Automatic sorting and packaging equipment

A technology of automatic sorting and equipment, applied in packaging and other directions, can solve the problems of easy collapse of color boxes, troublesome packaging, relying on manual transportation, etc., and achieve the effect of solving natural loosening, reducing labor intensity and novel overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

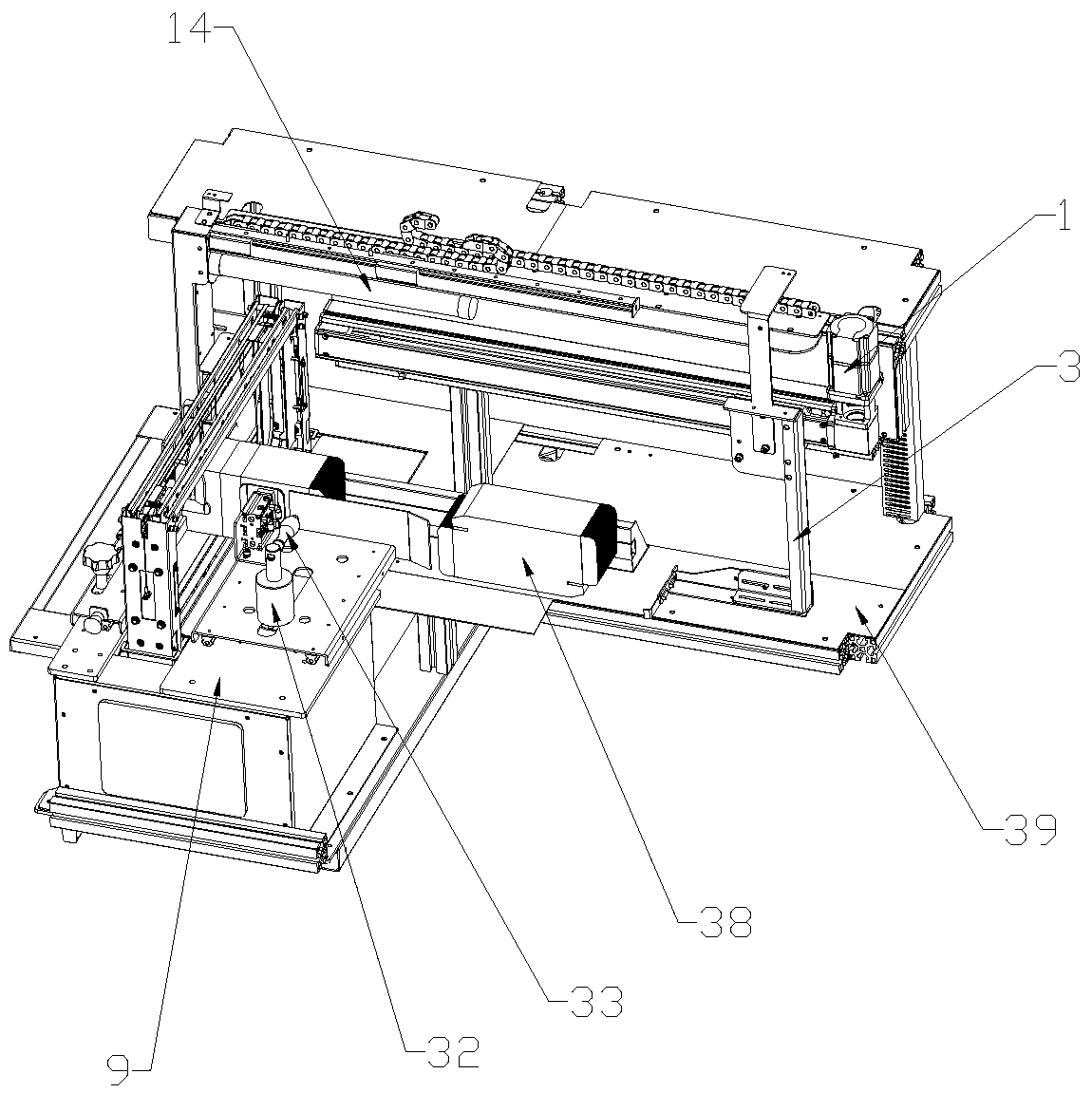

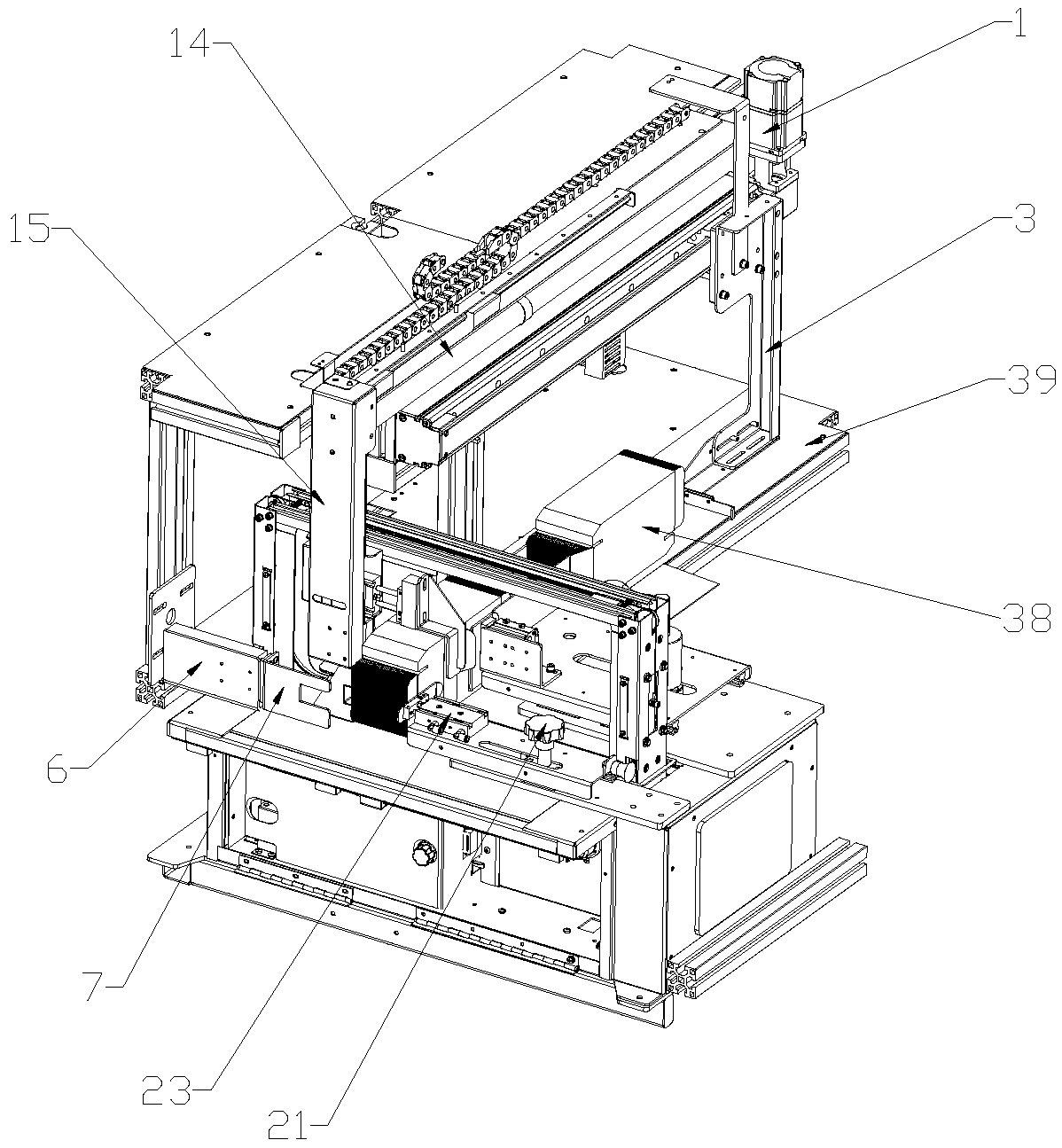

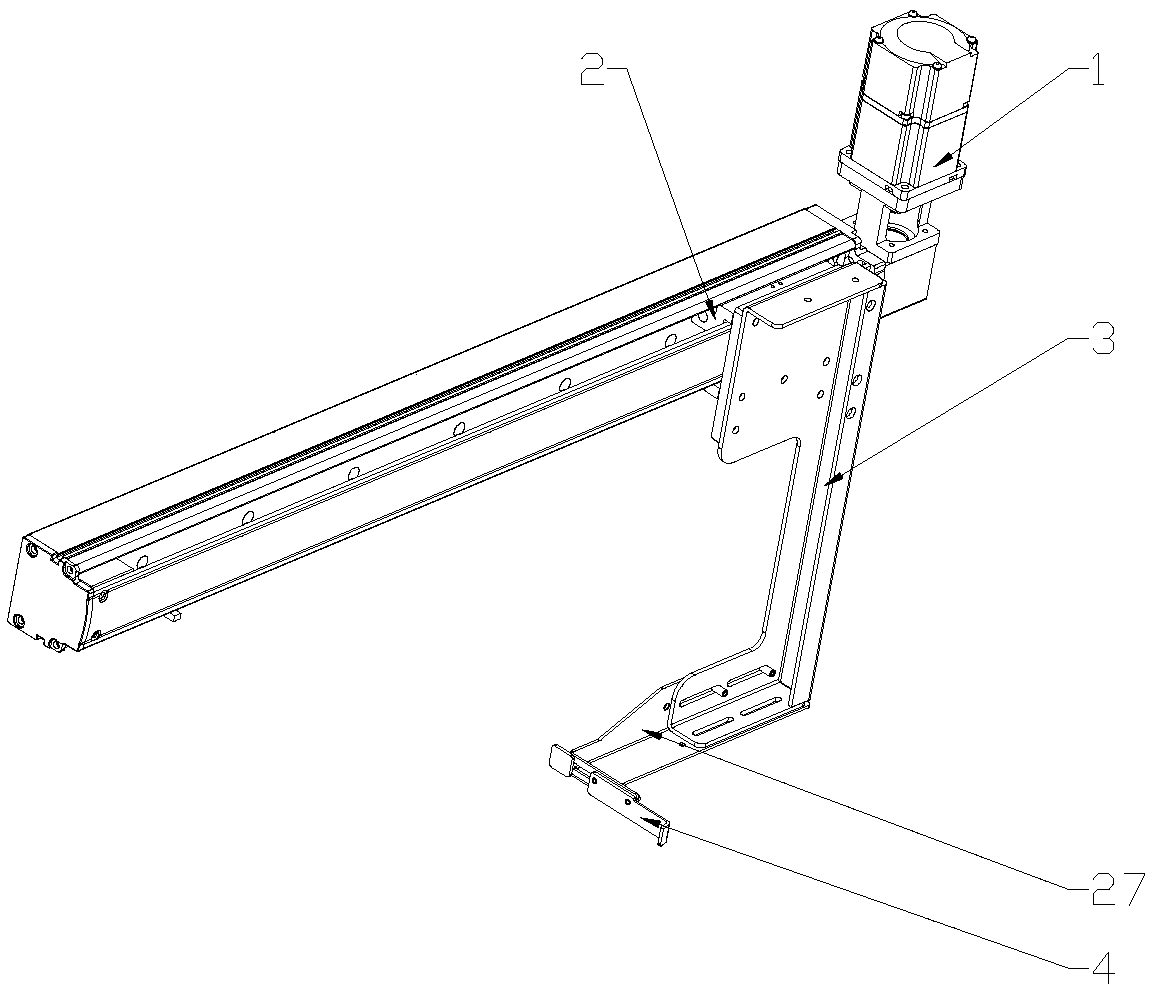

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] like Figure 1 to Figure 7 As shown, in this embodiment, a device for automatically sorting and packing includes a device support 39, a pushing device, a material blocking and aligning device, a material pressing device and a material pulling device; the pushing device includes a servo motion unit 1 , push group installation base 2, push material support 3 and push material plate 4, the servo motion unit 1 is installed on the equipment support 39, the push group installation base 2 is connected with the servo motion unit 1 through transmission, The push material support 3 is fixed on the push group mounting base 2, the push material plate 4 is located at the lower end of the push material support 3 and is fixedly connected with the push material support 3; The finishing and aligning device c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com