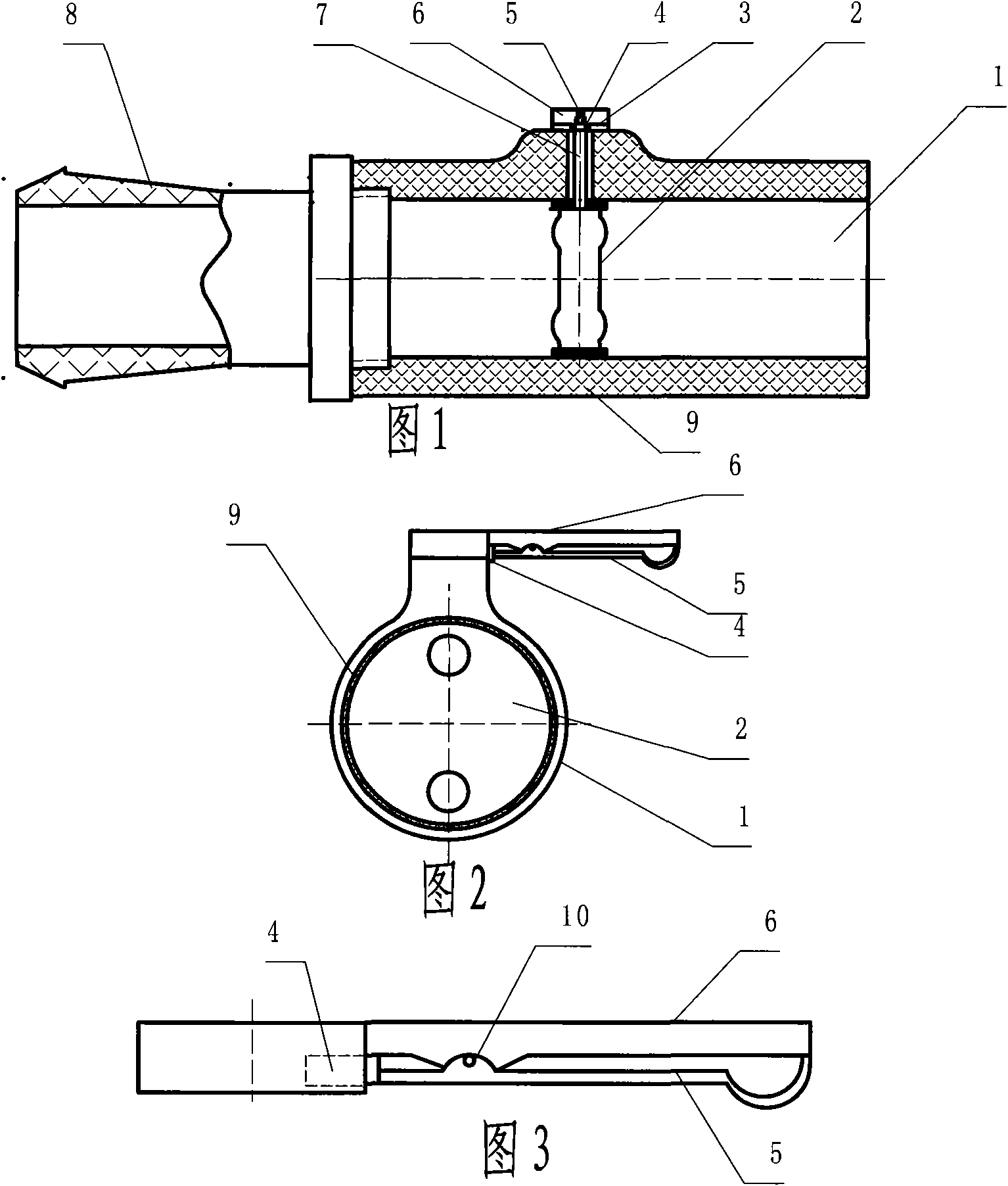

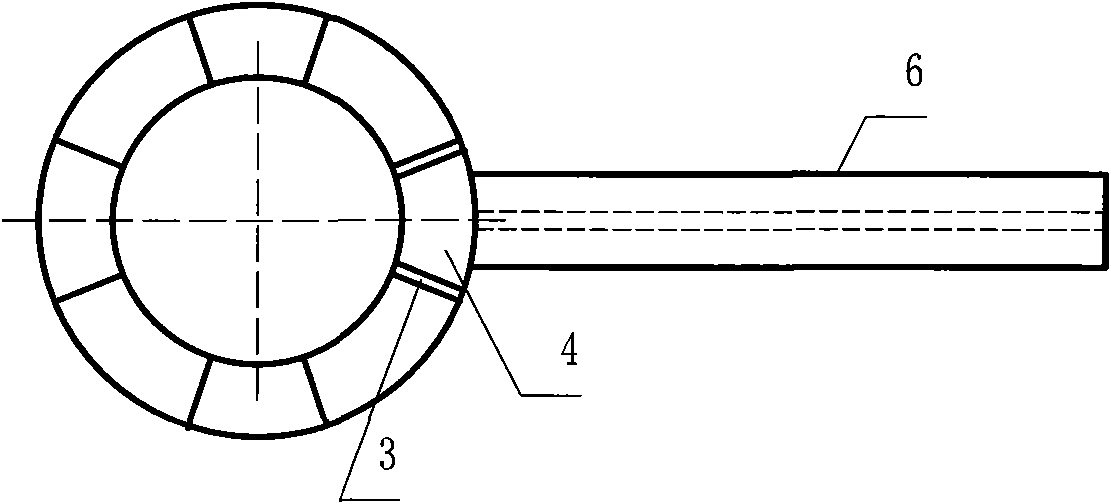

[0016] Referring to the accompanying drawings, this embodiment includes a valve body 1, a valve core 2, and a valve core operating handle 6. One end of the valve body connected to the water source is threaded, and the end of the valve body connected to the irrigation pipeline is a slope surface 8. The spool is a butterfly type, and a sealing ring 9 is provided between the spool and the valve body. One end of the valve body connected to the irrigation pipeline is a valve body section with a sloped surface and the middle valve body section is integrated, and the valve core operating handle is provided with a valve core positioning locking device 3, 4, 5. The slot 3 is ring-shaped Multi-slot, fixed on the valve body, the positioning pin 4 is connected with the pull rod 5, the pull rod 5 is hinged with the lower part of the valve core operating handle 6, and its head is convex, hold the valve core operating handle 6 and squeeze the head of the pull rod 5 The protrusion on the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com