Shell core rapid drying and forming process and device

A rapid drying and forming device technology, which is applied to casting and forming equipment, cores, casting molds, etc., can solve problems such as uneven drying and poor drying effect, and achieve increased heating uniformity, increased drying range, Increased drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present application will be further described in detail below with reference to the accompanying drawings.

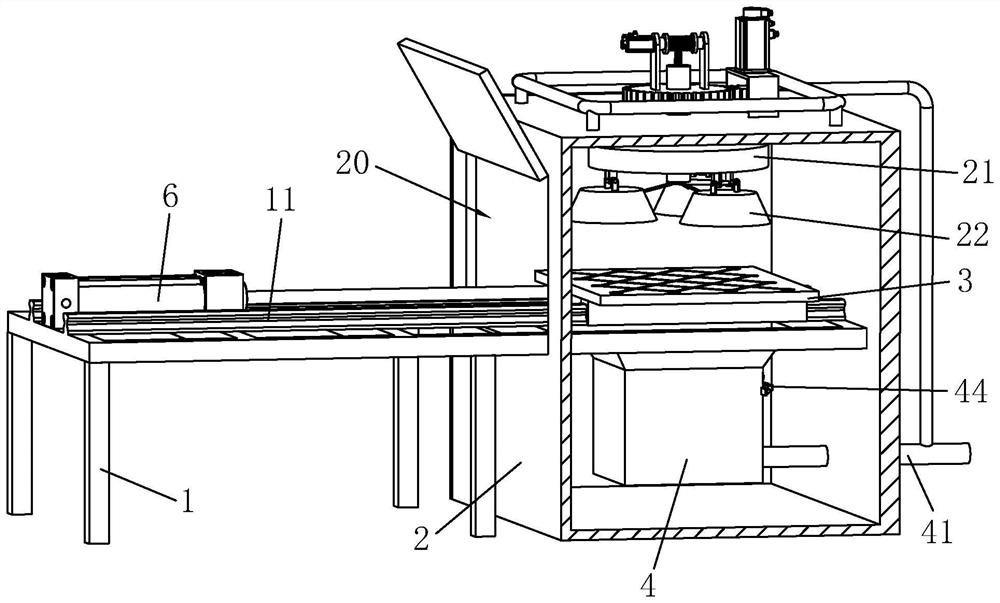

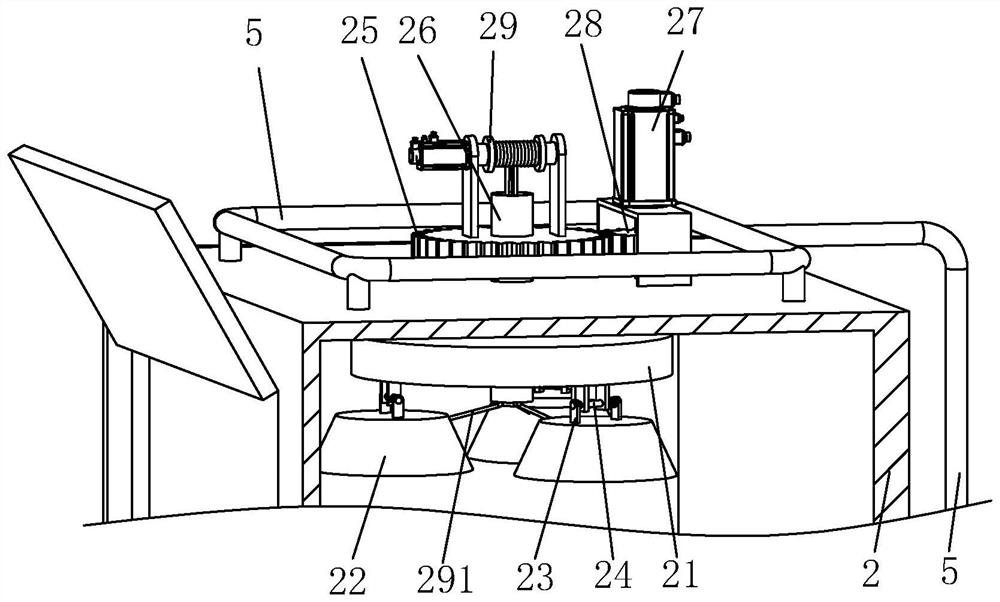

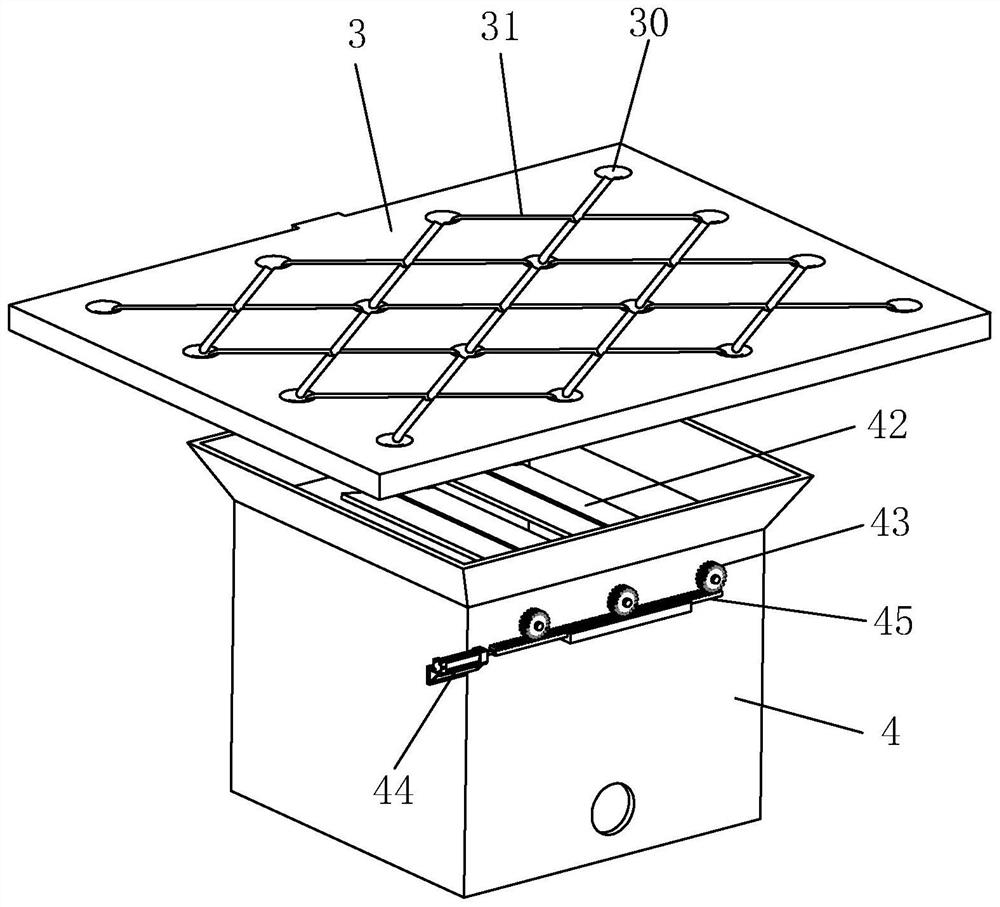

[0037] The embodiment of the present application discloses a shell core rapid drying and forming device, such as figure 1 and figure 2 As shown, it includes: a rack 1, a drying box 2 is installed on the rack 1, the drying box 2 is arranged in a rectangular shape as a whole, and a feeding port 20 is opened on one side of the drying box 2. A slide rail 11 is installed horizontally on the rack 1. The slide rail 11 extends horizontally from the feeding port 20 to the drying box 2. A slide plate 3 is slidably arranged on the slide rail 11, and a plurality of ventilation holes are evenly opened on the slide plate 3. 30. The sliding plate 3 is used to carry the shell core out of the mold. It should be noted that the size of the opening of the feeding port 20 can allow the shell core to enter. In this embodiment, in order to increase the drying effect of the drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com