Combined anti-lock brake drum for heavy-duty car

A technology of anti-lock braking and heavy-duty vehicles, applied in the direction of brake drums, etc., can solve the problems of braking, increasing the heat dissipation space of brake drums, and easy overheating braking effects, etc., to achieve the effect of ensuring automatic reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

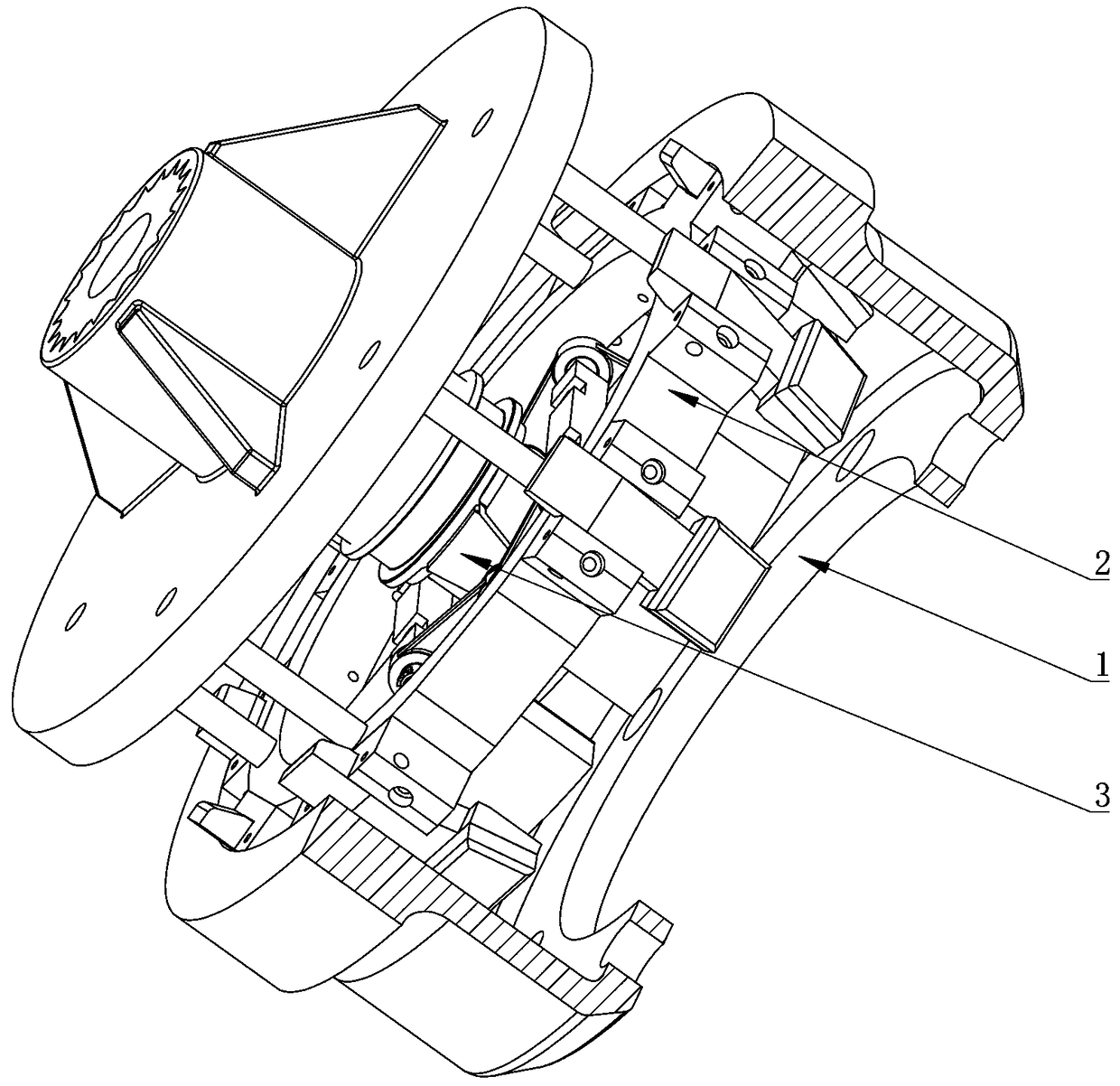

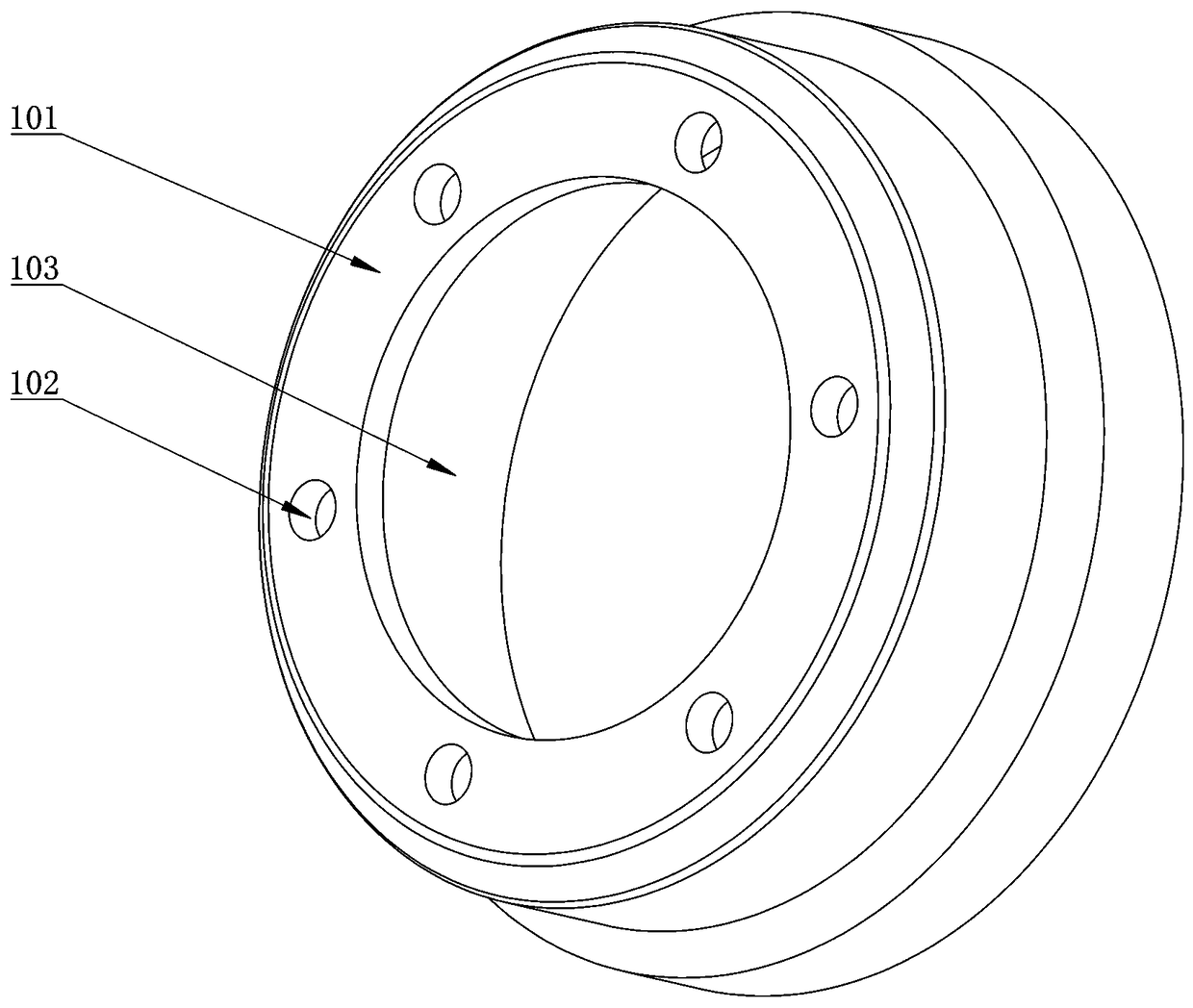

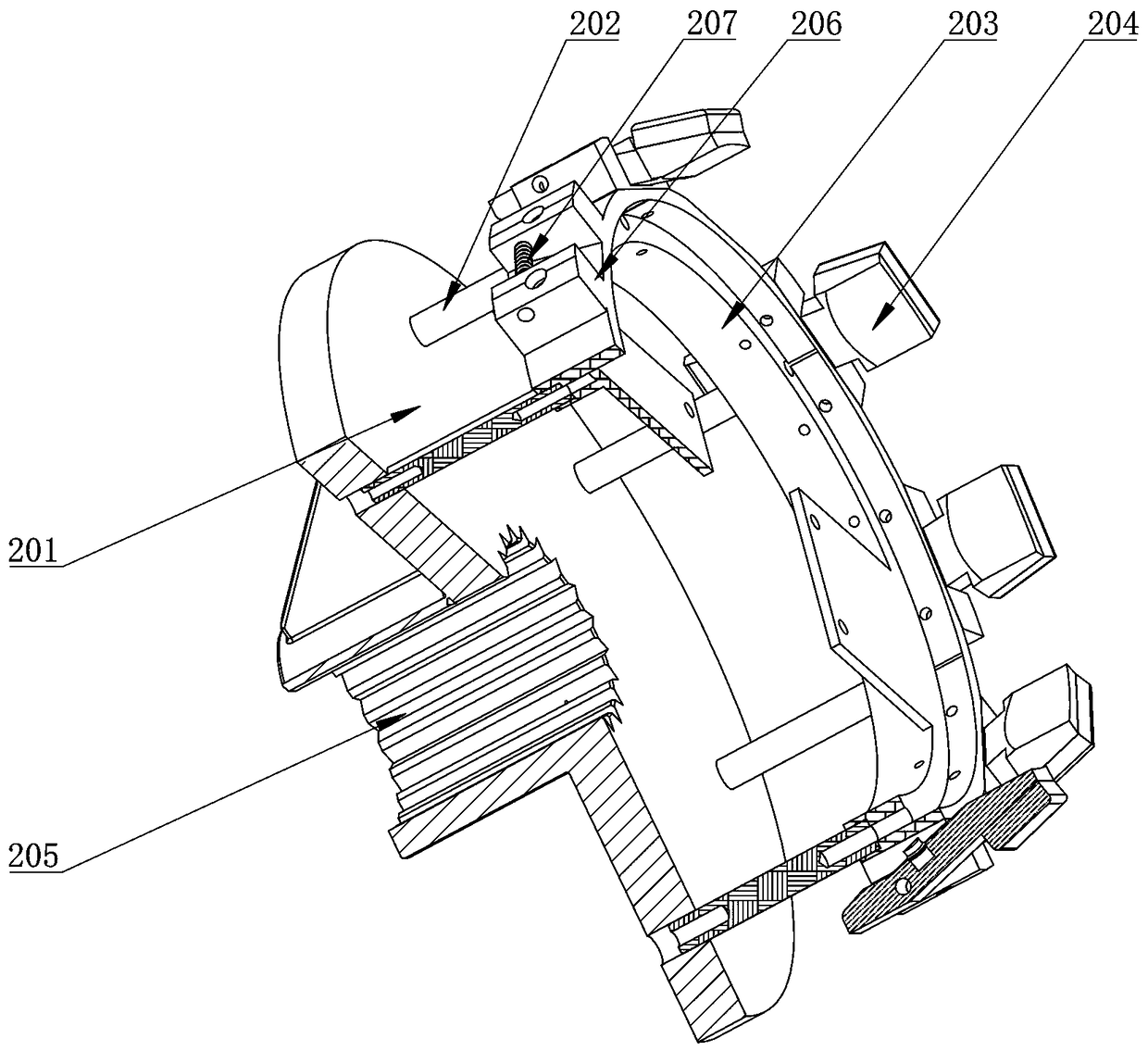

[0016] Specific implementation method: combined Figure 1-5 As shown, it includes a brake drum 1; the narrower end of the upper part of the brake drum 1 is a mounting surface 101; the upper circumference of the mounting surface 101 is uniformly provided with mounting holes 102; the inside of the brake drum 1 is a A moving surface 103; a brake device 2 is provided on one side of the brake drum 1; a drive device 3 is provided inside the brake device 2; a bolt connection is used between the brake device 2 and the drive device 3; The brake device 2 includes a support plate 201, a support column 202, a support ring 203 and a brake shoe 204; the support plate 201 and the support ring 203 are locked by a locking support column 202; the support plate 201 is provided with a spline groove 205 in the middle position of the upper part; a plurality of fixed blocks 206 are uniformly arranged on the outer surface of the support ring 203; bolts are used between the plurality of fixed blocks 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com