Quasi-elliptic rolling piston and rolling piston compressor

A rolling piston, elliptical technology, applied in the field of compressors, can solve the problems of large compressors that cannot be rolled piston compressors, increase the movement speed and clearance, and reduce machine performance, so as to eliminate the eccentric mass and centrifugal force, and increase the actual Contact area, effect of increasing curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

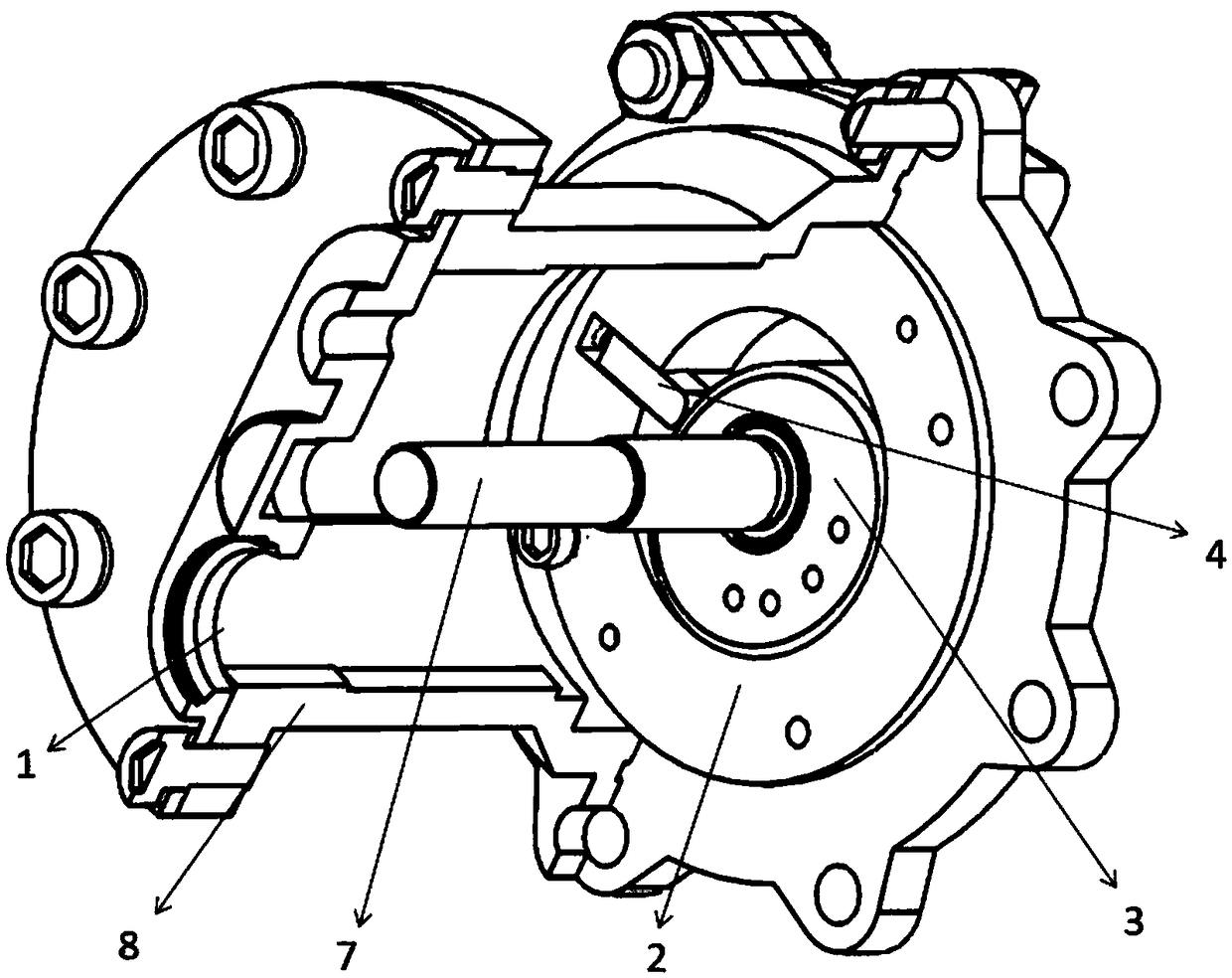

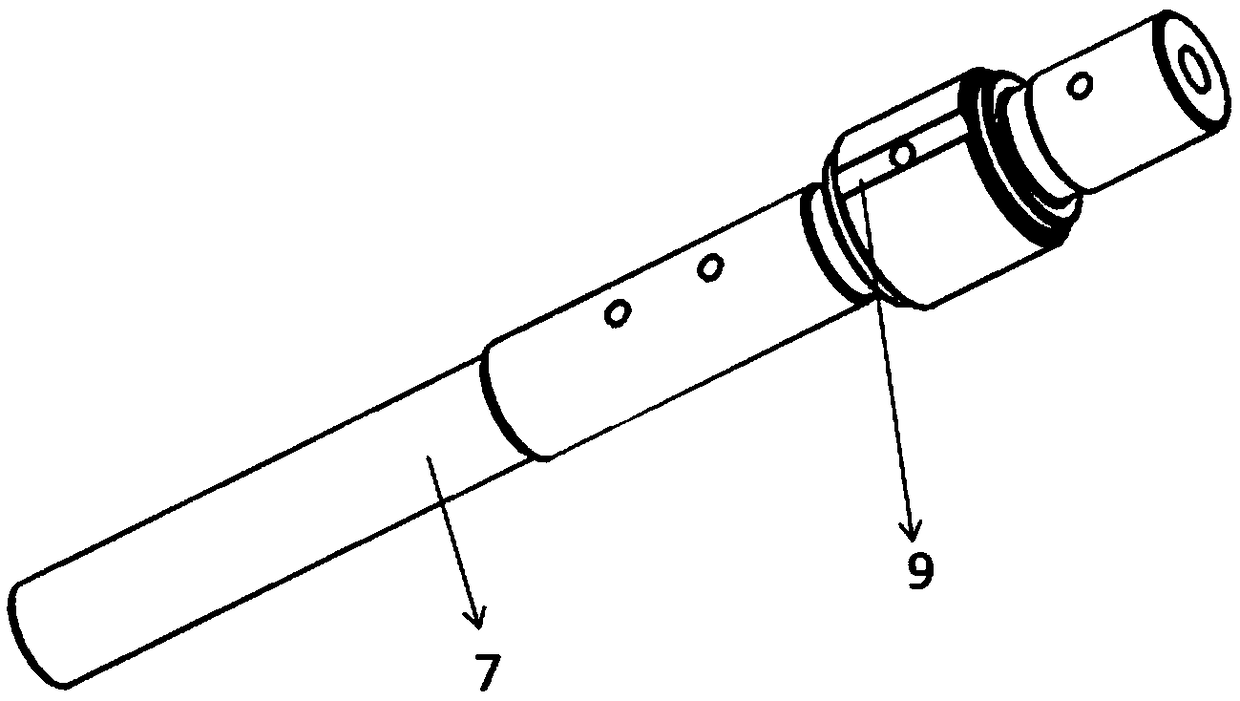

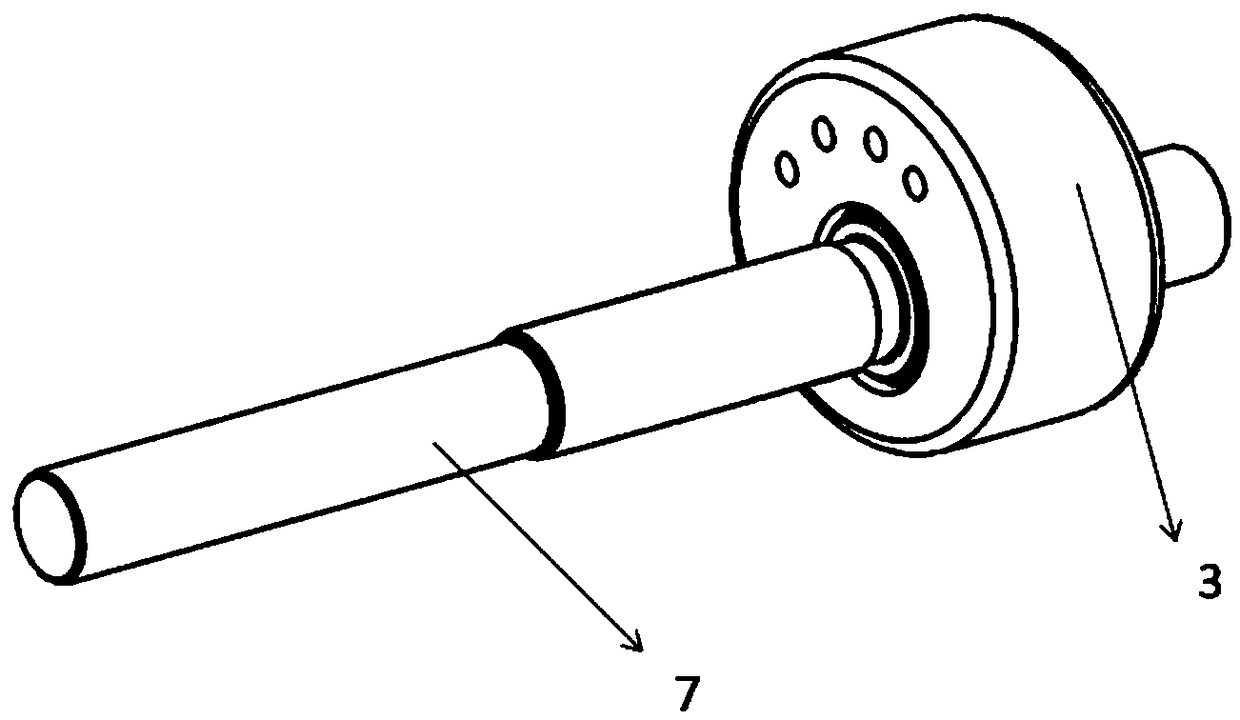

[0027] The present invention adopts the rolling piston compressor of quasi-elliptic rolling piston to comprise cylinder 2, sliding vane 4, piston 3, air intake hole 1, exhaust hole 5, exhaust valve and sliding vane spring 6 structurally, wherein, cylinder 2 Fixed on the casing 8, the piston 3 is connected with the main shaft 7 through a key, and the rotation of the main shaft 7 drives the rolling piston 3 to perform rotational motion. The spring force of the sliding vane spring 6 makes the sliding vane 4 closely contact with the piston 3, and the sliding vane 4 can move up and down, and always contacts with the piston 3. The working process of the compressor of the present invention is as follows: when the tangent point T between the piston 3 and the cylinder 2 reaches the point A of the air inlet 1, the area of the primitive communicates with the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com