Double guiding rod pushing type rotary grooving machine

A double-guide, push-type technology, which is applied in the field of pipe fitting end processing, can solve the problems that the hydraulic mechanism cannot meet the size requirements, the force of the mechanism is unbalanced, and the mechanism is prone to vibration, etc., and achieve high push transmission efficiency and deep dimension Accurate and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

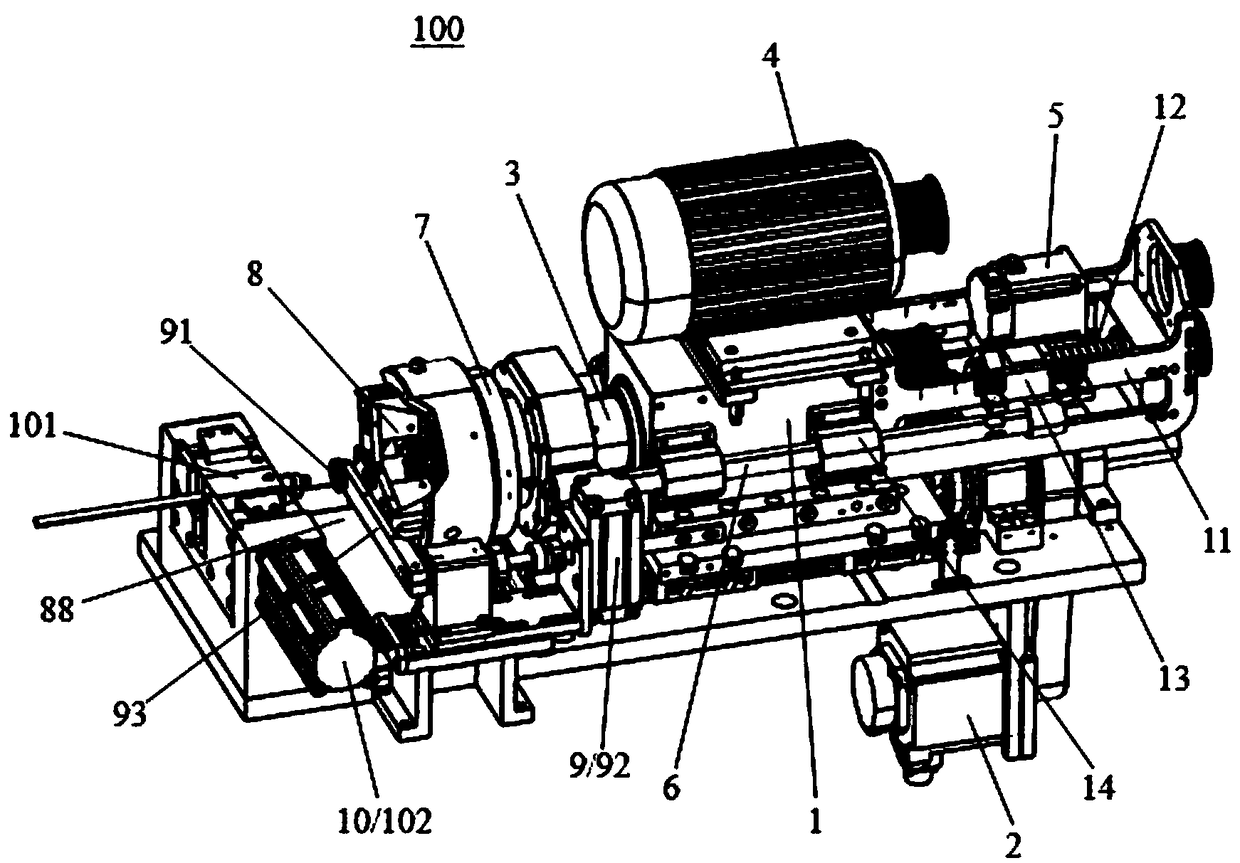

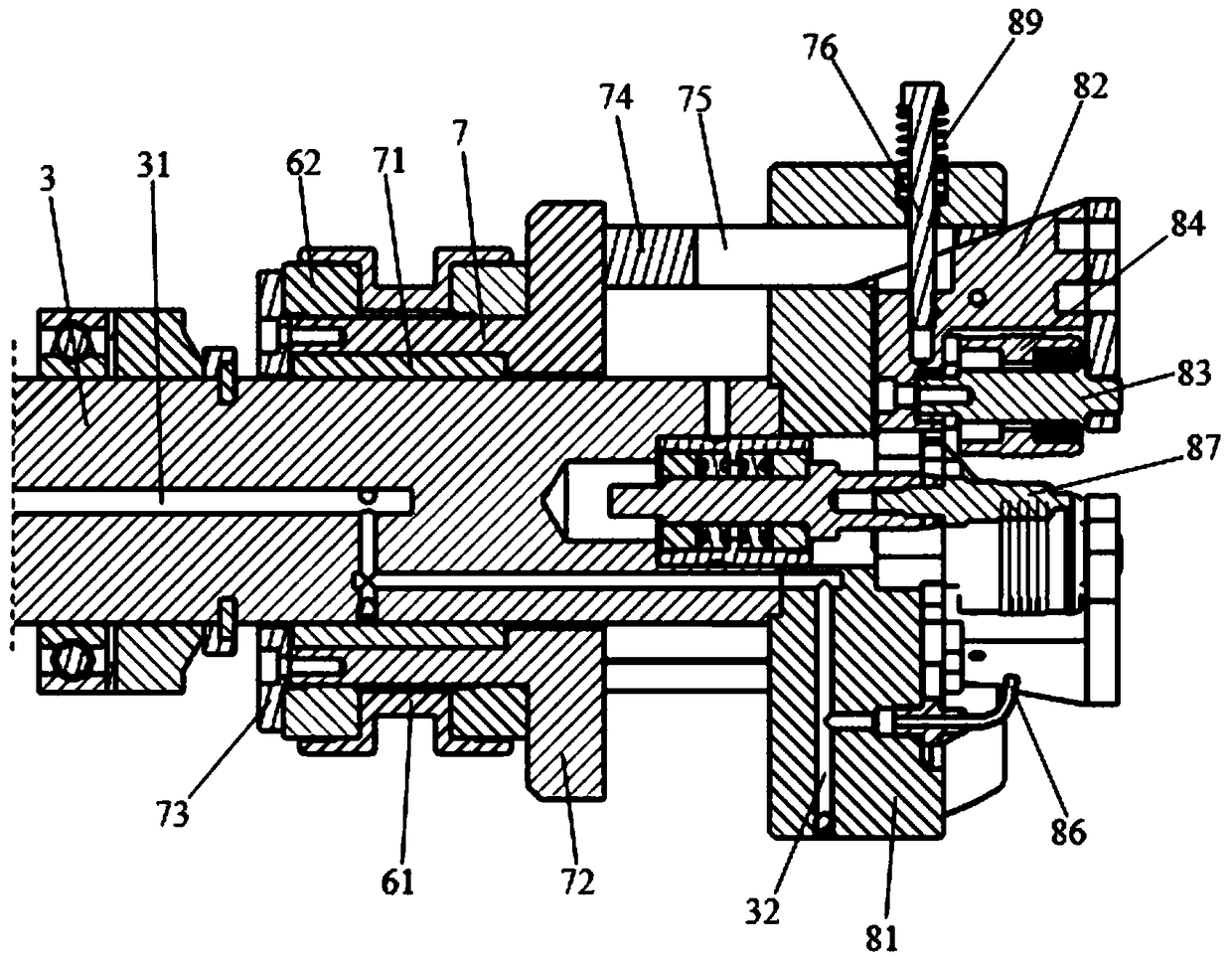

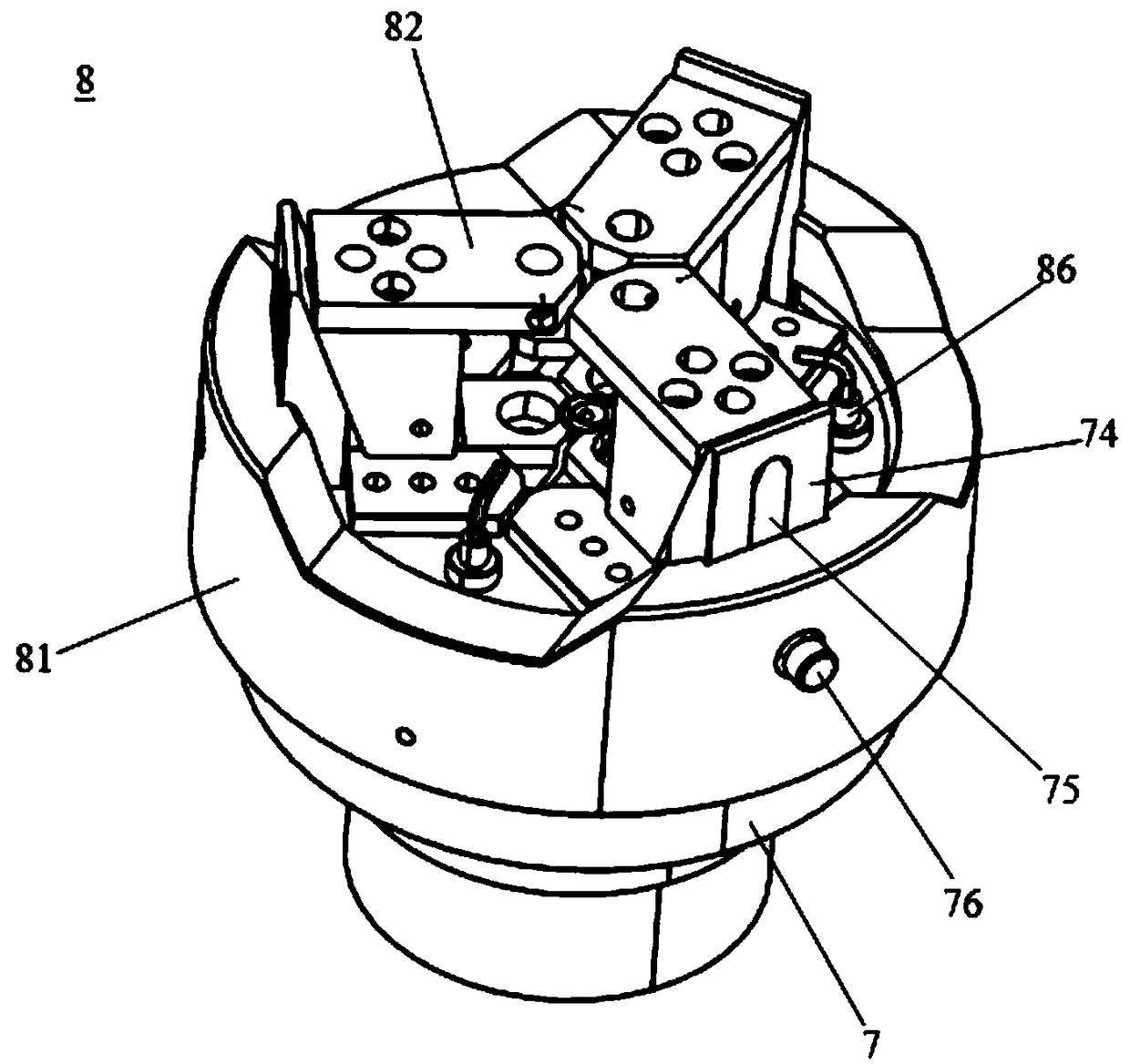

[0024] Please refer to Figure 1-Figure 4 , the present embodiment is a double-guide push-type slotting machine 100, which includes a main shaft rotation support base 1, a first driving member 2 for driving the main shaft rotation support base 1 to move left and right, a main shaft 3 arranged on the main shaft rotation support base 1, The second drive member 4 that drives the main shaft 3 to rotate, the third drive member 5 fixed on the main shaft rotation support base 1, the double drive parts that are driven by the third drive member 5 to move left and right and symmetrically distributed on both sides of the main shaft rotation support base 1 The guide rod 6, driven by the double guide rods 6, moves axially relative to the main shaft 3 and rotates synchronously with the main shaft 3. The rotating propulsion ring 7 is arranged at the end of the main shaft 3 and is driven by the rotating propulsion ring 7 to move closer to the axis center of the main shaft 3. A rotary groove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com