Intelligent warehousing robot and working method thereof

A technology of intelligent warehousing and robots, applied in the field of intelligent warehousing, can solve the problems of low efficiency of picking goods, high performance requirements, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

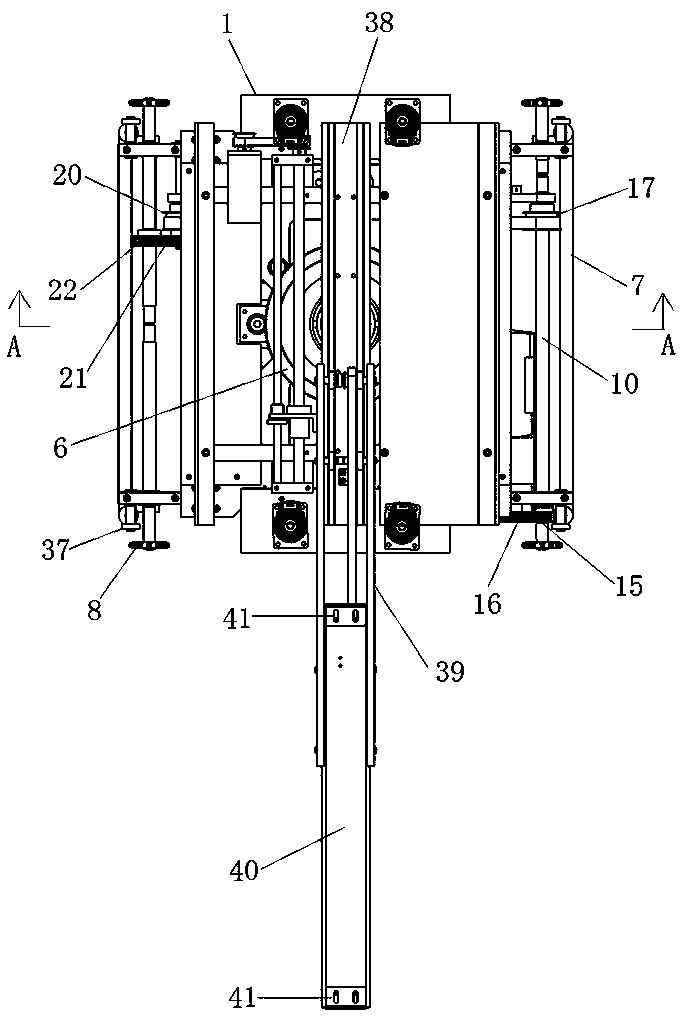

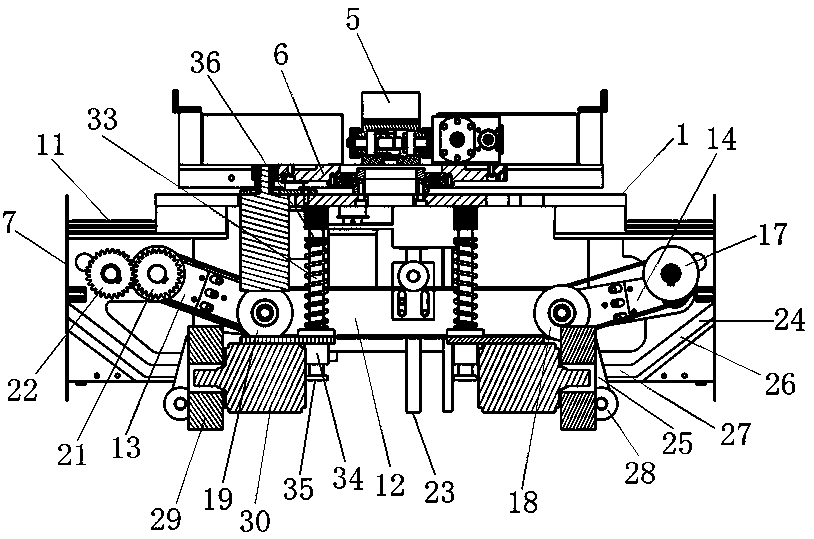

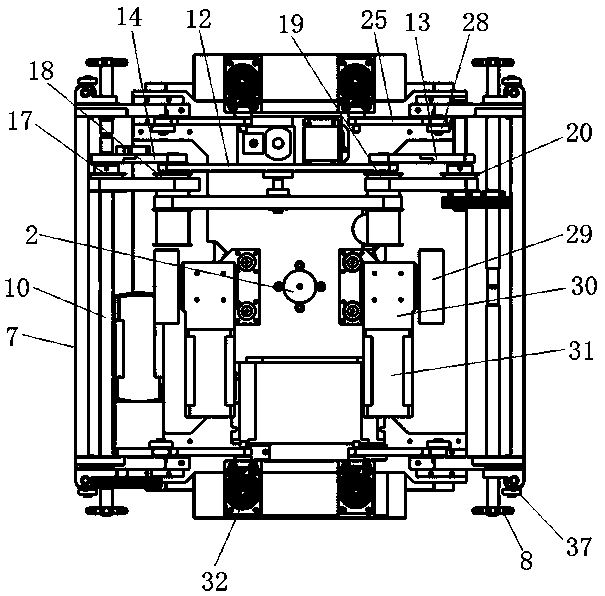

[0048] Embodiment: an intelligent storage robot of this embodiment, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a base 1. The bottom of the base 1 is provided with a camera 2 and a moving mechanism 3, the left and right sides of the base 1 are provided with shelf climbing devices, and the base 1 is provided with a telescopic mechanism 4 that drives the shelf climbing device to expand / retract. 1 The top is equipped with a robotic arm 5 for grabbing items and a rotating mechanism 6 that drives the robotic arm 5 to rotate. The shelf climbing device includes a bracket 7, a sprocket 8 located at the front and rear ends of the bracket 7, and a driving mechanism 9 that drives the sprocket 8 to rotate. The base 1 is also provided with a controller 42 and a wireless communication module 49. The controller 42 is electrically connected to the camera 2, the moving mechanism 3, the telescopic mechanism 4, the mechanical arm 5, the rotating mechanism 6, the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com