A double-sided printing drying device for woven satin ribbon

A technology of double-sided printing and drying device, which is applied in the field of woven ribbon printing, can solve the problems of ribbon smearing, reducing product quality, and unable to dry ink in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

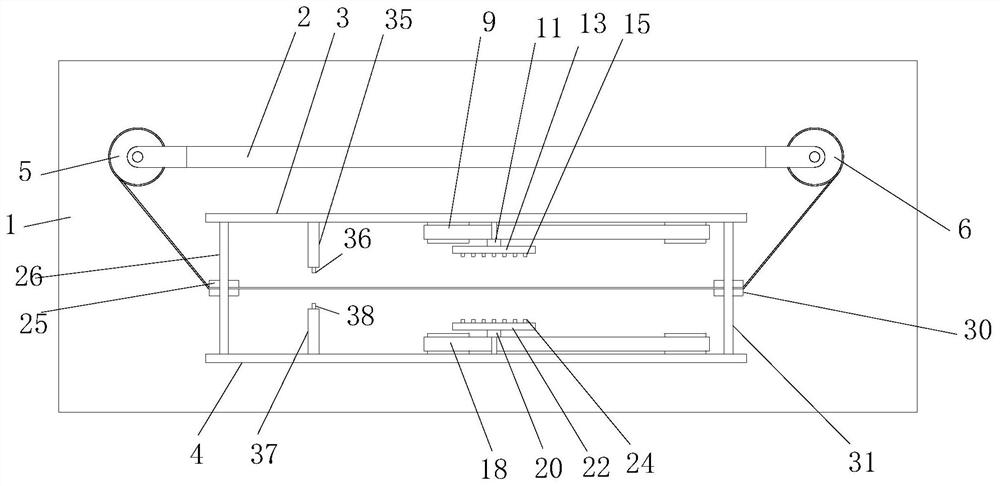

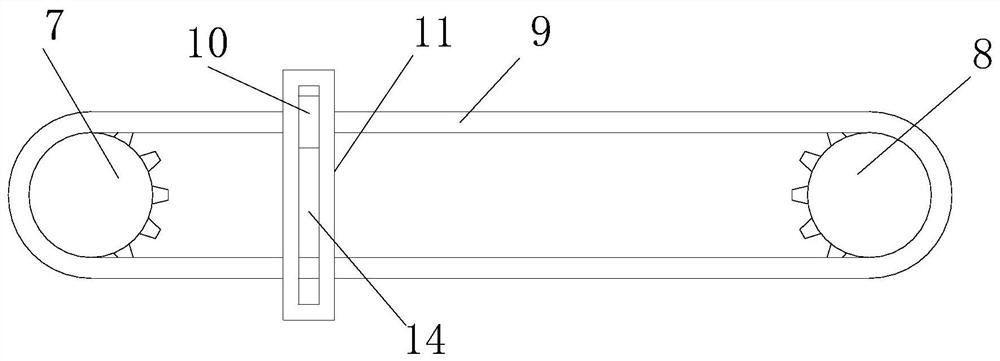

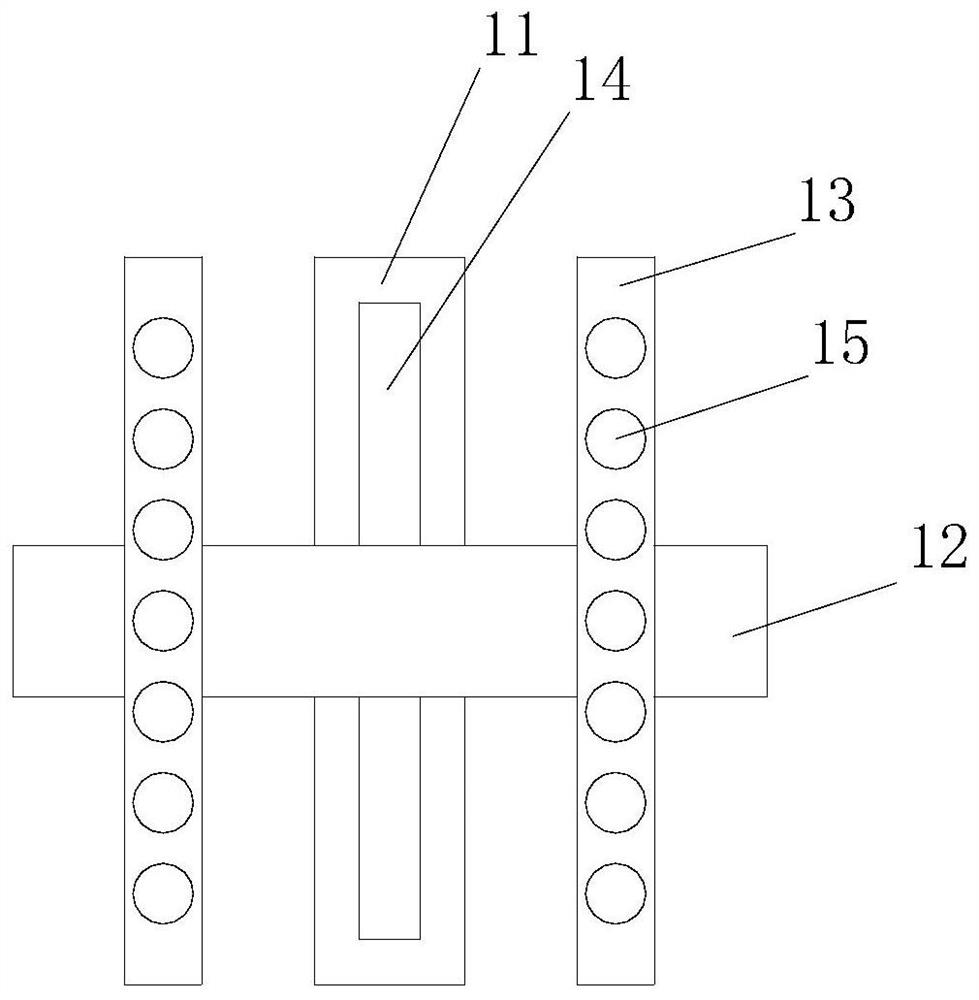

[0024] refer to Figure 1-Figure 7 , The present invention proposes a double-sided printing and drying device for woven ribbon, including a workbench 1, a first mounting plate 2, a second mounting plate 3, a third mounting plate 4, a tape unwinding roller 5, a tape take-up roller 6, a printing mechanism, drying mechanism, first preloading mechanism and second preloading mechanism, wherein:

[0025] The workbench 1 is arranged horizontally, the first installation plate 2, the second installation plate 3, and the third installation plate 4 are vertically installed on the workbench 1, and the first installation plate 2, the second installation plate 3, and the third installation plate 4 are mutually They are arranged in parallel and at intervals, and a processing area is formed between the second mounting plate 3 and the third mounting plate 4 .

[0026] The unwinding roller 5 and the take-up roller 6 are parallel to each other, the unwinding roller 5 is arranged at the feed end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com