Novel corrosion resistant cement and application thereof

A corrosion-resistant and novel technology, applied in the field of corrosion-resistant cement, can solve the problems of cumbersome operation steps and low mixing efficiency, and achieve the effect of reducing working hours and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

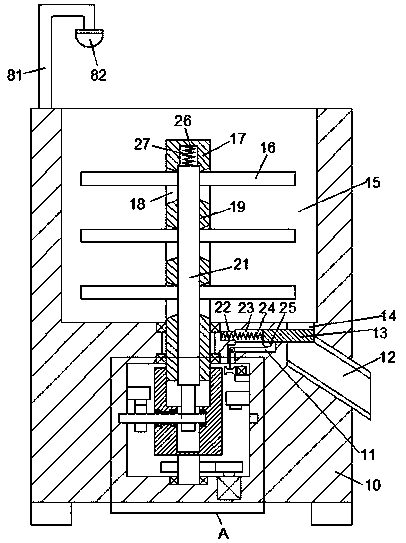

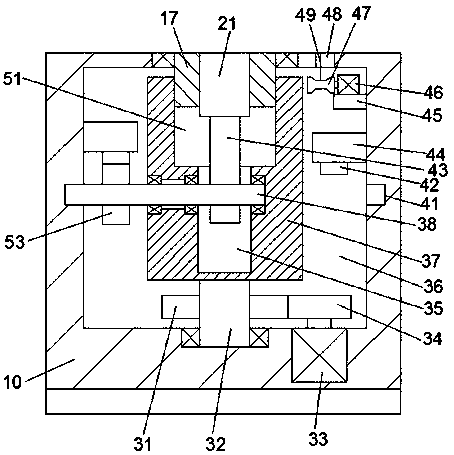

[0012] Combine below Figure 1-2 The present invention will be described in detail.

[0013] refer to Figure 1-2 , a novel corrosion-resistant cement and its application according to an embodiment of the present invention, comprising a shell 10, a stirring cavity 15 is arranged in the top end surface of the shell 10, and the stirring cavity 15 under the The housing 10 is provided with an annular driving chamber 36, and a stirring shaft 17 is installed in rotation between the annular driving chamber 36 and the stirring chamber 15, and the stirring shaft 17 extends into the stirring chamber 15 and inside the end face of the bottom extend up and down to be provided with a storage cavity 19, and a storage arm 21 is installed in the sliding fit of the storage cavity 19, and a plurality of groups of slots 18 are symmetrically arranged on the left and right sides of the storage cavity 19, and the slots 18 A stirring sheet 16 is installed in sliding fit, and the stirring sheet 16 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com