Firing pin type firing mechanism achieving clear sensing function and ready-to-fire state indicating function

A firing mechanism and firing pin technology, which is applied to firing/trigger mechanisms, weapon accessories, offensive equipment, etc., can solve the problems of no indication features and inconspicuous perceptible features of firing pin pistols to be fired, and achieve a simple assembly process. , a small number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

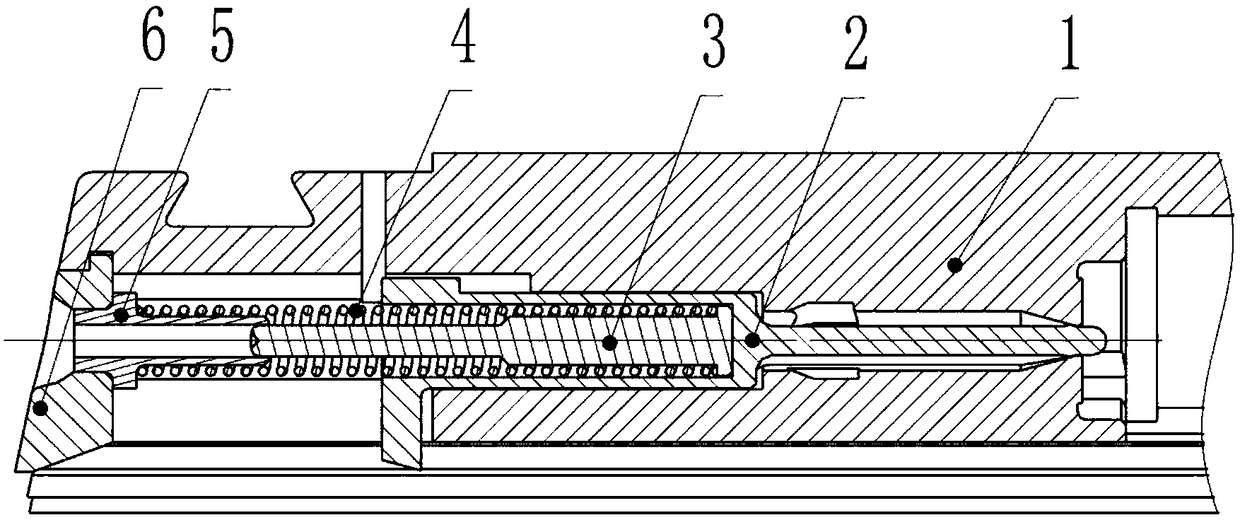

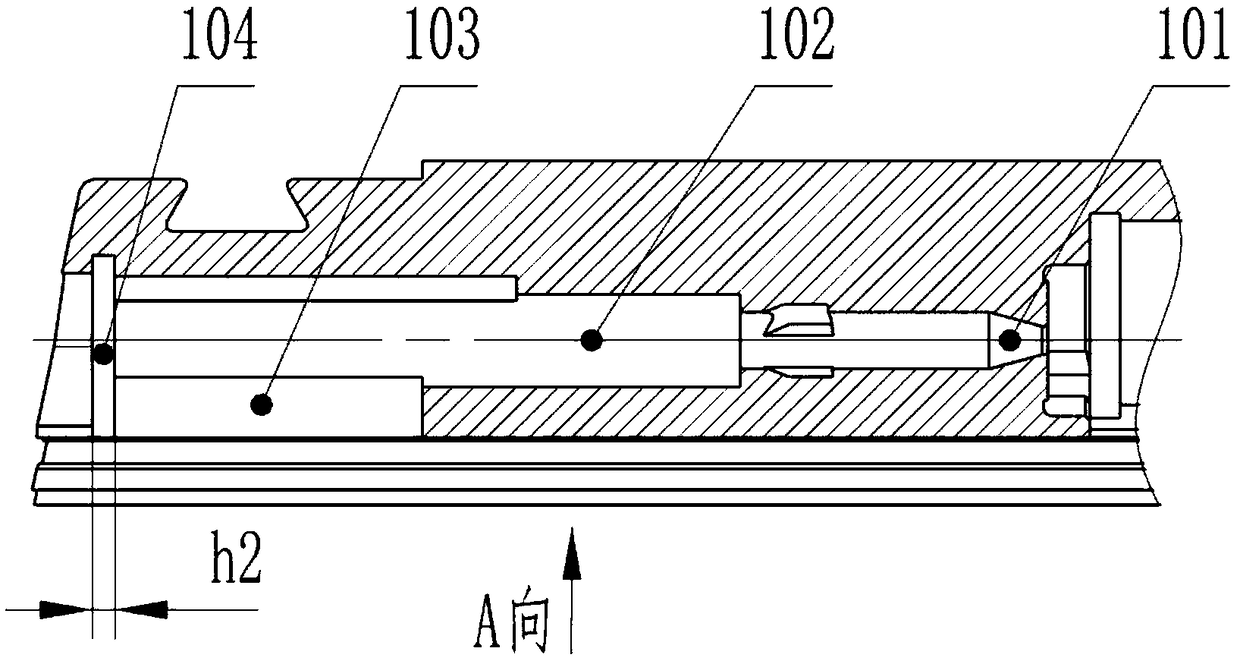

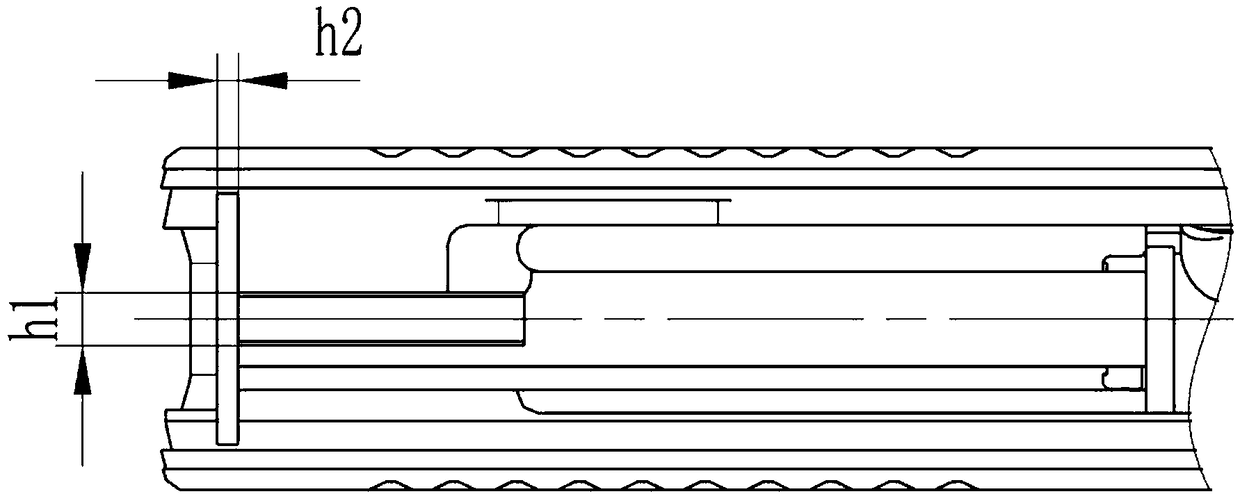

[0030] Such as Figure 1-Figure 13 As shown, an embodiment of a firing pin firing mechanism with a clearly perceivable ready-to-fire indication function includes a bolt 1, and a firing pin hole 102 is arranged inside the bolt 1, and the firing pin hole 102 includes sequentially from front to back. The setting cone hole 101 before the firing pin, the relief slot hole 103 for the firing pin tooth and the slot hole 104 of the bolt baffle, also include the firing pin 2 which is matched with the positioning cone hole 101 before the firing pin, and is installed on the bolt baffle. The trigger baffle plate 6 in the slot hole 104, the rear end of the firing pin 2 is provided with a firing pin spring container spring hole 202, and the firing pin spring container spring hole 202 is provided with a firing pin spring guide rod 3, which is sleeved on the firin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com