Fodder trough for cows and sheep

A feed trough, cattle and sheep technology, applied in the field of cattle and sheep feed trough, can solve the problems that affect the efficiency of spreading materials, difficult to clean, and the trough cannot be moved, etc., to achieve the effect of convenient cleaning, improving efficiency and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

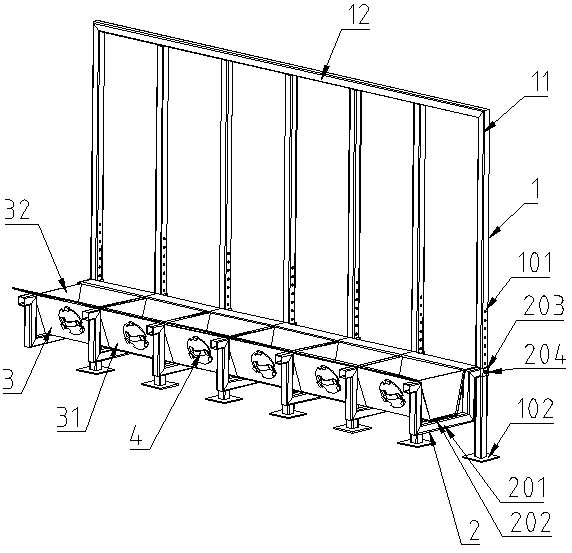

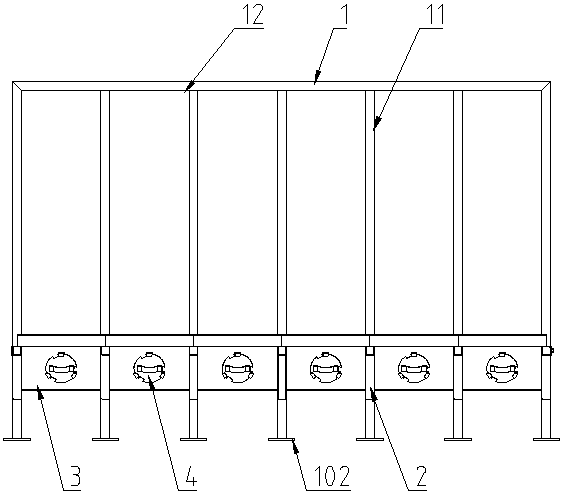

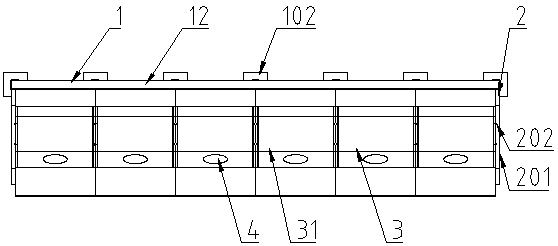

[0024] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

[0025] Such as Figure 1~Figure 6 As shown, a feed trough for cattle and sheep includes a frame body 1, and the frame body 1 includes a vertical rod 11 and a connecting rod 12, and the top and the bottom of the vertical rod 11 are respectively provided with a connecting rod 12 by welding, so A series of installation holes 101 are evenly distributed on the left and right sides of the lower part of the vertical bar 11, and the bottom of the vertical bar 11 is fixedly provided with a foot plate 102 by welding, and the frame body 1 is fixed on the ground via the foot plate 102 through anchor bolts ground, so that the frame body 1 can become a part of the pen, and the utilization rate of the frame body 1 is improved; The front part of the adjustable rod 2 is provided with a concave rod 201, and the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com