Polishing device for spherulitic graphite pipe

A ball ink and bump technology, applied in the direction of grinding machines, grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems of increasing working time and wasting production resources, so as to save working time and production resources The effect of effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through the accompanying drawings and embodiments. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention.

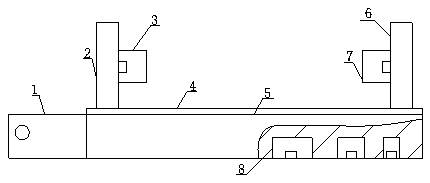

[0011] Such as figure 1 As shown, a grinding device for ductile ink tubes used in the present invention includes a controller 1, a support column I2, a bump I3, a guide rail 4, a base 5, a support column II6, a bump II7 and a bump III8, and the controller 1 Fixedly installed on one side of the base 5, the guide rail 4 is installed on the surface of the base 5, the support column I2 is installed on the guide rail 4, the bump I3 is fixedly installed on the support column I2, and the support column II6 is installed on the guide rail 4, The bump II7 is fixedly installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com