An automatic applicator mechanism for partial discharge detection coupling agent

A technology of partial discharge detection and couplant, which is applied in the direction of testing dielectric strength, etc., can solve the problems of low work efficiency, achieve low production costs, solve precise control, and have simple and compact structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

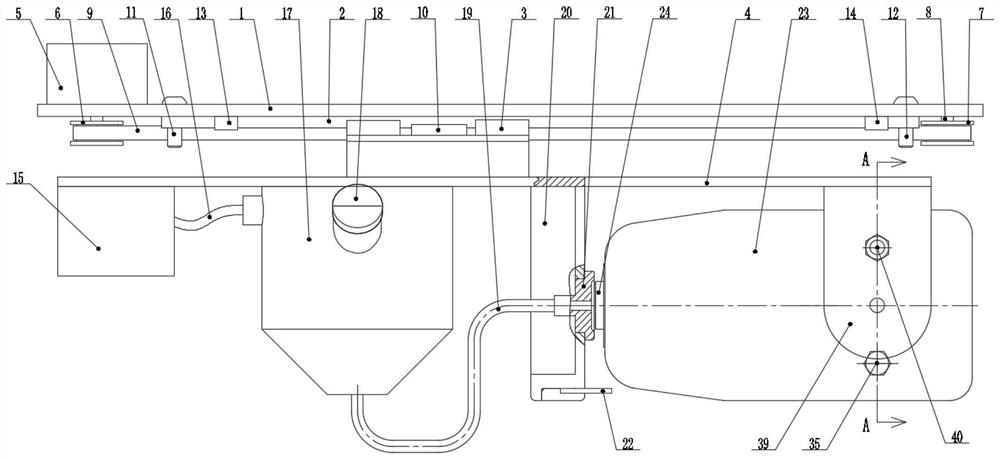

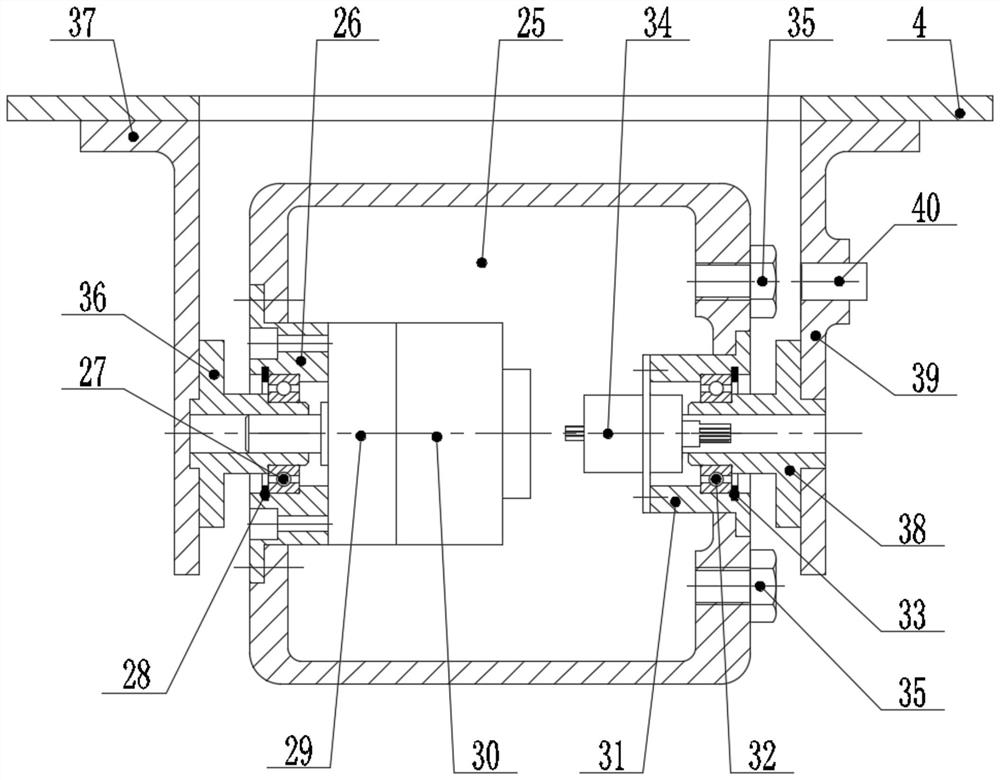

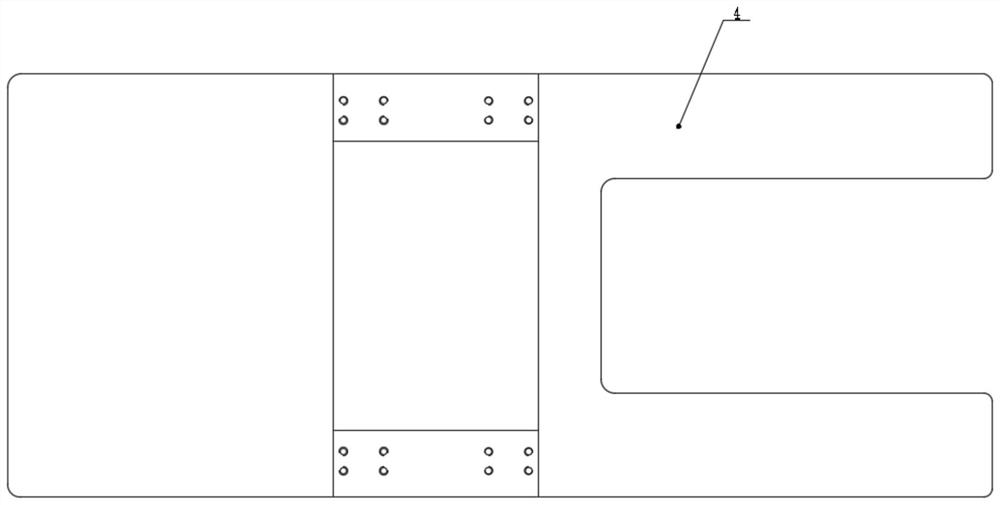

[0031] The automatic smearing mechanism for partial discharge detection coupling agent of the present invention comprises a fixed plate 1, the lower end of the fixed plate 1 is provided with a guide rail 2, the lower end of the guide rail 2 is connected with a slider 3, the lower end of the slider 3 is connected with a sliding seat 4, and the sliding seat 4 is connected with a The first drive unit, the lower end of the sliding seat 4 is provided with an air pump 15, a couplant container 17, a bracket 20 and a partial discharge fixing seat. A couplant delivery pipe 19 is connected between them, and the couplant delivery pipe 19 is connected to a couplant head 21 after passing through the bracket 20. The couplant head 21 is provided with a discharge port, the bracket 20 and the local discharge fixing seat are arranged side by side, and the partial discharge fixing seat A partial discharge assembly 23 is rotatably connected, and one end of the partial discharge assembly 23 is prov...

Embodiment 2

[0034] This embodiment is further optimized on the basis of Embodiment 1 as follows: the first drive unit includes a drive motor 5, a driving wheel 6, a driven shaft 8, a driven wheel 7, a timing belt 9 and a timing belt pressure block 10; 6 and the driven wheel 7 are respectively arranged on the left and right sides of the guide rail 2, the driving wheel 6 is connected to the drive shaft of the drive motor 5, the driven shaft 8 is connected to the lower end of the fixed plate 1, the driven wheel 7 is connected to the driven shaft 8 in rotation, the active The wheel 6 and the driven wheel 7 are connected to each other through a timing belt 9 , and the timing belt 9 and the sliding seat 4 are connected to each other through a timing belt pressing block 10 .

[0035] In this embodiment, the left and right movement of the sliding seat 4 is realized through the synchronous belt 9. The transmission of the synchronous belt 9 has the advantages of accurate transmission ratio, no slip,...

Embodiment 3

[0037] This embodiment is further optimized on the basis of embodiment 1 as follows: the left limit switch 13 and the right limit switch 14 are respectively arranged on the left and right sides of the lower end of the fixed plate 1 . Fixed plate 1 lower end is also provided with left limit block 11 and right limit block 12, and left limit block 11 and right limit block 12 are all positioned at the outside of left limit switch 13 and right limit switch 14.

[0038] After adopting this technical solution, when the driving motor 5 works, the driving shaft rotates through the synchronous belt 9 to drive the sliding seat 4 to slide left and right in the horizontal direction, and the left and right limit switches 13 and 14 are respectively arranged on the left and right sides of the fixed plate 1 On the outside of the left limit switch 13 and the right limit switch 14, a left limit block 11 and a right limit block 12 are respectively arranged. When the sliding seat 4 slides to the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com