Claw pole type motor

A technology of motors and claw poles, which is applied to electric components, synchronous motors with stationary armatures and rotating magnets, synchronous machines, etc., can solve the problems of increasing the manufacturing cost of motors, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

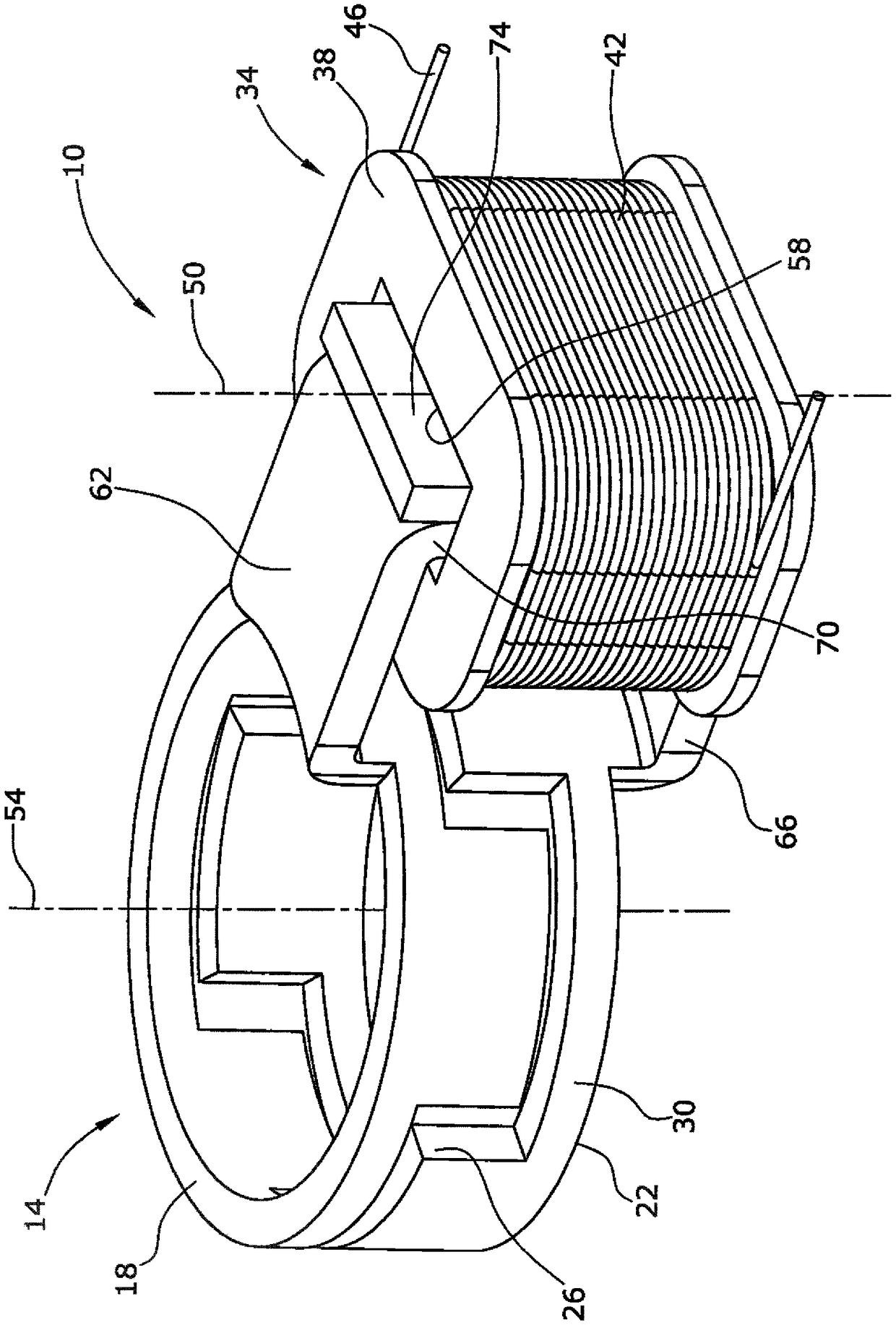

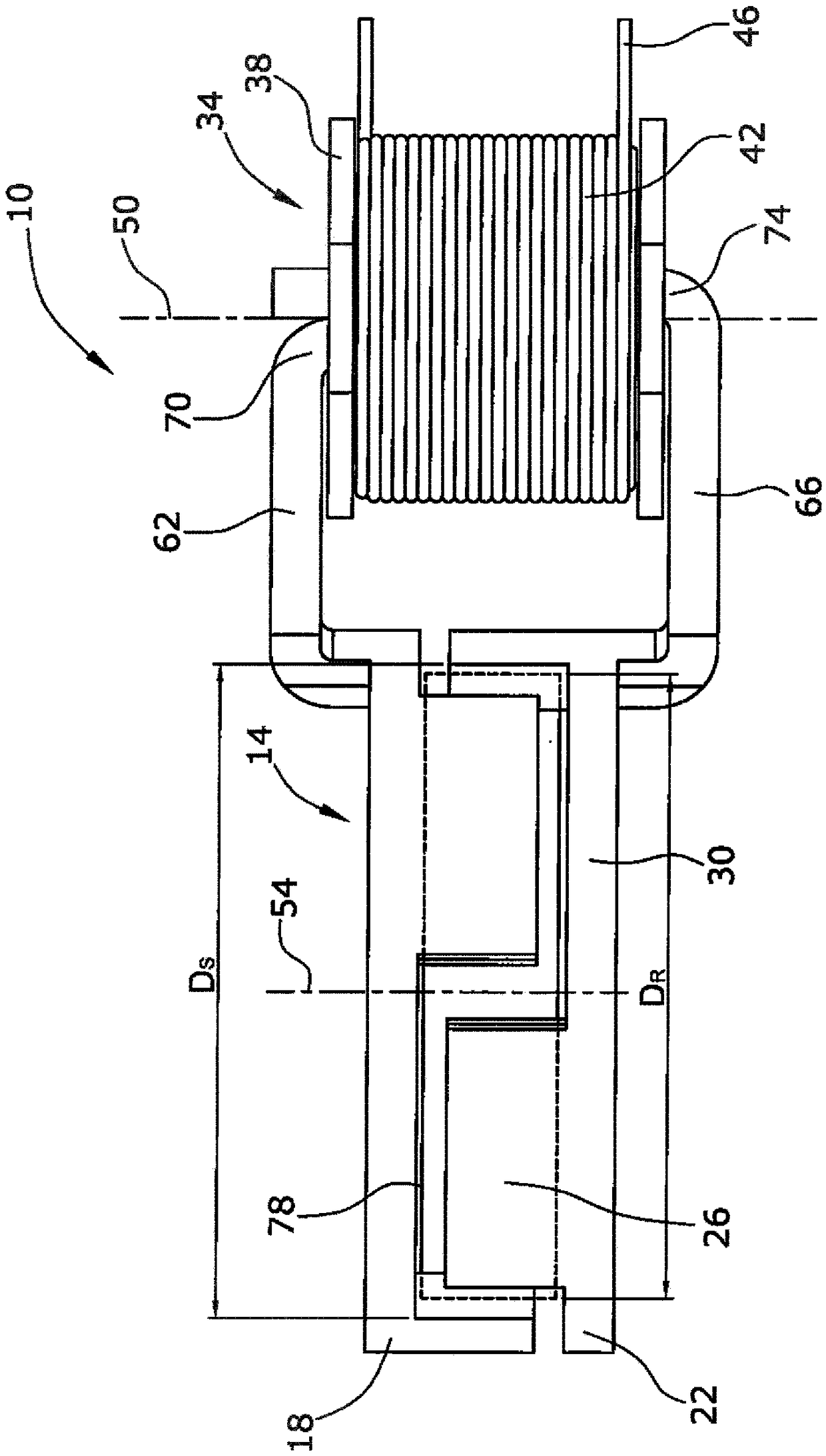

[0022] figure 1 Shown is a perspective view of an automotive single-phase electric motor 10 of the claw pole type (without a motor rotor) comprising a stator 14 defined by two annular stator bodies 18, 22 made of ferromagnetic stamped Made of bent sheet metal parts. Each body 18 , 22 is provided with three magnetic rectangular-shaped claws 26 which engage with the same number of claws 26 of the other body 18 , 22 . The claws 26 of rectangular shape are connected by a back iron ring 30 . The back iron ring 30 and claw 26 of each stator body 18, 22 are arranged on a single cylindrical face of an imaginary cylinder.

[0023] The electric motor 10 also includes a stator coil arrangement 34 for magnetizing the stator bodies 18 , 22 . The stator coil device 34 is arranged as a satellite with respect to the stator 14 , that is, the stator coil device 34 is arranged at a certain radial distance from the stator 14 . The stator coil arrangement 34 is defined by a cuboidal coil 38 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com