Disc filter water-saving sewage collection tank

A disc filter and sewage collection tank technology, which is applied to fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve waste, sewage collection tanks cannot perform secondary filtration, and there is no water-saving sewage collection tank. and other problems to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the implementation manners of the present invention will be explained in detail below in conjunction with the accompanying drawings.

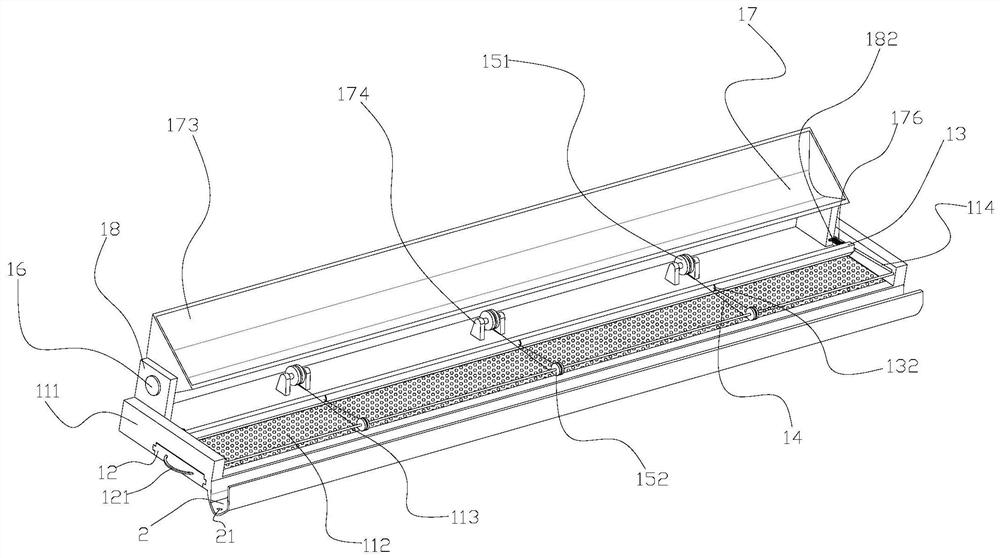

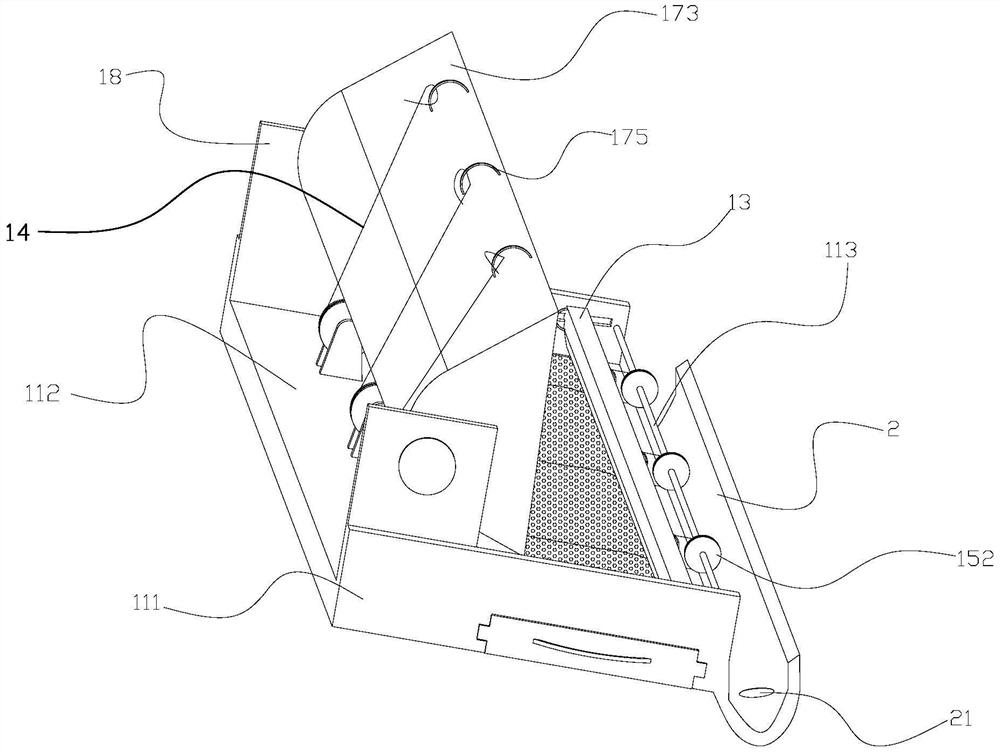

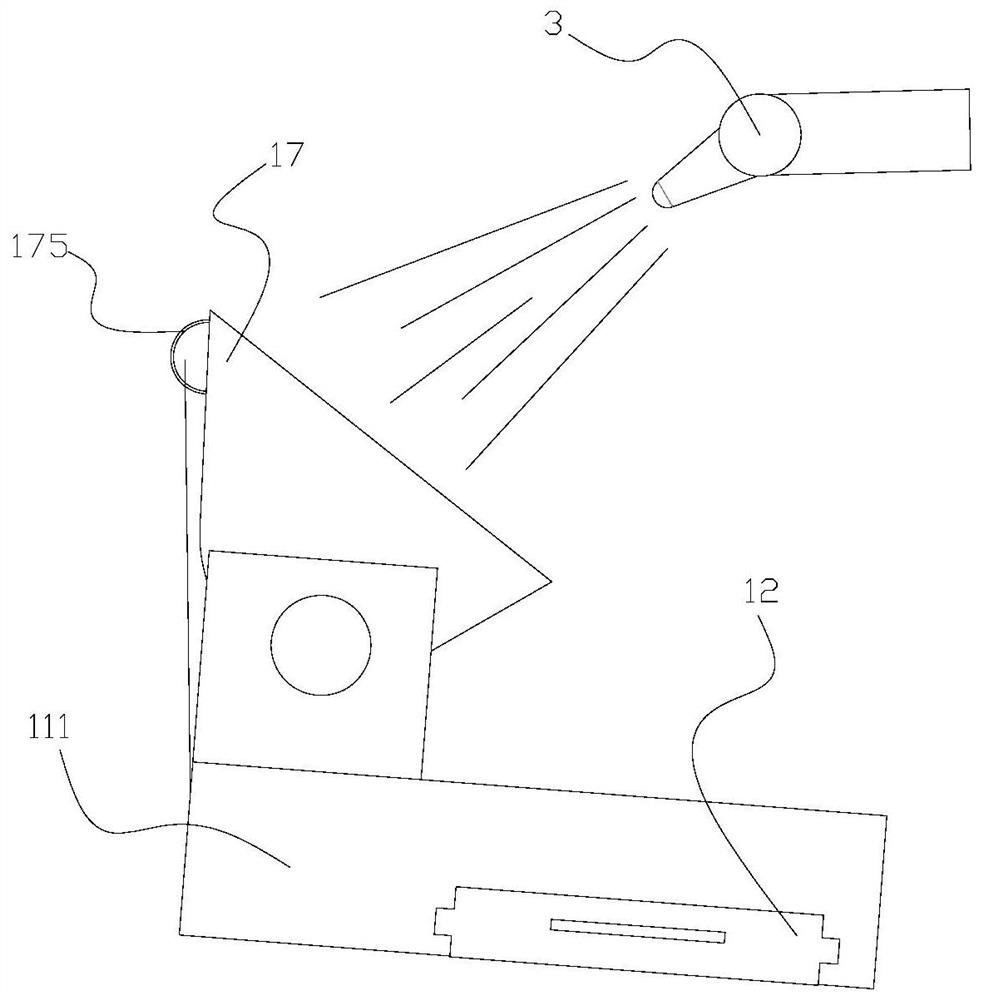

[0041] as attached figure 1 to attach Figure 17 As shown, the present invention includes a filter tank 1 and a sewage tank 2. The filter tank 1 includes a tank frame 11, a filter plate 12, a scraper 13, a pull wire 14, a lead wheel I15, a lead wheel II151 and a water collection tank 17. The tank frame 11 includes two vertical plates 111 and a horizontal plate 112. The vertical plates 111 are arranged on the front and rear sides of the horizontal plate 112. In order to discharge debris better, the trough frame 11 is inclined downward from left to right. The right end of the tank frame 11 is connected to the sewage discharge tank 2, and the sewage discharge tank 2 is inclined downward from back to front. In order to better gather debris, the sewage discharge tank 2 is U-shaped, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com