Stepped cylinder centering device

A centering device and cylinder technology, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems of low production efficiency and waste of time, and achieve the effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

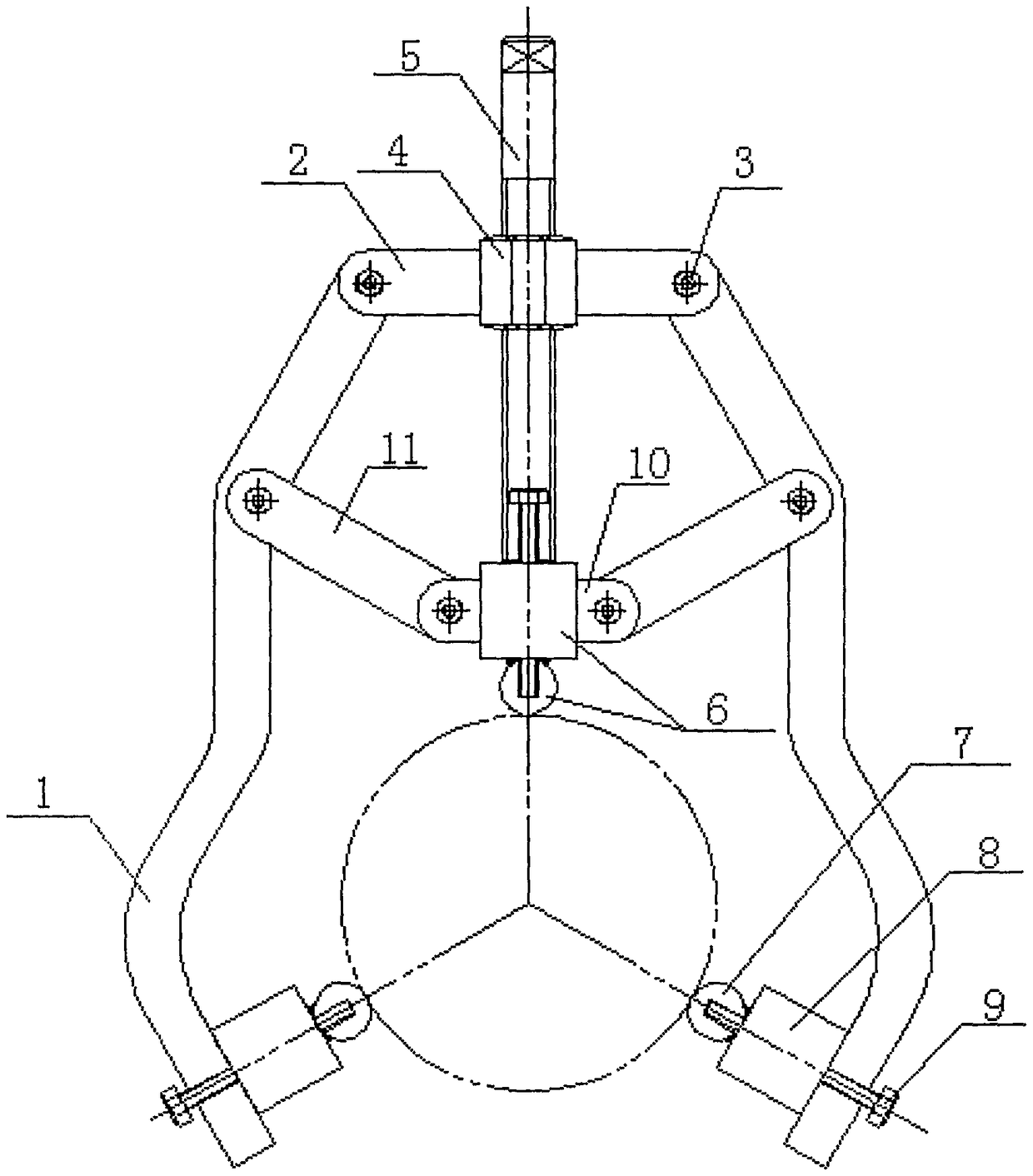

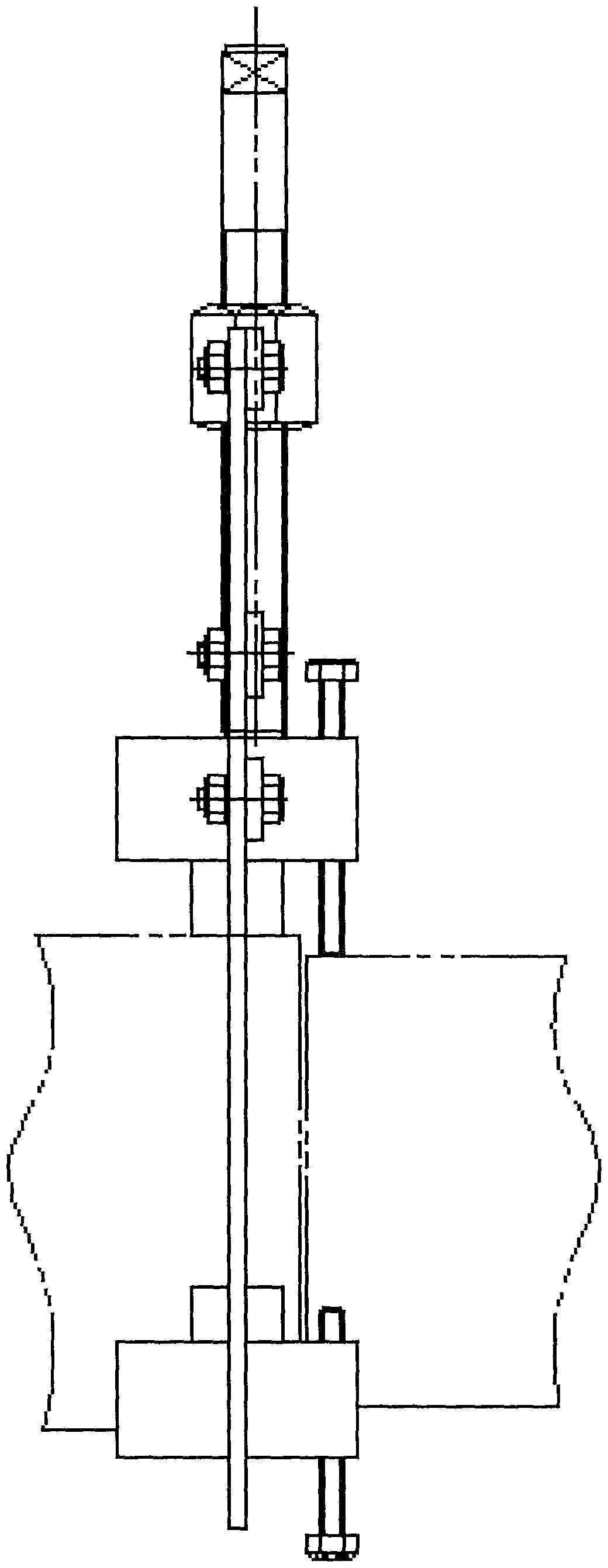

[0013] 1. First process the arms 1 on both sides. The arm plate 1 is cut from a steel plate. Connect the two ends of the arm plate 1 and the top transverse connecting plate 2 through bolts 3. Divide the middle position of the top transverse connecting plate 2 into two halves and connect the nuts 4 Welding, the top transverse connecting plate 2 is cut from the steel plate.

[0014] 2. Screw the wire 5 into the nut 4, weld the positioning block 6 at the bottom of the screw, the positioning block 6 is composed of the positioning plate 8 and the round steel 7, the positioning plate 8 is welded to the round steel 7, and drill on the side of the positioning plate 8 hole and buckle, screw the screw 9 into the hole.

[0015] 3. Weld the middle transverse connection plate 10 at both ends of the positioning plate 8, and connect the middle transverse connection plate 10 to the arm plates 1 on both sides through the bolts 3 through the side connection plates 11 to form a set of linkage me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com