Ammunition belt loader

A technology of chain loading machine and ammunition ammunition, which is applied in the direction of ammunition supply, weapon accessories, offensive equipment, etc. It can solve the problems of low efficiency and achieve the effect of convenient maintenance and use, simple structure and fast loading of ammunition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

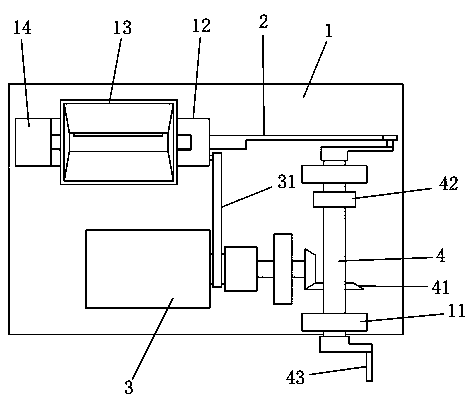

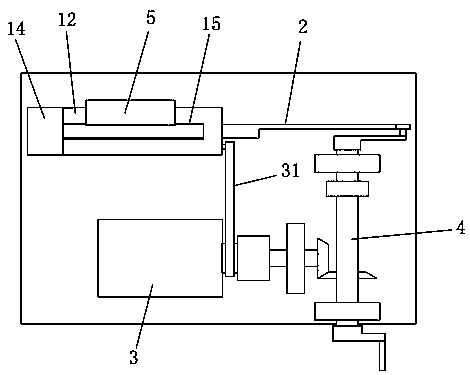

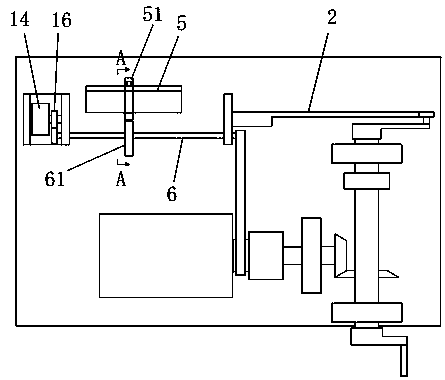

[0023] Example 1: as Figures 1 to 6 As shown in the figure, an ammunition chain loader includes a base 1 on which a first bracket 11 and a second bracket 12 are arranged, and a guide with a width and depth equal to the outer diameter of the ammunition is arranged on the second bracket. Slot 15, the guide slot is provided with a push rod 2 that moves along the guide slot, the second bracket is provided with an ammunition box 13 whose outlet is aligned with the guide slot, and the bullet box outlet can only drop one ammunition at a time 7. A baffle 5 for blocking the exit is provided at the exit of the bullet box, a rocker 51 is hinged at the rear end of the baffle, and the middle of the rocker is hinged on the side wall of the second bracket; the bottom of the second bracket is hinged There is a rotating shaft 6 driven to rotate by a driving mechanism, and a cam 61 for pushing a rocker is fixed in the middle of the rotating shaft; The drive gear provided at the end of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com