A manufacturing process control method for heavy parts of marine diesel engines based on digital twins

A technology for the manufacturing process and heavy parts, which is applied in the field of manufacturing process control of heavy parts of marine diesel engines based on digital twins, can solve the problems of complex shape and processing technology, high processing accuracy of critical parts, etc., so as to save manpower and material resources and optimize processing The effect of the parameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

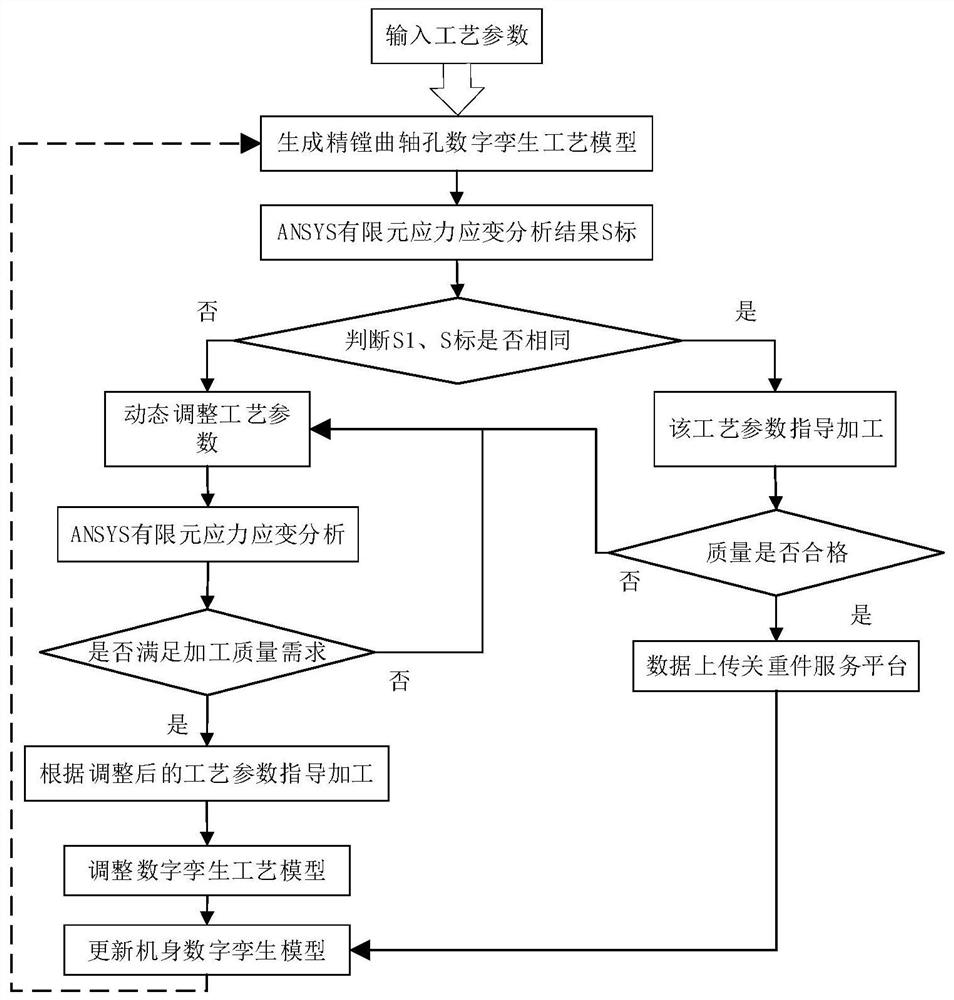

[0042]The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

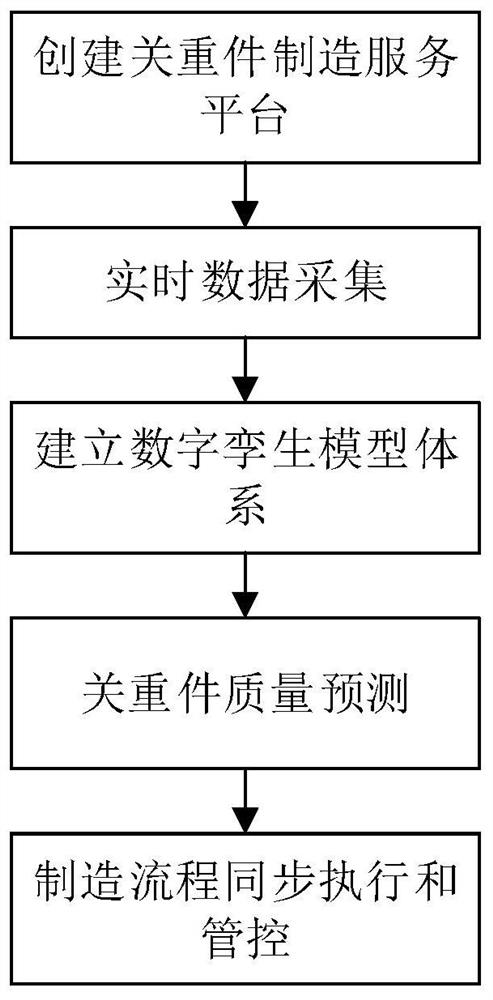

[0043]Such asfigure 1 Shown is a flowchart of the present invention. A method for controlling the manufacturing process of marine diesel engine heavy parts based on digital twin, including the following steps:

[0044](1) Create a key heavy parts manufacturing service platform: carry out digital modeling of the heavy parts manufacturing workshop of marine diesel engine, generate a digital simulation model of the manufacturing workshop in the computer virtual space, and form a one-to-one mapping with the physical objects in the workshop. Build a service platform for manufacturing key parts;

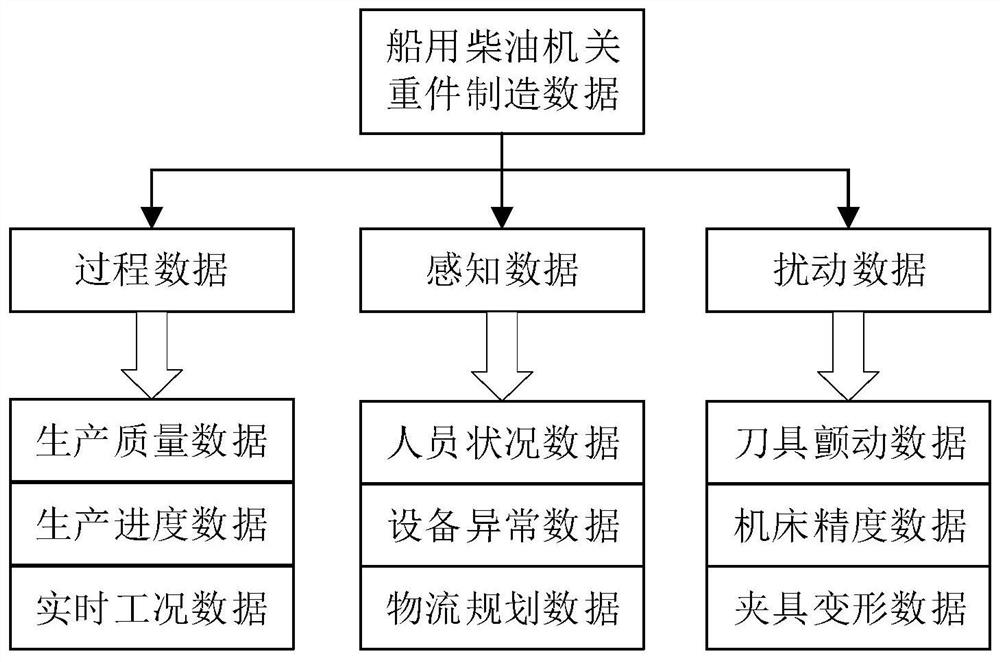

[0045](2) Real-time data collection: Real-time data collection is carried out on the ship diesel engine heavy parts workshop through sensors and radio frequency identification. The collected data includes process data, resource equipment data and disturbance data. Cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com