Labor-saving punching machine

A technology of punching machine and pivoting part, which is applied in the field of punching machines, can solve the problems of insufficient punch distance and poor labor-saving effect, and achieve excellent labor-saving effect and increase the number of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

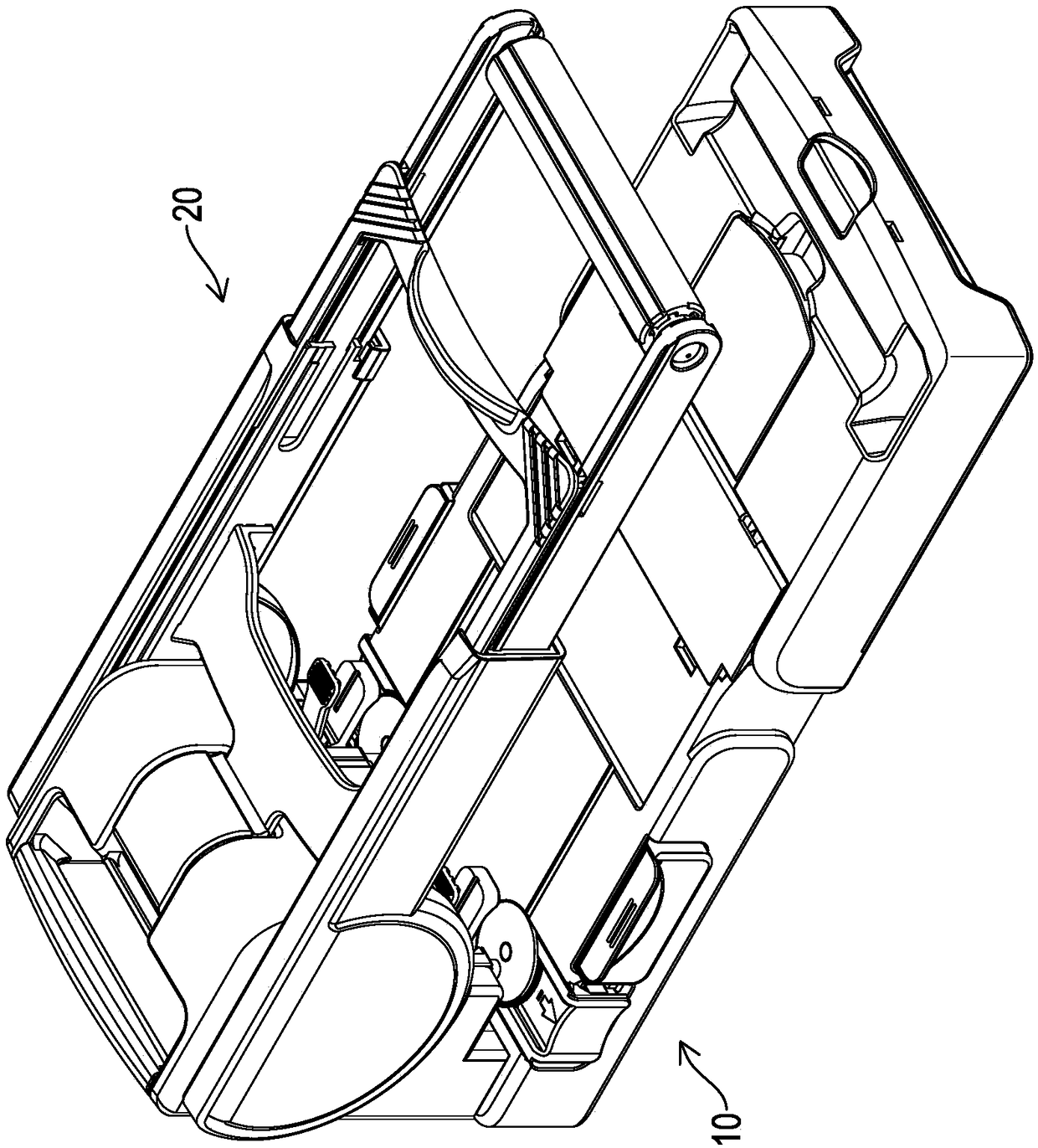

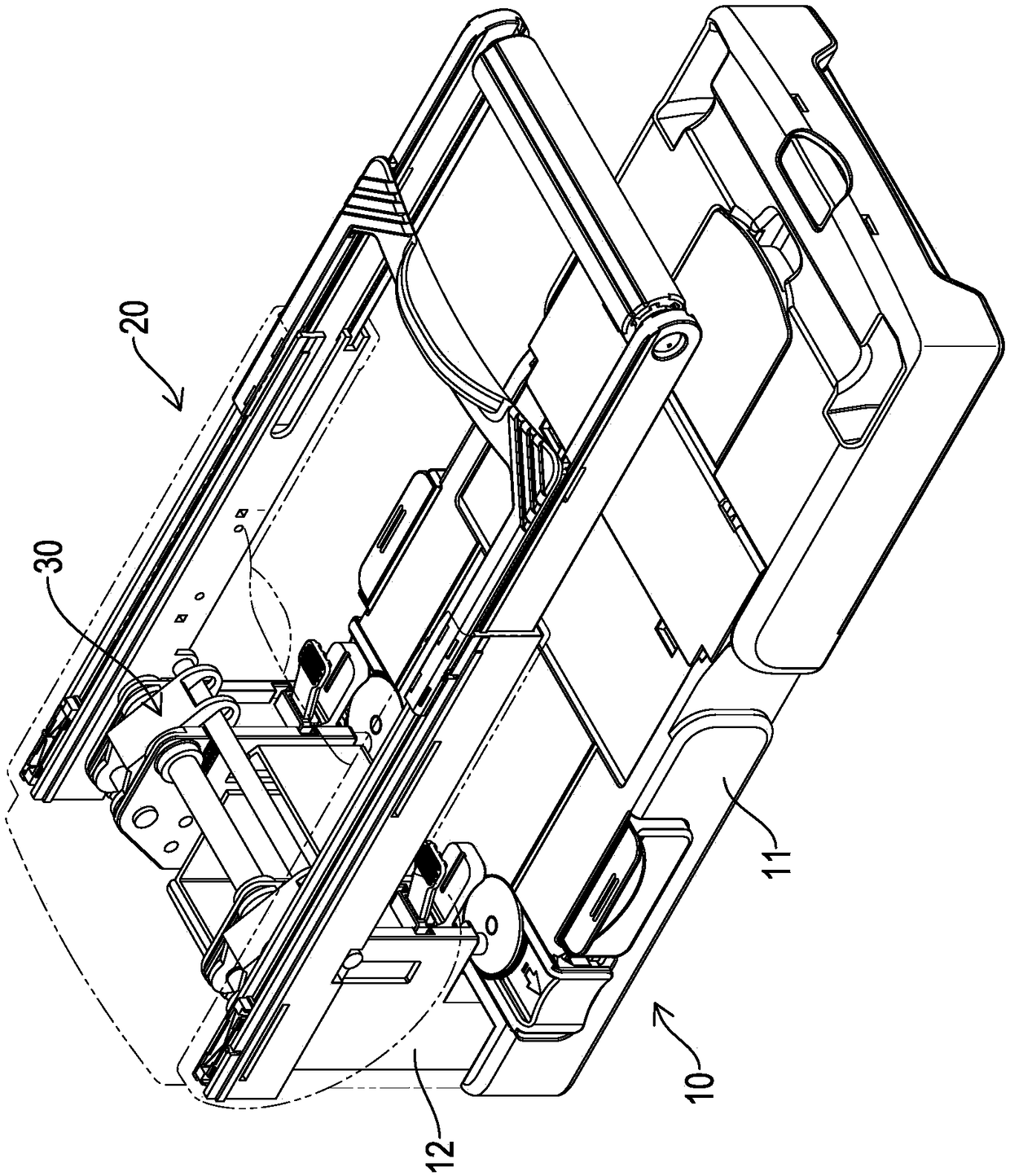

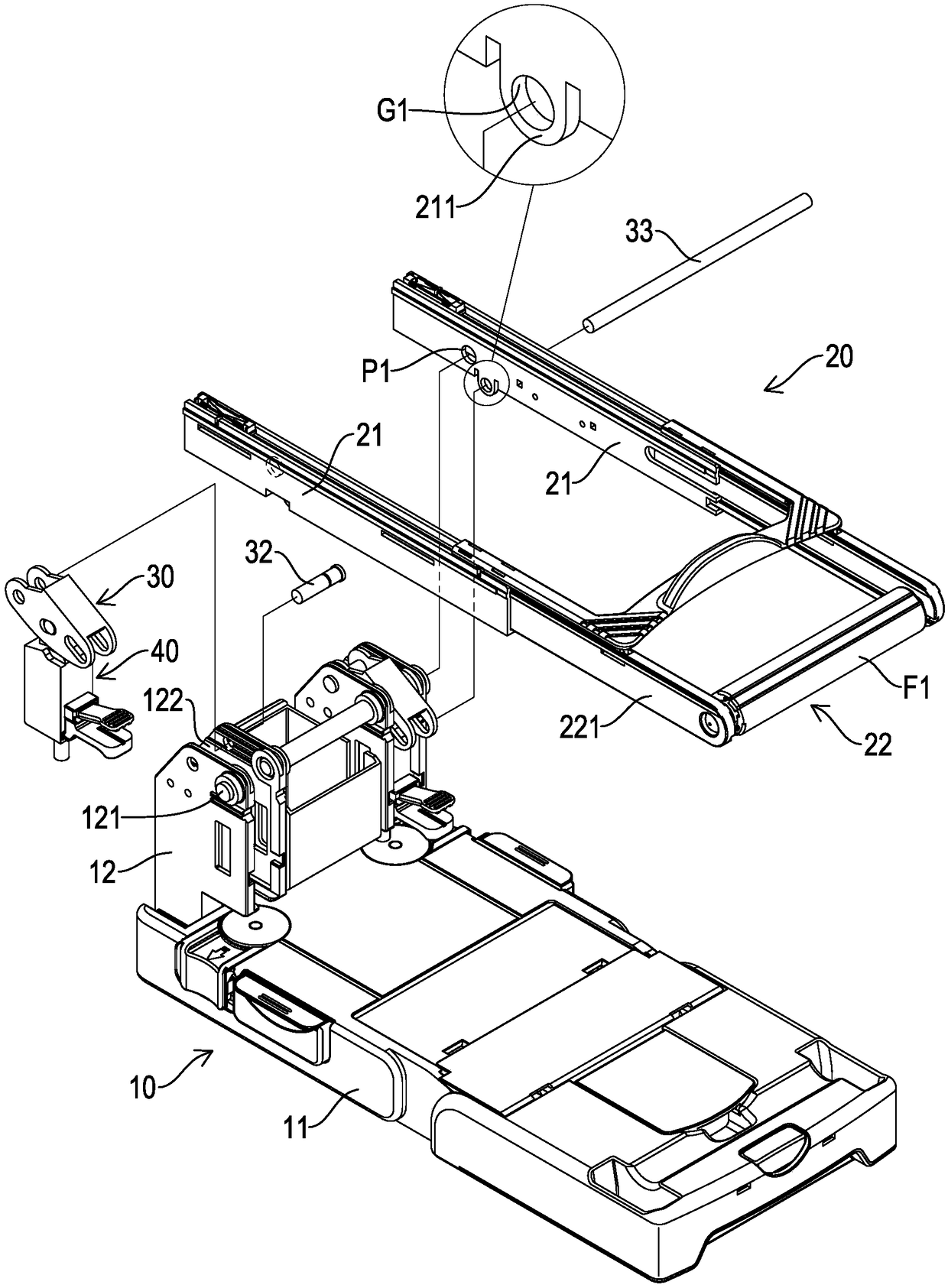

[0036] In order to be able to understand the technical characteristics and practical effects of the present invention in detail, and to implement them according to the contents of the specification, the preferred embodiment shown in the drawings is further described in detail as follows, please refer to Figure 1 to Figure 4 The first preferred embodiment of the present invention includes a base 10 , an operating component 20 , a connecting component 30 and at least one punch component 40 .

[0037] Such as figure 1 and figure 2 As shown, the base 10 includes a base body 11 and two fixing frames 12 upright connected to the base body 11. Preferably, in this embodiment, the base body 11 is foldable or shrinkable to change its length. , the two fixing frames 12 are respectively arranged parallel to each other and spaced apart from one end of the base body 11, each fixing frame 12 is respectively provided with a pivoting member 121 protruding outward, and an assembly space 122 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com