pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire edges, tire sidewalls, etc., can solve problems such as insufficient research, achieve excellent durability, and promote heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

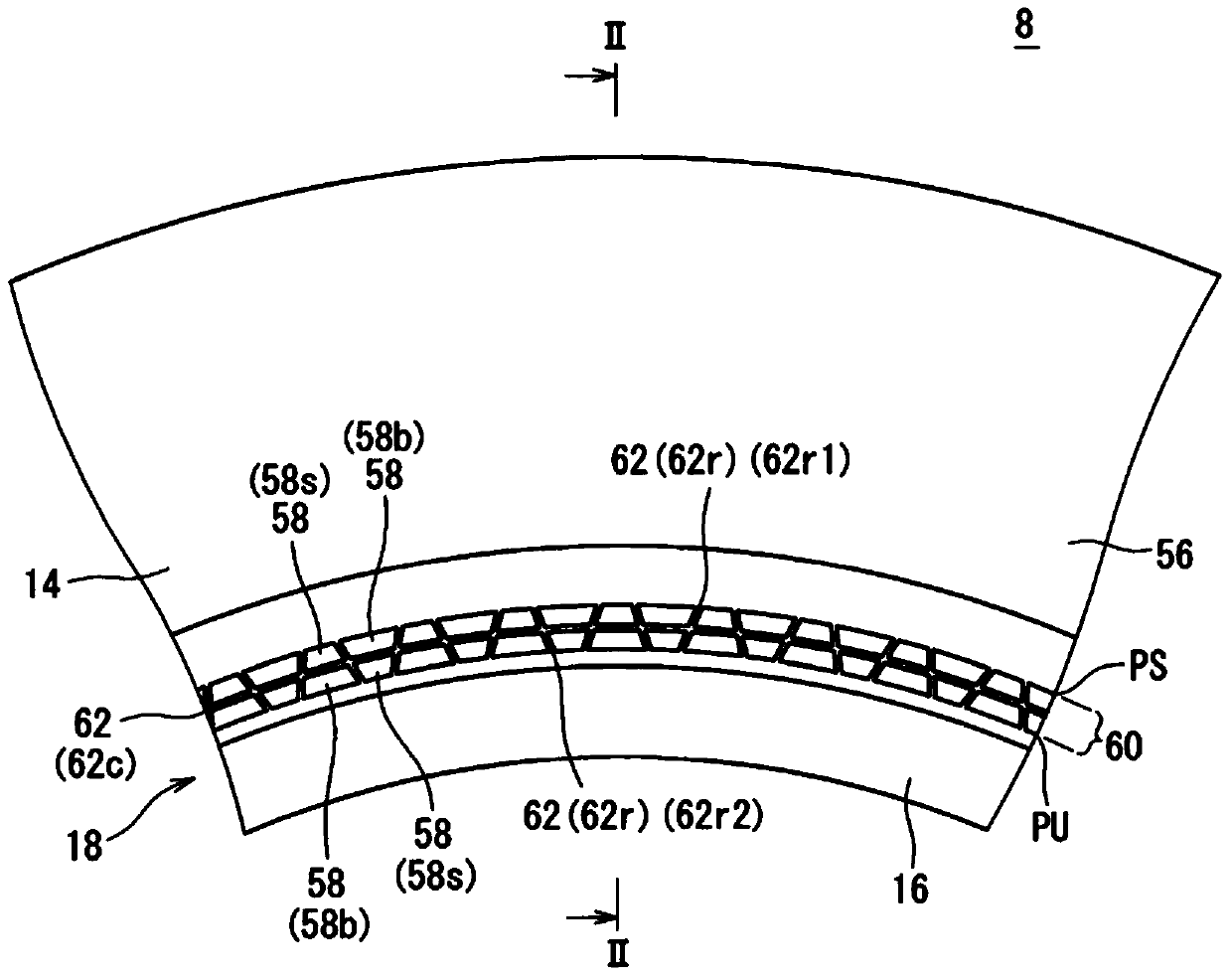

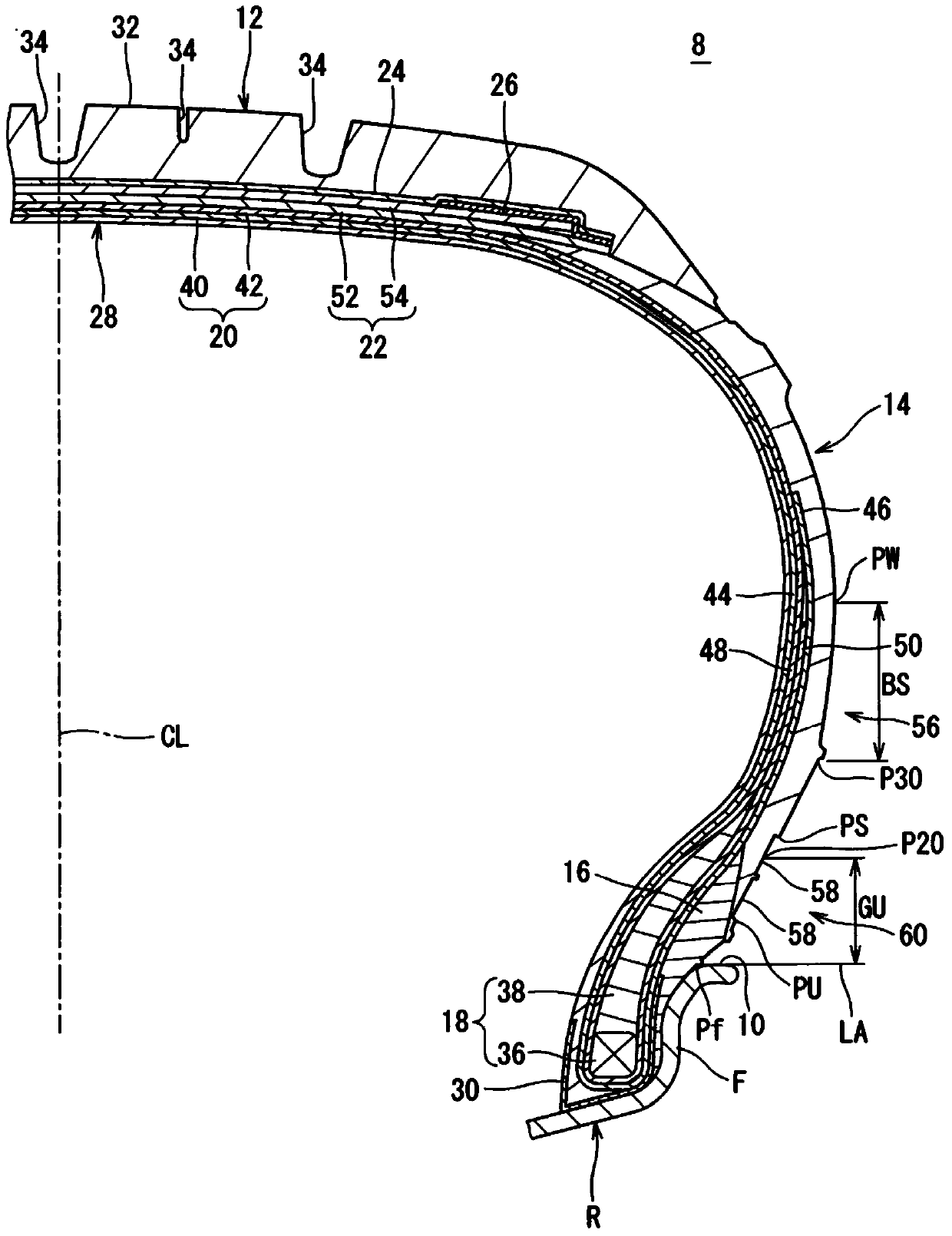

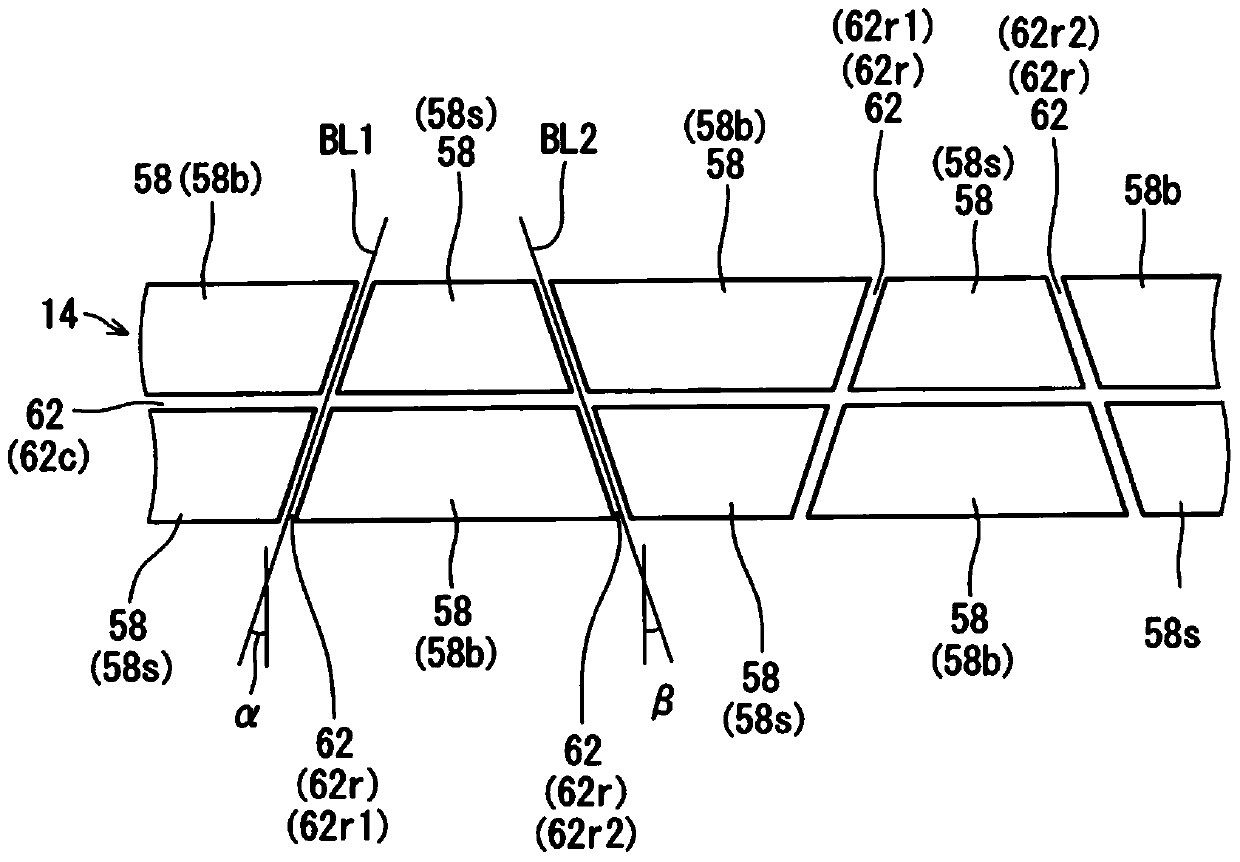

[0078] Prototype Figure 1 ~ Figure 3 tires shown. The size of this tire is 245 / 75R16. The specifications of the concavo-convex portion in this Example 1 are shown in Table 1 below.

[0079] In this tire, the outer edge PS of the concavo-convex portion is located radially inward from the position P30. This case is indicated by "GS" in the column of "outer edge of concavo-convex part" in Table 1. The inner edge PU of the concavo-convex portion is located between the position Pf and the position P20 in the radial direction. This case is represented by "GU" in the column of "inner edge of concavo-convex part" in Table 1.

[0080] No filler is provided in this tire. This is indicated by "N" in the "Filler" column of Table 1. The carcass of the tire is as figure 2 As shown, it consists of two carcass plies.

Embodiment 2 and comparative example 3

[0084] Tires of Example 2 and Comparative Example 3 were obtained in the same manner as in Example 1, except that the inner edge PU of the concavo-convex portion was arranged radially outward from the position P20. The inner edge PU of the concave-convex portion is located radially outward from the position P20, which is indicated by “BU” in the column “Inner edge of the concave-convex portion” in Table 1. In Comparative Example 3, the outer edge PS of the concavo-convex portion is located between the position PW and the position P30 in the radial direction. This case is indicated by "BS" in the column of "outer edge of concavo-convex part" in Table 1.

Embodiment 3 and comparative example 4~6

[0086] Tires of Example 3 and Comparative Examples 4 to 6 were obtained in the same manner as in Example 1 except that the structure of the concavo-convex portion was shown in Table 2 below. In Example 3, a triangular dimple is formed between the first land portion and the second land portion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com