Threading and drafting device for doup harnesses for weaving leno brocade by using rapier loom

A technology of leno fabric and twisted healds, which is applied in auxiliary equipment for weaving, textiles, textiles and papermaking, etc. It can solve the problem of reducing the additional tension in the twisting process of the twisted warp, reducing the rate of warp yarn breakage, and reducing the depth of the harness, etc. problem, to achieve the effect of simplifying the twisting principle, excellent jacquard leno fabric, and adding stable devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

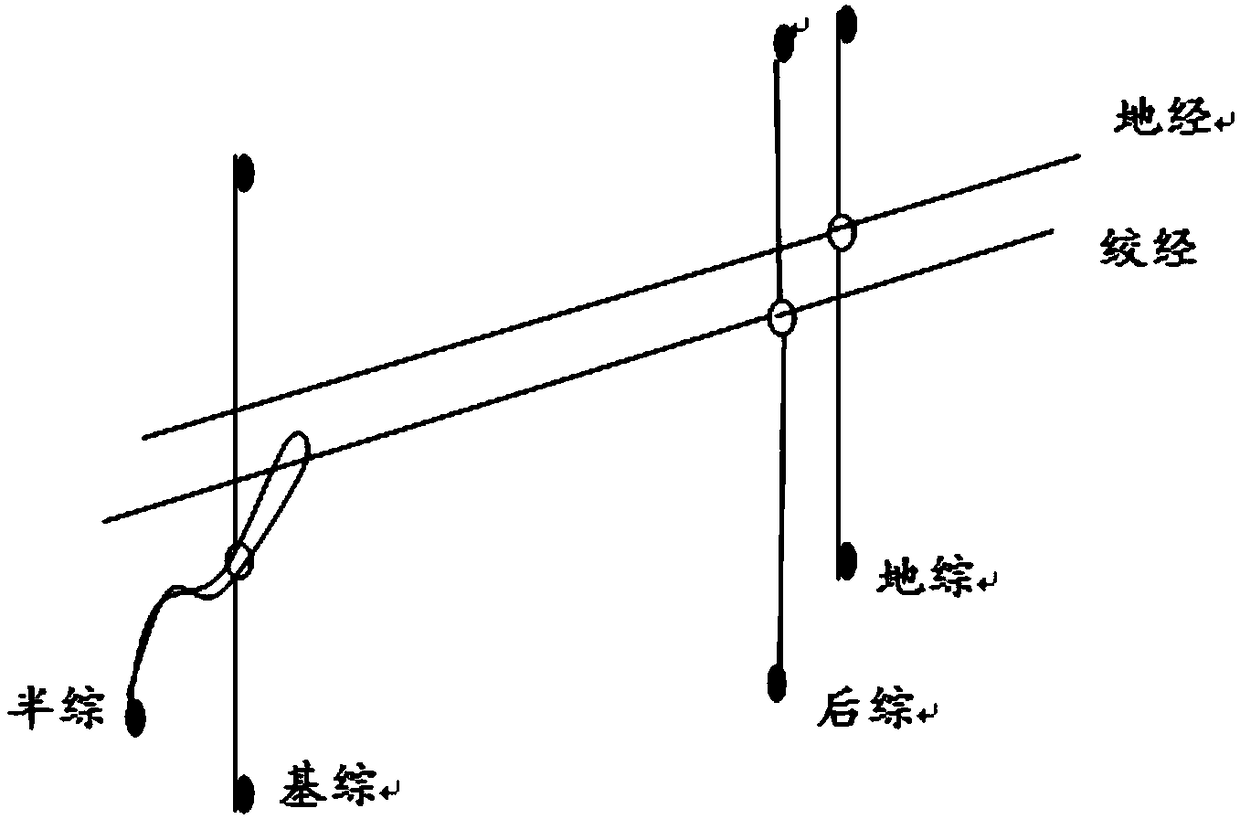

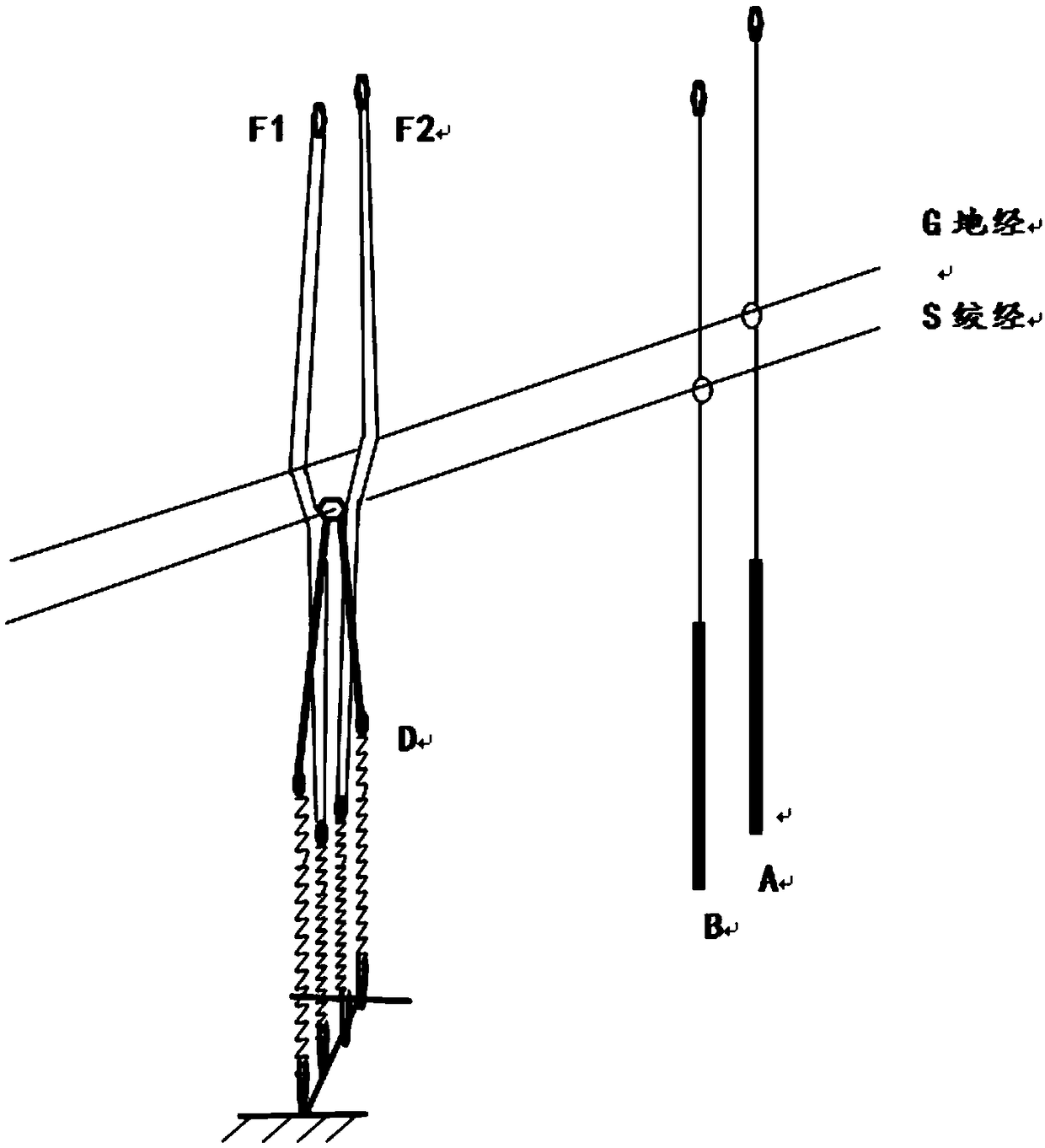

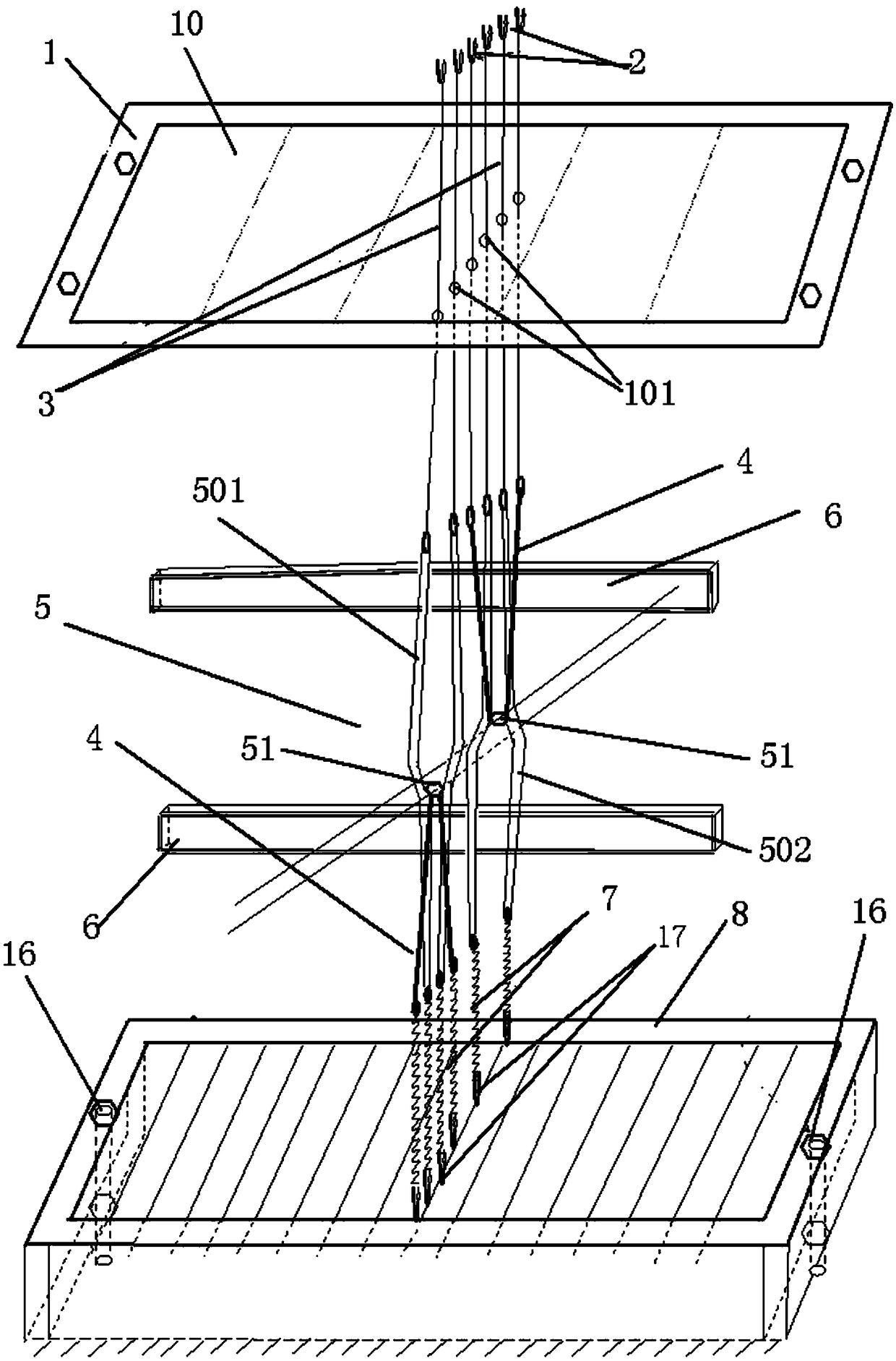

[0023] Embodiment 1: refer to Figure 3-5 . A twisted heddle hanging device for weaving jacquard leno fabrics on a rapier loom, comprising a rapier eye plate support frame 1, a column plate 10, a faucet handle hook 2, a hanging wire 3, and a metal half-heald small fork 4. Twisted heald group 5, positioning plate 6, several returning heald springs 7, hanging heddle support frame 8, rapier eye plate support frame 1 is provided with column plate 10, and several harnesses are evenly distributed on the column plate 10 Hole 101, a number of faucet hooks 2 are distributed above the column plate 10, a hanging heddle support chassis 8 is arranged below the column plate 10, and several Row heald groups 5, each row heald group 5 has a number of twist healds 50 arranged from front to back, each twist heald 50 is in the shape of an "X", with heald eyes 51 arranged at the intersection, and the upper part is used as the upper twist heddle 52. Its lower part is used as the lower twisted hed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com