Depth gauge for multiple oil grooves in hole

A technology of depth gauge and oil tank, which is applied in the field of measurement and inspection tools, can solve the problems of cumbersome measurement process, affecting the processing of parts, and inaccurate depth of oil tank, and achieve the effect of improving detection efficiency and accurate depth size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

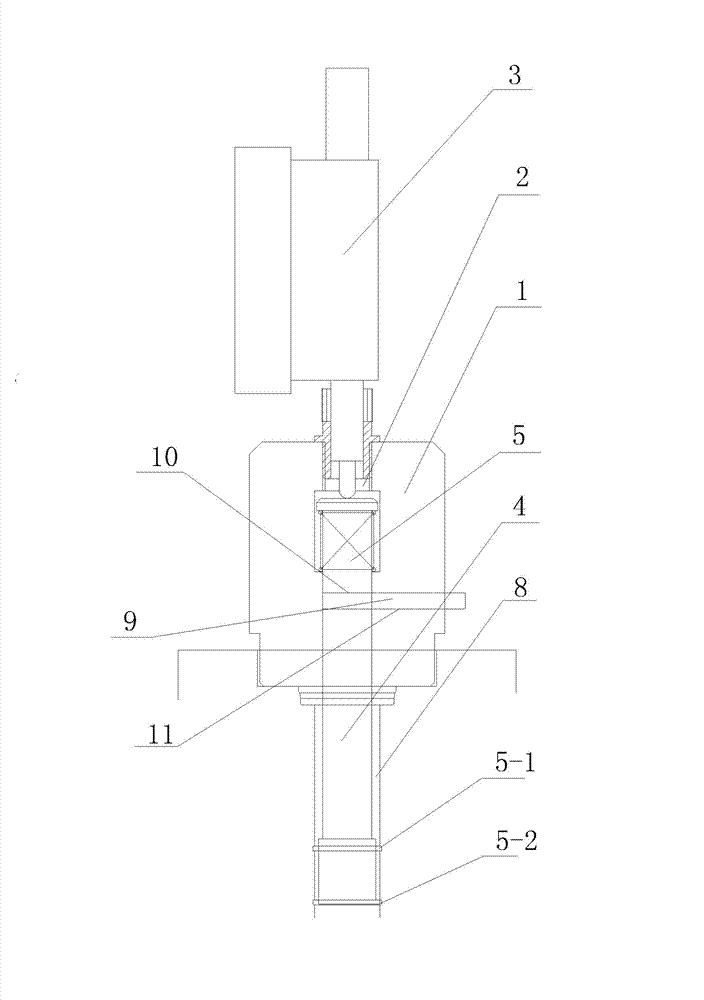

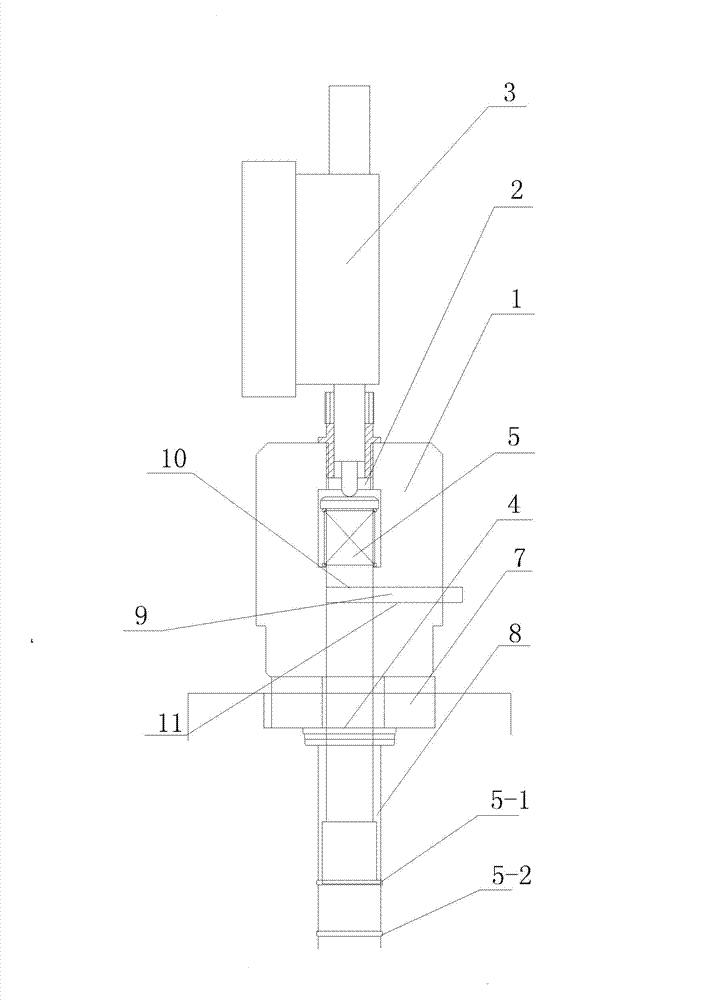

[0010] See figure 1 , figure 2 , image 3 As shown, a depth gauge with multiple oil grooves in a hole includes a measuring body 1, a measuring instrument placement hole 2 is arranged on the measuring body 1, a micrometer 3 is placed in the measuring instrument placement hole 2, and a measuring ruler 4 is movably arranged on the measuring instrument by a spring 5. On the measuring body 1, one end of the measuring ruler 4 is connected to the micrometer 3, and one end of the measuring ruler 4 is provided with protrusions 6 that cooperate with the oil grooves 5-1, 5-2, and the measuring ruler 4 is equipped with detachable measuring instruments of various specifications. Block 7, the measuring block 7 cooperates with the datum surface of the workpiece 8, and the height of the measuring block 7 corresponds to the distance between the oil grooves 5-1 and 5-2 in the hole. Measuring body 1 and measuring ruler 4 are provided with matching positioning holes 9,10, and movable positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com