Depth gauge for arc surface in hole

A technology of depth sounder and inner arc, applied in the direction of mechanical depth measurement, etc., can solve the problems of affecting parts processing, inaccurate depth dimension, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

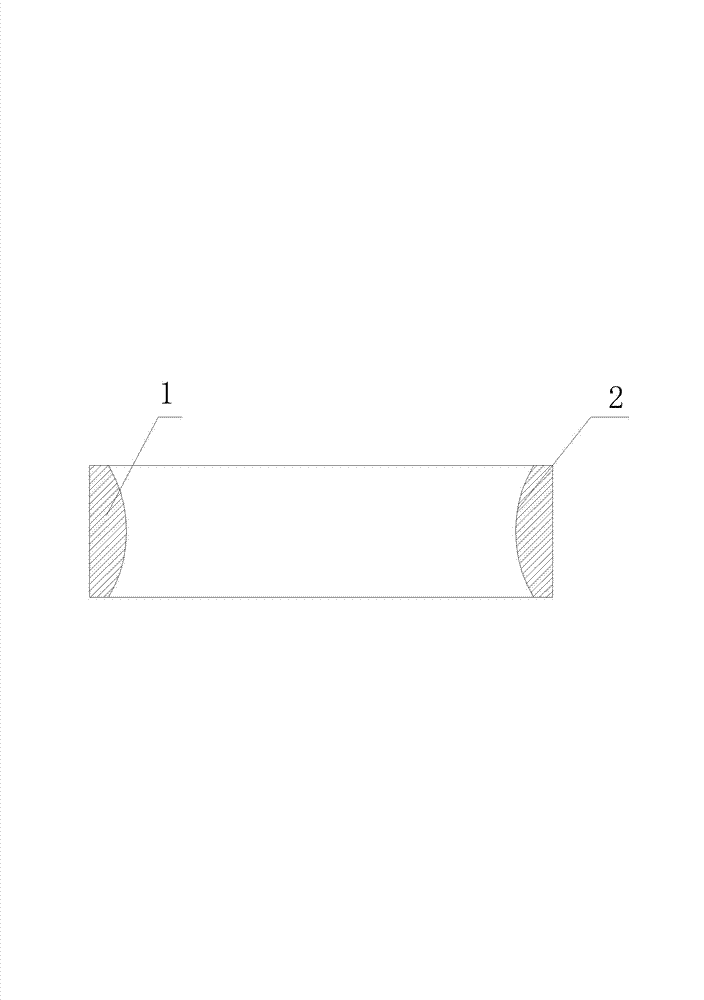

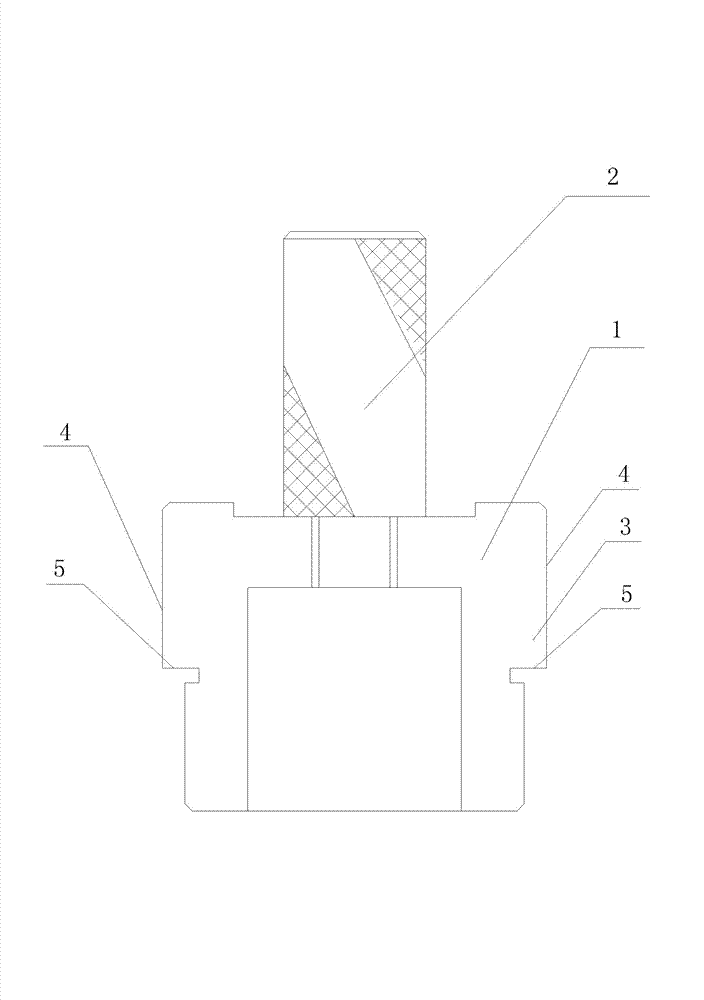

[0008] see figure 2 , An arc surface depth sounding gauge in a hole, comprising a sounding gauge body 1, a handle 2 is arranged on the sounding gauge body 1, and the side surface 4 and the bottom end surface 5 of the measuring end 3 of the sounding gauge body 1 are at right angles. . The measuring end 3 is made into a right-angle structure with deburring and no chamfering. According to the size setting of the measuring end 3, the depth from any inner diameter in the arc surface of the hole to the reference surface can be measured simply and conveniently, and the depth dimension is accurate. It provides a guarantee for the processing of parts matching the holes, and at the same time greatly improves the inspection efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com