A method for predicting ultra-high cycle fatigue life of high-strength titanium alloy electron beam welded joints

A technology of fatigue life prediction and electron beam welding, which is applied to the analysis of solids, materials, and instruments using sound waves/ultrasonic waves/infrasonic waves, and can solve problems such as inability to accurately predict ultra-high cycle fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A high-strength titanium alloy electron beam welded structure ultra-high cycle fatigue life prediction model, comprising the following steps:

[0020] (1) Take 10 high-strength titanium alloy electronic plastic welding joints, and mark them as samples 1-10 in turn, conduct ultra-high-cycle fatigue tests on samples 1-10 by ultrasonic fatigue method, test frequency 20kHz, and obtain sample 1 The stress amplitude Δσ of ~10 and its corresponding value of fatigue life N, the specific values are shown in Table 1;

[0021] (2) Observing the fatigue fractures of the high-strength titanium alloys of samples 1 to 10 with a scanning electron microscope, and measuring the electron beam welding pore size a of samples 1 to 10 Inc , see Table 1 for specific values; and calculate the effective threshold of fatigue crack growth Where μ is the material shear modulus, b is the material lattice Burgers vector;

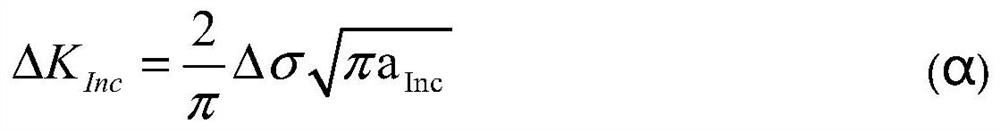

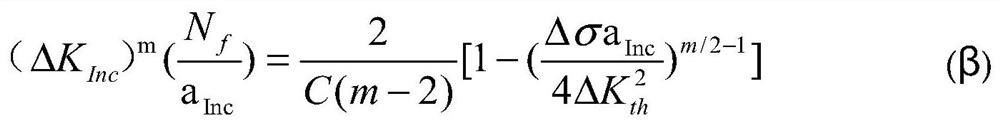

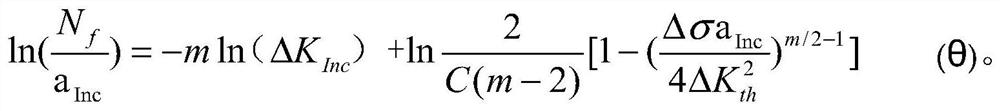

[0022] According to formula (α), formula (α) is: In order to calculate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com