Harmonica

A harmonica and blow-sucker technology, applied in the field of musical instruments, can solve problems such as unsightly appearance, unreliable tightening force of rubber bands, and no sound from reeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

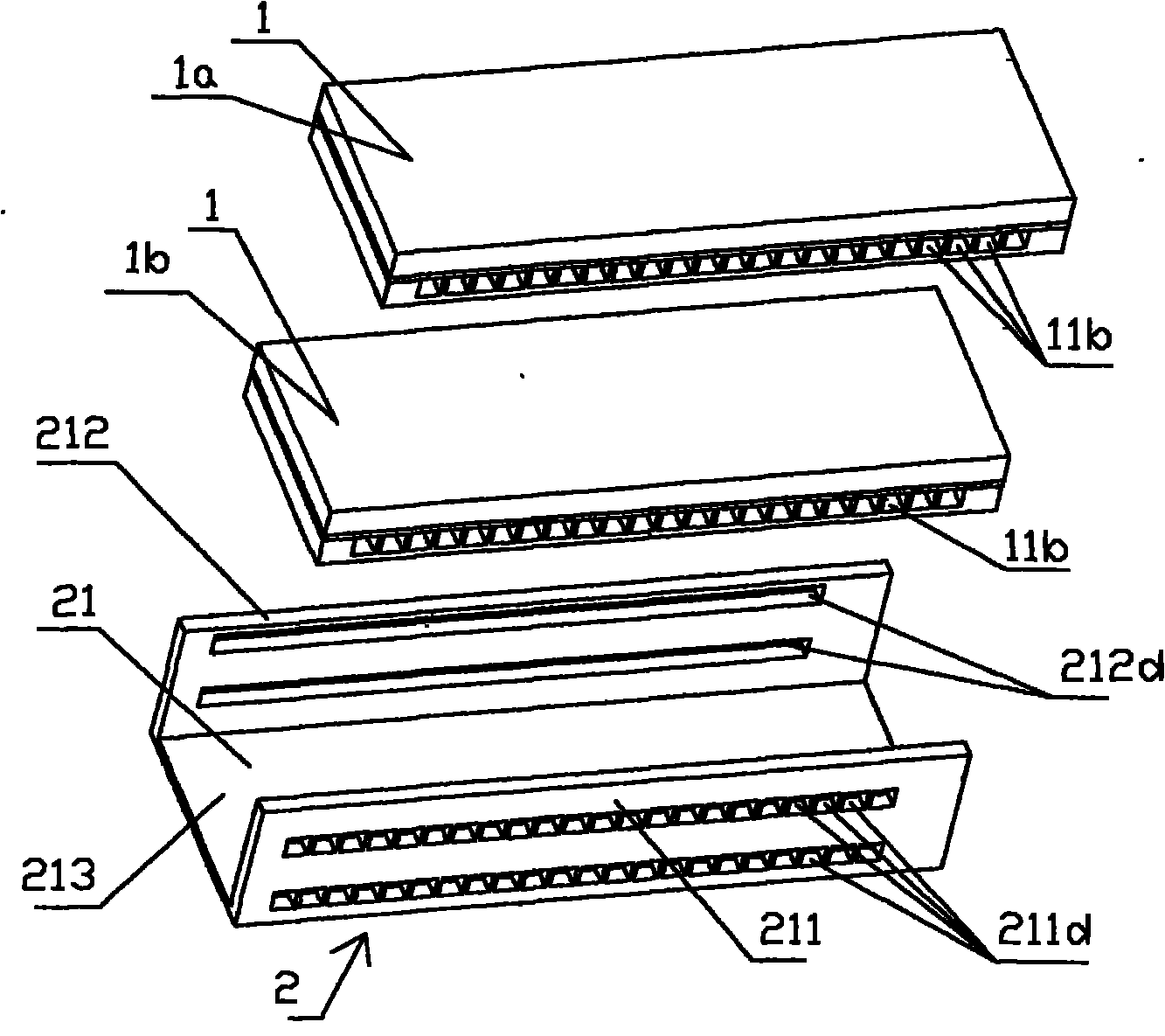

[0085] Embodiment one: if figure 1 As shown, a kind of harmonica described in this embodiment includes an upper layer blowing body 1a, a lower layer blowing body 1b, and a frame seat 2 provided with a groove-shaped accommodation portion 21, the upper layer blowing body 1a, the lower layer blowing body The suction body 1b can be superimposed on each other and placed in the groove-shaped accommodating portion 21. The groove-shaped front groove wall 211 has an opening 211d corresponding to the sound lattice opening 11b of the blow-suction body 1. In this embodiment , the front groove wall 211 corresponds to the same number of sound grid openings 11b of the front blowing surface 16 in the two blowing bodies with forty-four mouths; There is no component for changing sound or snapping in other embodiments below, and the components for changing sound or snapping of the frame seat 2 are generally installed on the left and right sides of the groove-shaped accommodating portion 21 .

...

Embodiment 2

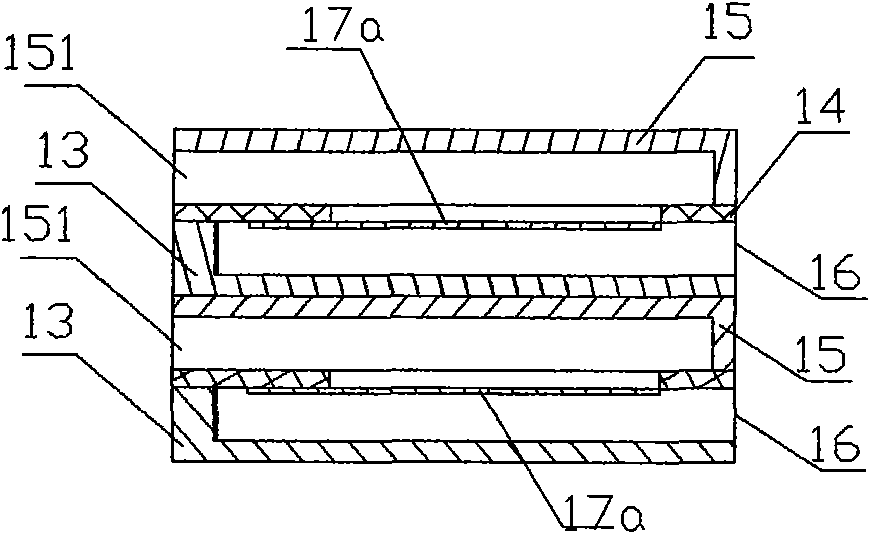

[0092] Embodiment two: if Figure 6 As shown, the front groove wall 211 of the harmonica in this embodiment is provided with a voicing slider 3 in front, and the frame seat 2 is provided with a positioning opening 31 of the voicing slider 3 that can make the voicing slider 3 Positioner 6 for movement and reset. This locator 6 can be called the phonogram slider locator 6 . The positioning part 6 of this embodiment is a torsion spring 61, and the torsion spring 61 is sleeved on the cylindrical support 24. The end wire 611 at one end of the torsion spring 61 leans against a supporting wall 25, and the end wire 612 at the other end leans against the other end. On the support wall 26, the head of the end wire 612 at the other end is inserted in the positioning opening 31 of the sound changing slider. The hand pushes or moves the end of the phonogram slider 3, and the phonogram slider 3 starts to move. When the phonogram slider 3 moves a distance of one sound frame 131, or roughly...

Embodiment 3

[0099] Embodiment three: as Figure 12 As shown, the front groove wall 211 of the harmonica in this embodiment is provided with a voicing slider 3 in front, and the frame seat 2 is provided with a positioning opening 31 of the voicing slider 3 that can make the voicing slider 3 Positioner 6 for movement and reset. In this embodiment, the positioning member 6 is a rigid pin 62, and the pin 62 is arranged in the moving member 63, and can be clamped and fixed by both the moving member 63 and the small splint 64 as shown in the figure. The moving part 63 is provided with an elastic return mechanism 65 (here is a spring, and is a stage clip), the moving part 63 moves in the groove 28, and the upper small cover 72 is above the moving part 63 (not shown), preventing the moving part 63 from breaking away from the groove . The hand pushes or moves the end of the sound-changing slider 3, and the sound-changing slider 3 begins to move, and the sound-changing slider drives the pin 62 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com