Rare earth functional ceramic pigment equipment

A technology of functional ceramics and pigments, applied in mixers, mixers with rotating stirring devices, shaking/oscillating/vibrating mixers, etc., can solve the problems of low mixing efficiency and cumbersome operation steps, and reduce work The effect of time length, solving the insufficiency of mixing efficiency, and improving the working efficiency of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

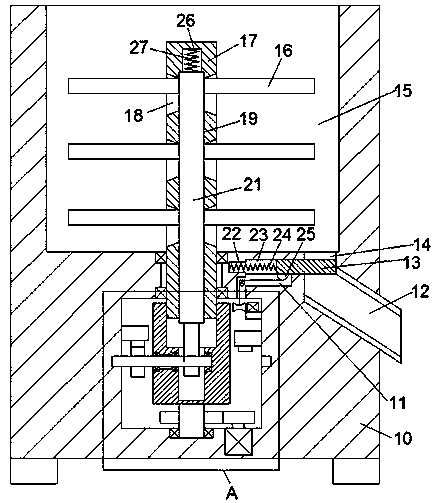

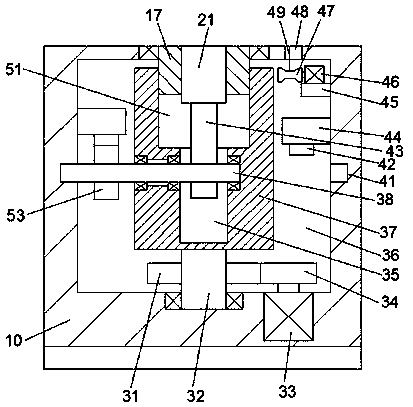

[0011] Combine below Figure 1-2 The present invention will be described in detail.

[0012] refer to Figure 1-2 , a kind of rare earth functional ceramic pigment equipment according to an embodiment of the present invention, including a frame 10, a stirring chamber 15 is arranged in the top end surface of the frame 10, and a stirring chamber 15 is arranged on the lower side of the stirring chamber 15 in the frame 10 An arc-shaped drive chamber 36 is provided, and a stirring shaft 17 is installed in rotation between the arc-shaped driving chamber 36 and the stirring chamber 15. The stirring shaft 17 extends into the stirring chamber 15 and extends up and down in the bottom end surface. A swing groove 19 is provided, and a swing arm 21 is installed in the swing groove 19, and a plurality of sets of side cavities 18 are arranged symmetrically on the left and right sides of the swing groove 19, and a mixing paddle is installed in the side cavity 18 in a sliding fit. 16. The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com