Electrical connector

A technology of electrical connectors and connecting parts, applied in the direction of connection, two-part connection device, circuit, etc., can solve the problems of cross-talk interference and affect the high-frequency performance of electrical connectors, and achieve the effect of reducing cross-talk interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

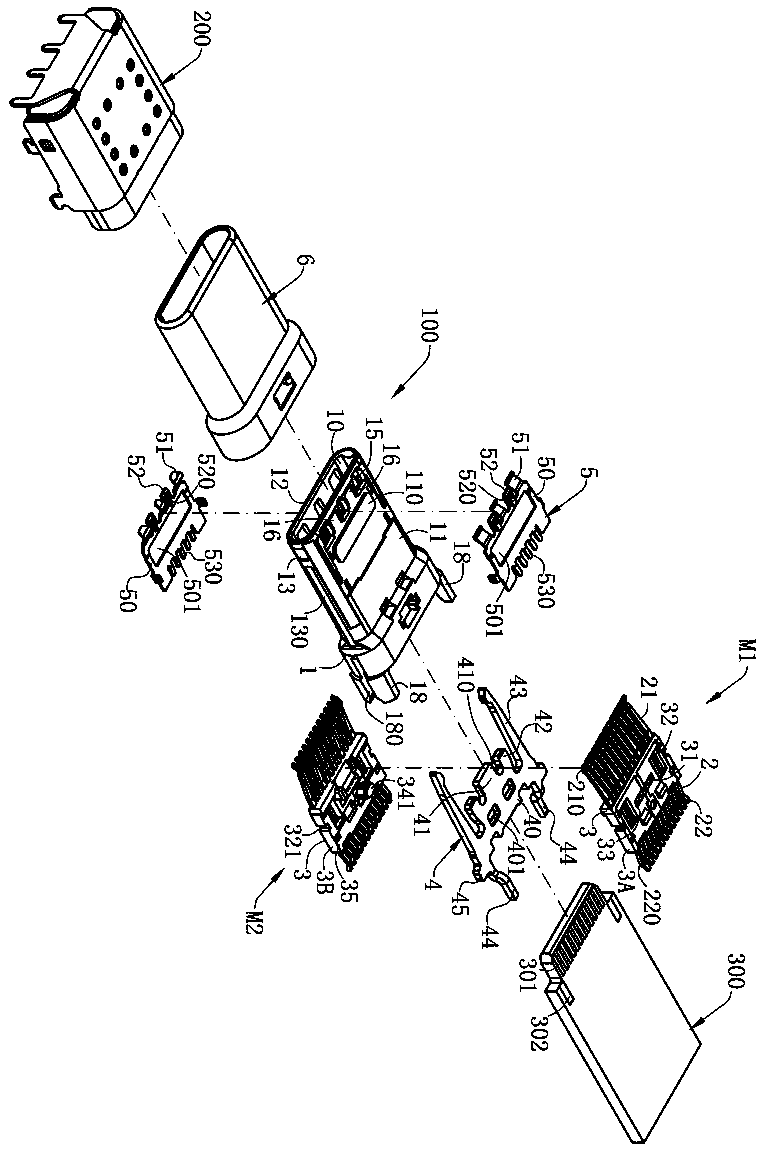

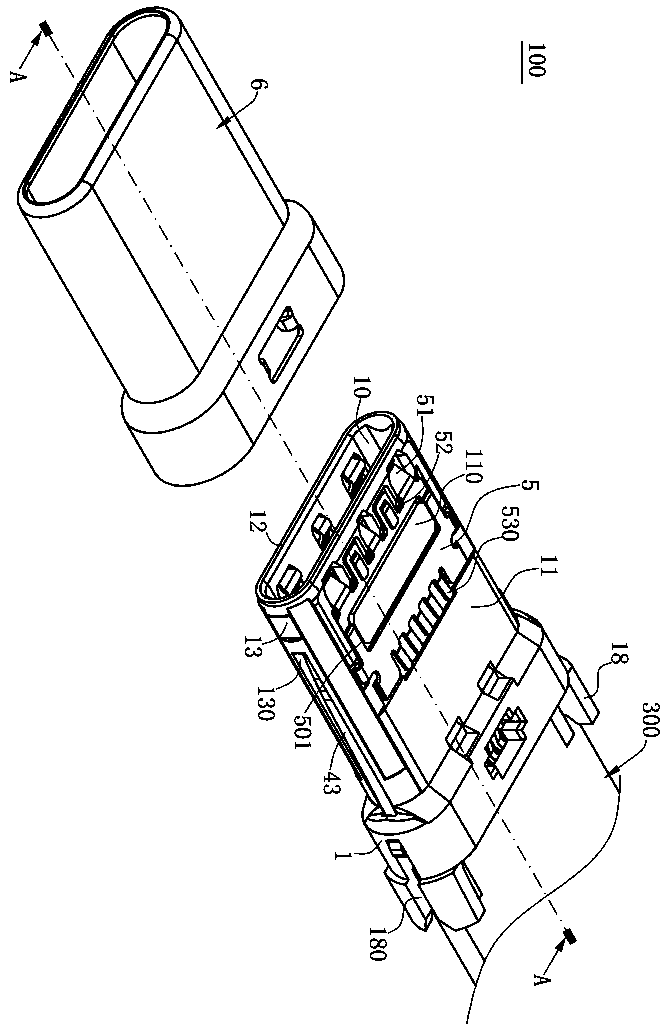

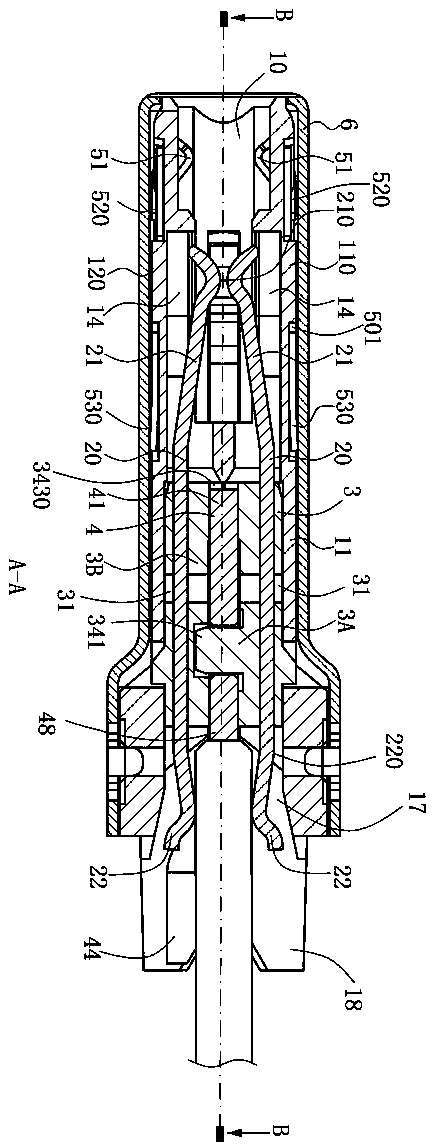

[0038] see figure 1 , figure 2 with image 3 , this is an electrical connector 100 of the embodiment of the present invention, the electrical connector 100 of this embodiment is a TYPE C plug connector, the electrical connector 100 is docked with a socket connector 200 forward, and installed backward on a circuit board 300 . The electrical connector 100 includes an insulating body 1, and the insulating body 1 contains a first terminal module M1, a second terminal module M2 and a shielding sheet 4, and the shielding sheet 4 is placed on the first terminal module M1. and the second terminal module M2. The two ground plates 5 are 180° symmetrical up and down, covering the upper and lower surfaces of the insulating body 1 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com