A Furnace Cover Inversion and Furnace Cover Installation Process

An installation process and furnace cover technology, which is applied in the field of industrial infrastructure and large-scale installation, can solve the problems of tight ground space, failure to perform normally, and need for rework, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with accompanying drawing, with regard to specific embodiment, this technology is further described:

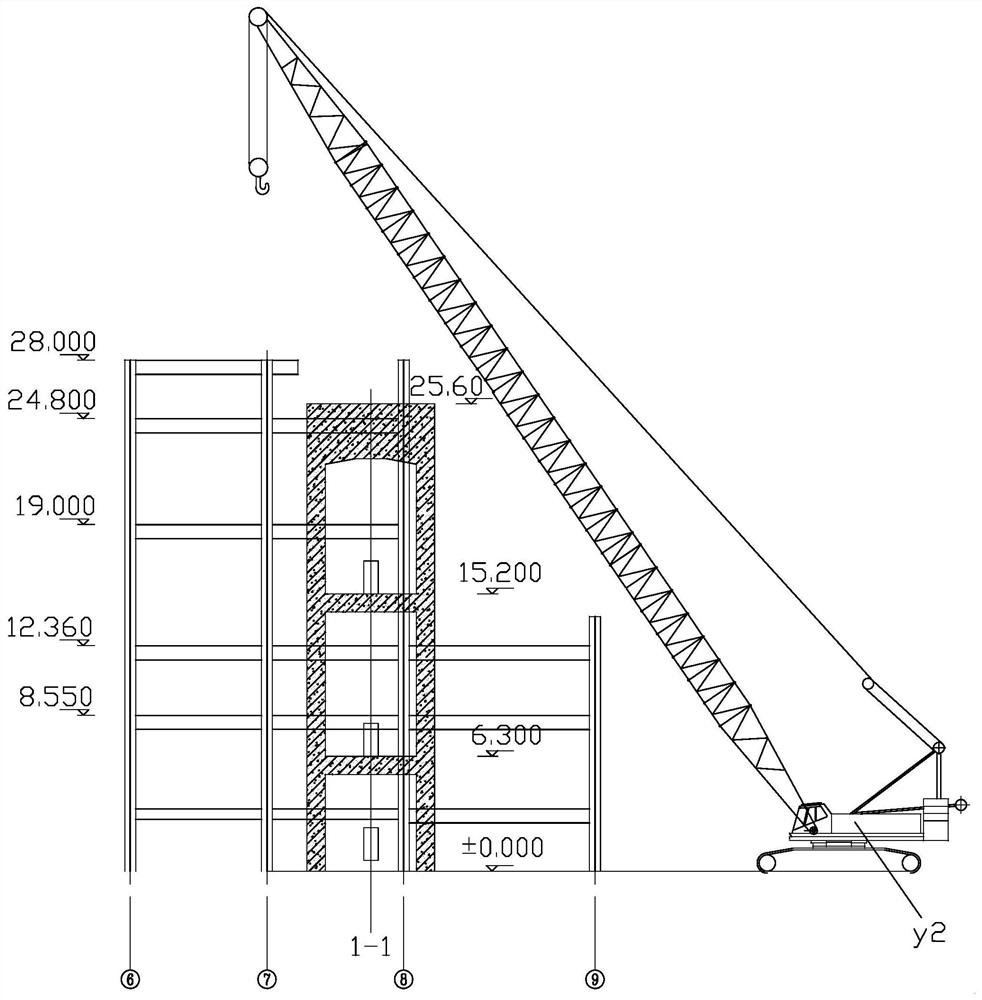

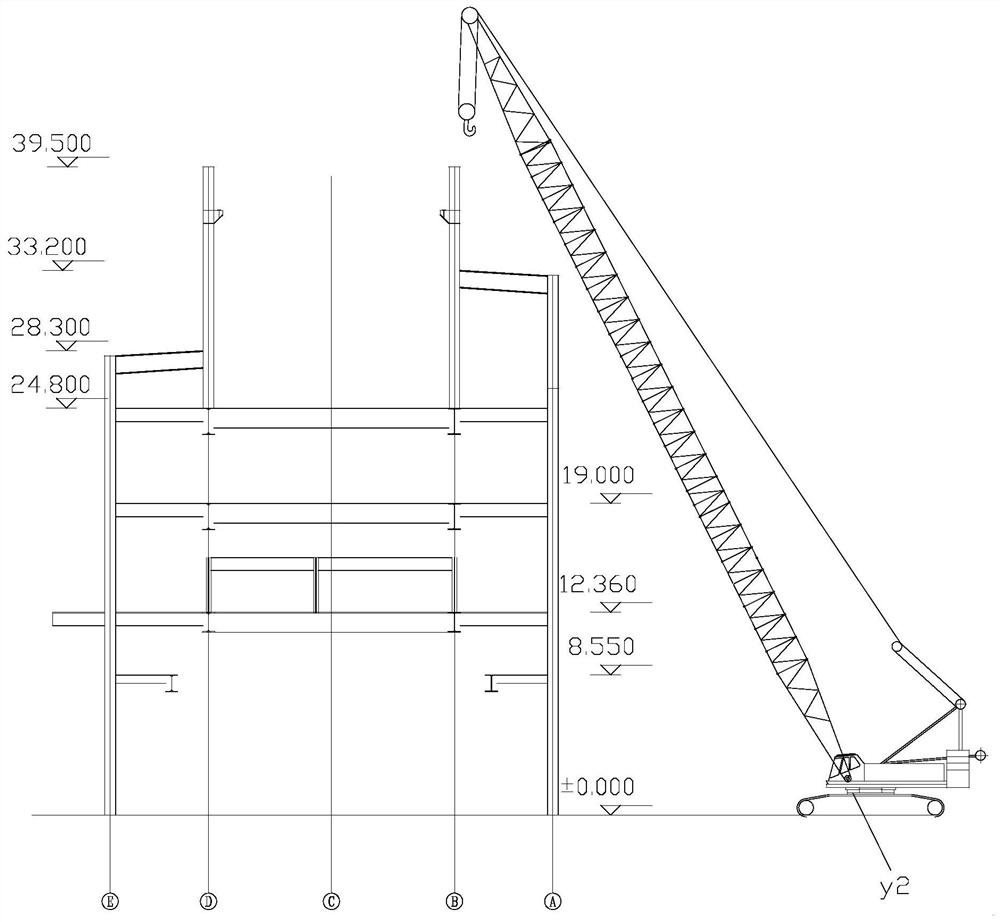

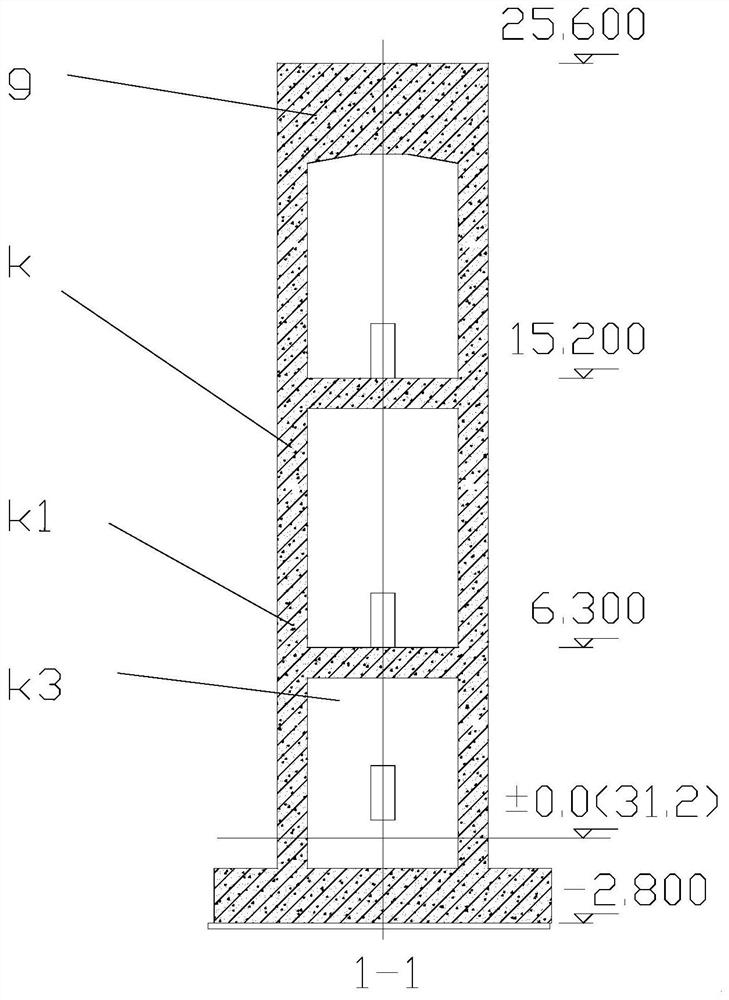

[0069] see Figure 6 , Figure 9 , Figure 10 , Figure 12-Figure 22 A furnace cover inversion and furnace cover installation process is shown, including an electric furnace workshop (also referred to as a workshop in this case) c formed by a steel structure c2, a roof and a defense system c3, and a furnace shell k that has been installed and in place, including The split furnace cover g4 of the peripheral section furnace cover g1, the middle section furnace cover g2 and the central section furnace cover g3; the flatbed truck used to transport the split furnace cover g4 to the on-site yard y1 for lifting and installing the split furnace The mobile hoisting equipment for the cover g4, the main hoisting system with the main hoisting machine and the main hoisting pulley block, and the auxiliary hoisting system with the auxiliary hoisting machine an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com