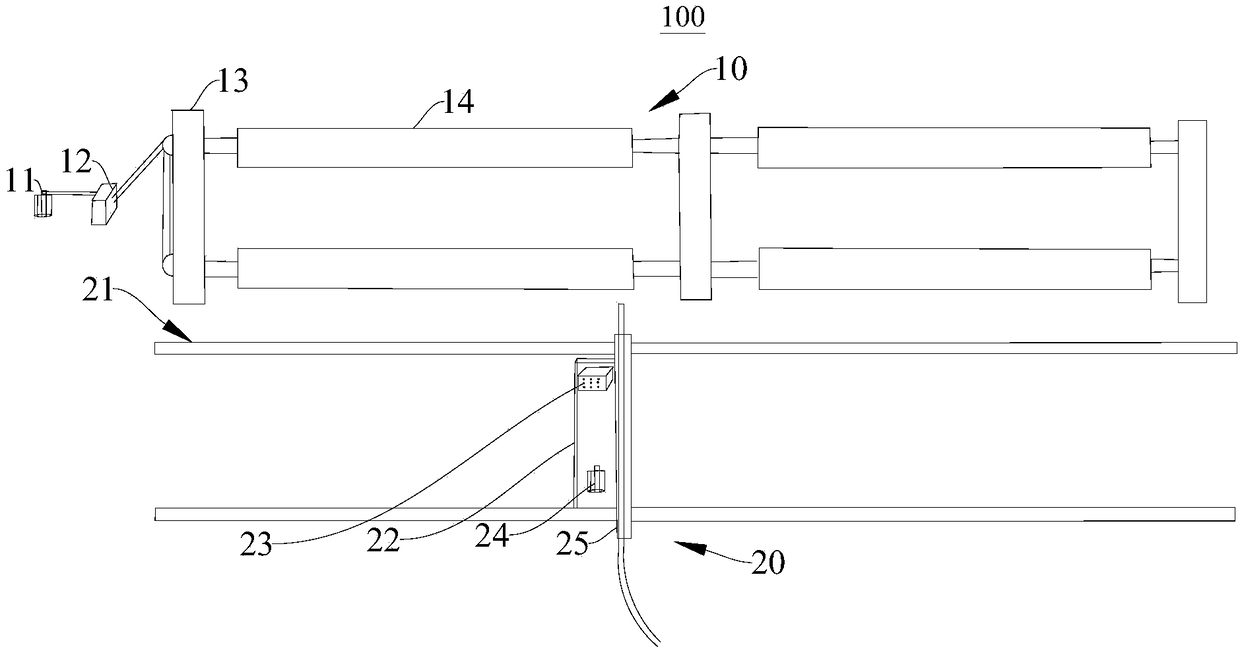

Cage rolling machine

A rolling cage machine and rolling cage technology, applied in the field of rolling cage machine, can solve the problems of large engineering volume, deviation of the process adaptability of automatic rolling cage machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

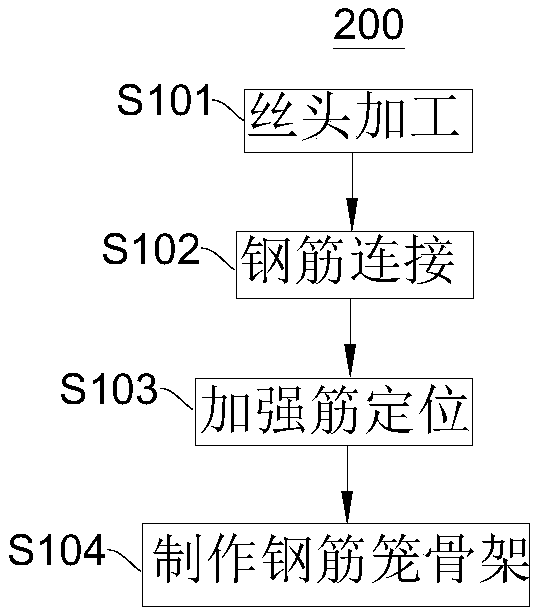

Method used

Image

Examples

Embodiment Construction

[0025] According to statistics, the conventional steel cage processing team is 6-8 people, working 11 hours a day to produce 7-8 steel cages. After on-site investigation and inventory, in the production process of steel cages, the most difficult production is the coiling and fixing of stirrups. According to statistics, this process takes the longest time. In addition, the traditional hand-made steel cages are inefficient, and the labor force is too large to meet the increasing production pressure and on-site demand; the initial investment in fully automatic steel cage processing equipment is large, which virtually increases the pressure of project cost control. The volume of equipment is generally large, and the installation and disassembly procedures in complex site conditions are complicated. Therefore, the rolling cage machine process has strong adaptability and greatly saves the cost.

[0026] In order to make the purpose, technical solutions and advantages of the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com