Block stator press-fitting shell device

A stator and shell technology, which is applied in the field of sub-block stator press-fit shell devices and press-fit devices, can solve problems such as unsatisfactory stator roundness, poor motor assembly quality, and large interference requirements, and achieve assembly quality Good, high production efficiency, uniform interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is based on Figure 1 to Figure 12 The specific embodiment of the present invention is further described:

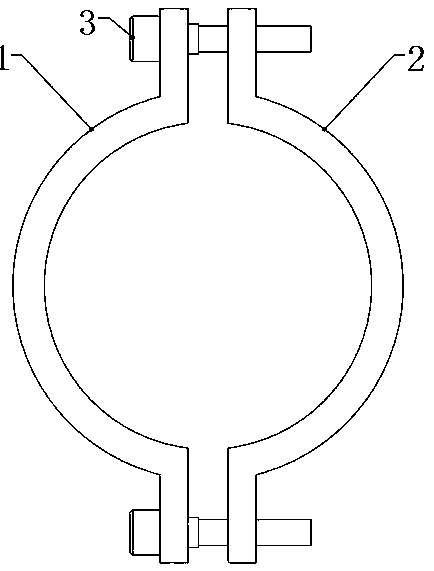

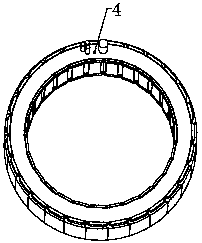

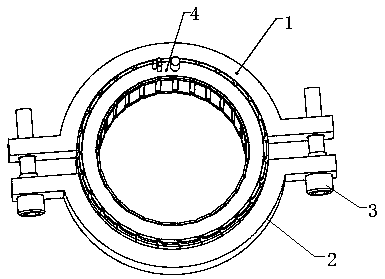

[0030] A segmented stator press-fit housing device, including a clamping ring (structure such as figure 1 ), upper template 5 (structure such as Figure 4 ), middle template 9 (structure such as Figure 5 , the middle template 9 has the same structure as the lower template 23), the lower template 23 (structure such as Figure 5 ), guide post 16 (structure such as Figure 9 ), guide sleeve 17 (structure such as Figure 9 ), the upper pressure head 13 (structure such as Image 6 ), the lower pressure head 15 (structure such as Figure 7 ), limit block 20 (structure such as Figure 9 ), bolt 18 (structure such as Figure 9 ) and nut 19 (constructed as Figure 9 ). see figure 2 , multiple segmented stators can be spliced together to form a similar circular stator 4, see image 3 The clamping ring is sleeved on the outside of the spliced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com