Sintering and curing material for curing and connecting prebaked anode carbon block

A prebaked anode and solidified material technology, applied in the field of aluminum electrolysis, can solve the problems of loss of adhesion and grip, hot melting, volatilization, polycondensation, anode carbon block drop, etc., to increase the emission of harmful substances and reduce production costs , reduce the effect of residual poles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

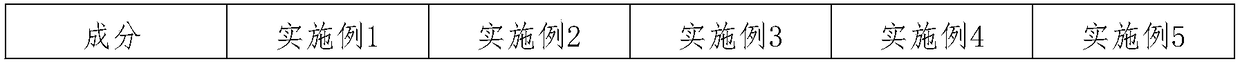

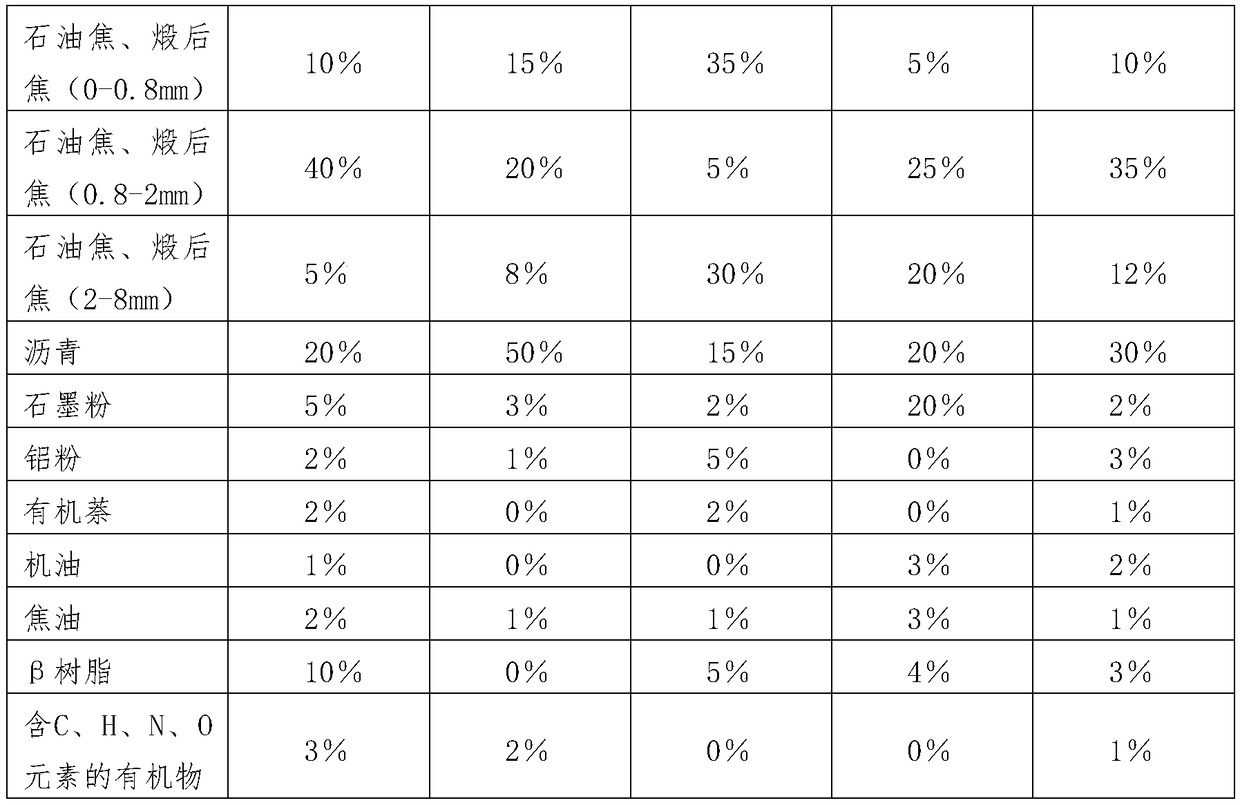

Method used

Image

Examples

Embodiment 6

[0061] An application of a sintered solidified material in the field of electrolytic aluminum. The sintered solidified material is applied to the continuation of the aluminum electrolytic prebaked anode carbon block through softening and sintering. The sintered solidified material is made into a thin sheet through pretreatment, and it is to be placed in the electrolytic cell. When the online anode is consumed to the point that a new anode needs to be added, the thin plate-shaped sintered and solidified material is sandwiched between two carbon blocks when the anode is connected. The sintered and solidified material in the shape of a thin sheet is softened first, and then sintered and solidified until the two anode carbon blocks are bonded into one.

Embodiment 7

[0063] An application of a sintered solidified material in the field of electrolytic aluminum. The sintered solidified material is applied to the continuation of aluminum electrolytic prebaked anode carbon blocks through softening and sintering, and the sintered solidified material is made into a pasty sintered solidified material through pretreatment, and then Spread it evenly on the bottom of the new anode carbon block, and form a plate-shaped solid layer with a thickness of >1mm after solidification. When the online anode in the electrolytic cell is consumed to the point where a new anode needs to be added, the new anode with a sintered and solidified plate-shaped solid layer on the bottom surface Directly press and place on the anode of the original tank. In the temperature environment of 100°C to 900°C in the electrolytic cell, the plate-shaped solid layer of the sintered solidified material is softened first, and then sintered and solidified until the two anode carbon bloc...

Embodiment 8

[0065] An application of a sintered solidified material in the field of electrolytic aluminum. The sintered solidified material is applied to the continuation of aluminum electrolytic prebaked anode carbon blocks through softening and sintering, and the sintered solidified material is made into a powder-like sintered solidified material through pretreatment. When the online anode in the electrolytic cell is consumed to the point where a new anode needs to be added, evenly sprinkle the powdery sintered and solidified material on the upper surface of the original anode in the cell, and then press the new anode directly on the anode in the original cell, between the two anodes Form a layer of sintered solidified material powder layer with a thickness > 1mm. In the temperature environment of 100°C to 900°C in the electrolytic cell, the sintered solidified material powder layer is first melted and softened, and then sintered and solidified until the two anode carbon blocks are bonded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com