Elevation adjustable type steel dam gate device

An adjustable, steel dam technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve problems such as hydraulic transmission error, large error, door plate flip angle error, etc., to achieve accurate calibration, reduce flip errors, and reduce loads. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

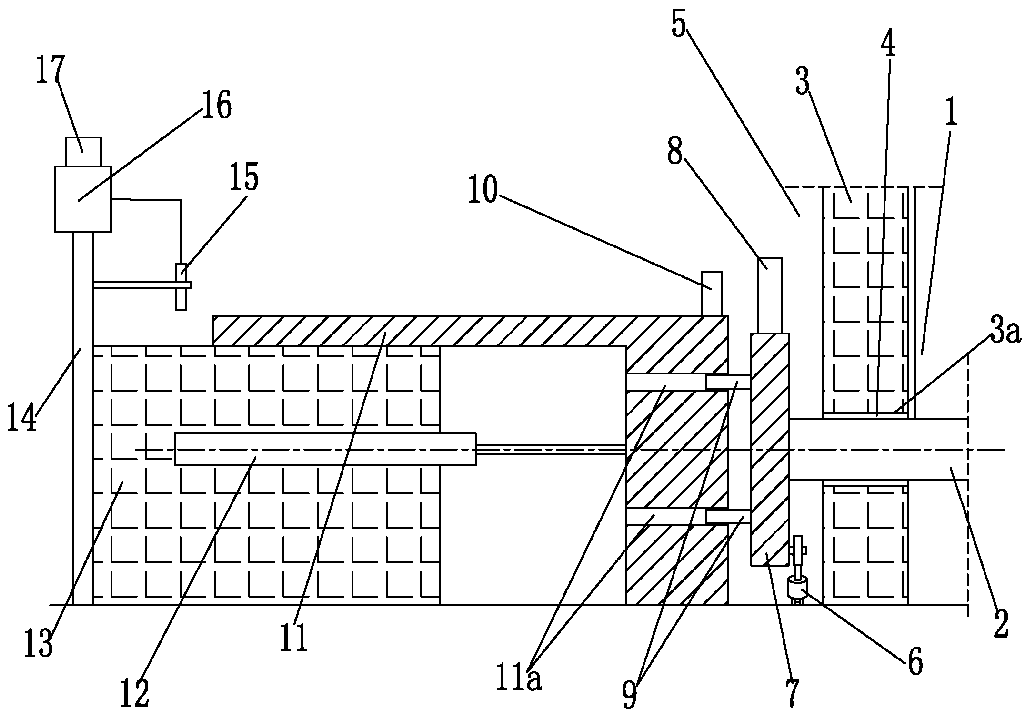

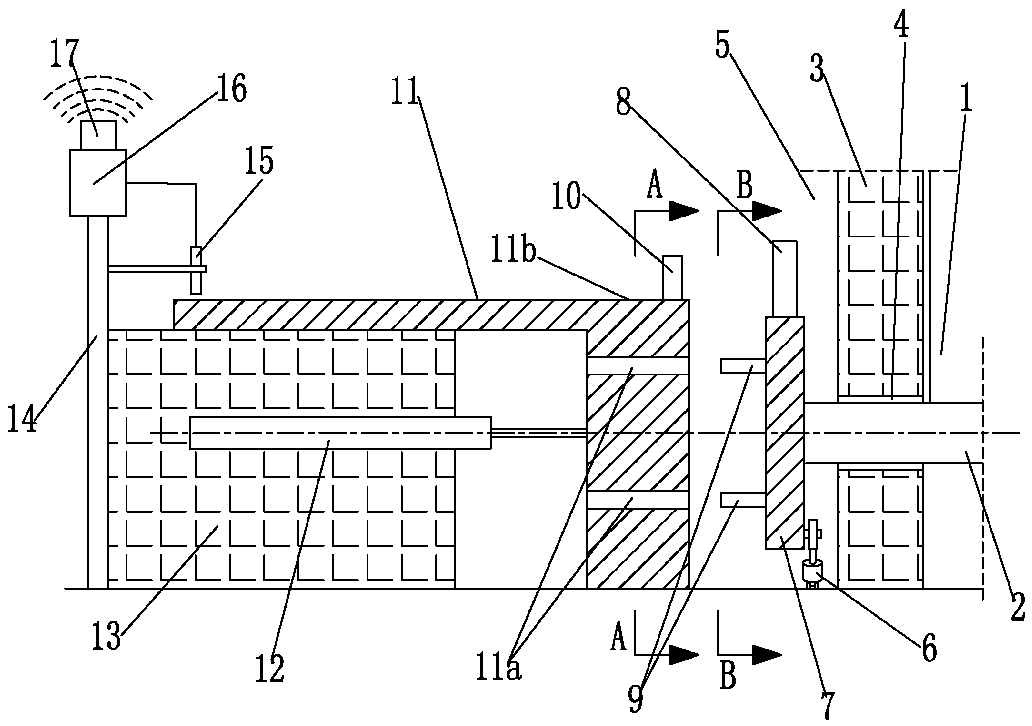

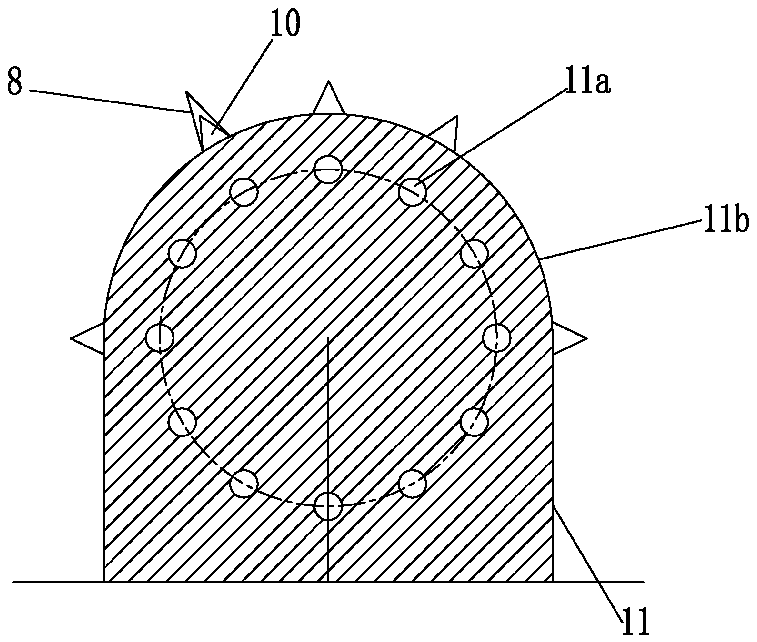

[0016] Such as Figure 1-4 As shown, an elevation-angle-adjustable steel dam gate device includes a door panel 1, a bottom turning shaft 2, a wall panel 3, and a control room 5. The bottom turning shaft 2 is arranged horizontally, and the door panel 1 is fixed on the outer peripheral side of the bottom turning shaft 2. The wall panel 3 is provided with a pair corresponding to the positions of the two shaft ends of the bottom turning shaft 2, the wall panel 3 is provided with a penetration hole 3a that can accommodate the bottom turning shaft 2 passing through, and the control room 5 corresponds to the position of the bottom turning shaft 2 shaft ends and is located on the wall panel 3, the shaft end of the bottom turning shaft 2 passes through the penetrating hole 3a of the wallboard 3 and extends into the control room 5, and a liquid is filled between the outer peripheral side of the bottom turning shaft 2 and the penetrating hole 3a of the wallboard 3 The water-stop seal 4 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com