Preparation method of novel honeycomb-shaped formed active carbon

A technology of forming activated carbon and honeycomb, which is applied in the field of activated carbon, can solve the problems of low mixing efficiency and complicated operation steps, and achieve the effect of reducing working time and improving mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

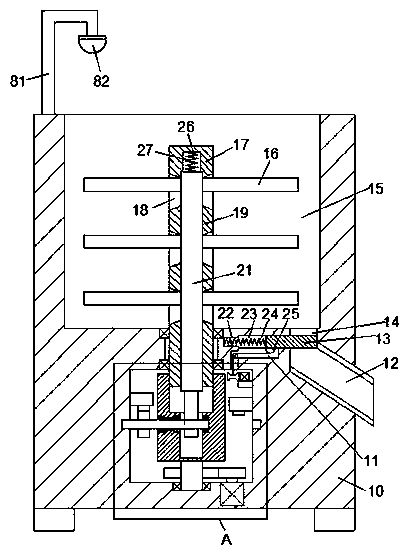

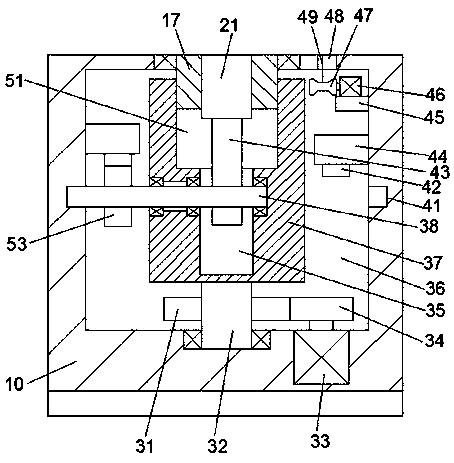

[0012] Combine below Figure 1-2 The present invention will be described in detail.

[0013] refer to Figure 1-2 , according to an embodiment of the present invention, a novel method for preparing honeycomb-shaped activated carbon, comprising a main frame body 10, a mixing chamber 15 is provided in the top end surface of the main frame body 10, and all the parts on the lower side of the mixing chamber 15 The main frame body 10 is provided with a circular driving chamber 36, and a mixing shaft 17 is installed in rotation between the circular driving chamber 36 and the mixing chamber 15, and the mixing shaft 17 extends into the mixing chamber 15. And the bottom end face is extended up and down to be provided with contraction groove 19, and the contraction arm 21 is installed in the described contraction groove 19 slidingly, and described contraction groove 19 left and right sides is symmetrically provided with a plurality of groups of open cavities 18, and described open cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com