Trolley with plastic side plates

A technology of plastic side panels and trolleys, applied in the field of trolleys, which can solve the problems of complicated installation of side panels and low efficiency of disassembly and assembly, and achieve the effect of high disassembly and assembly efficiency and simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

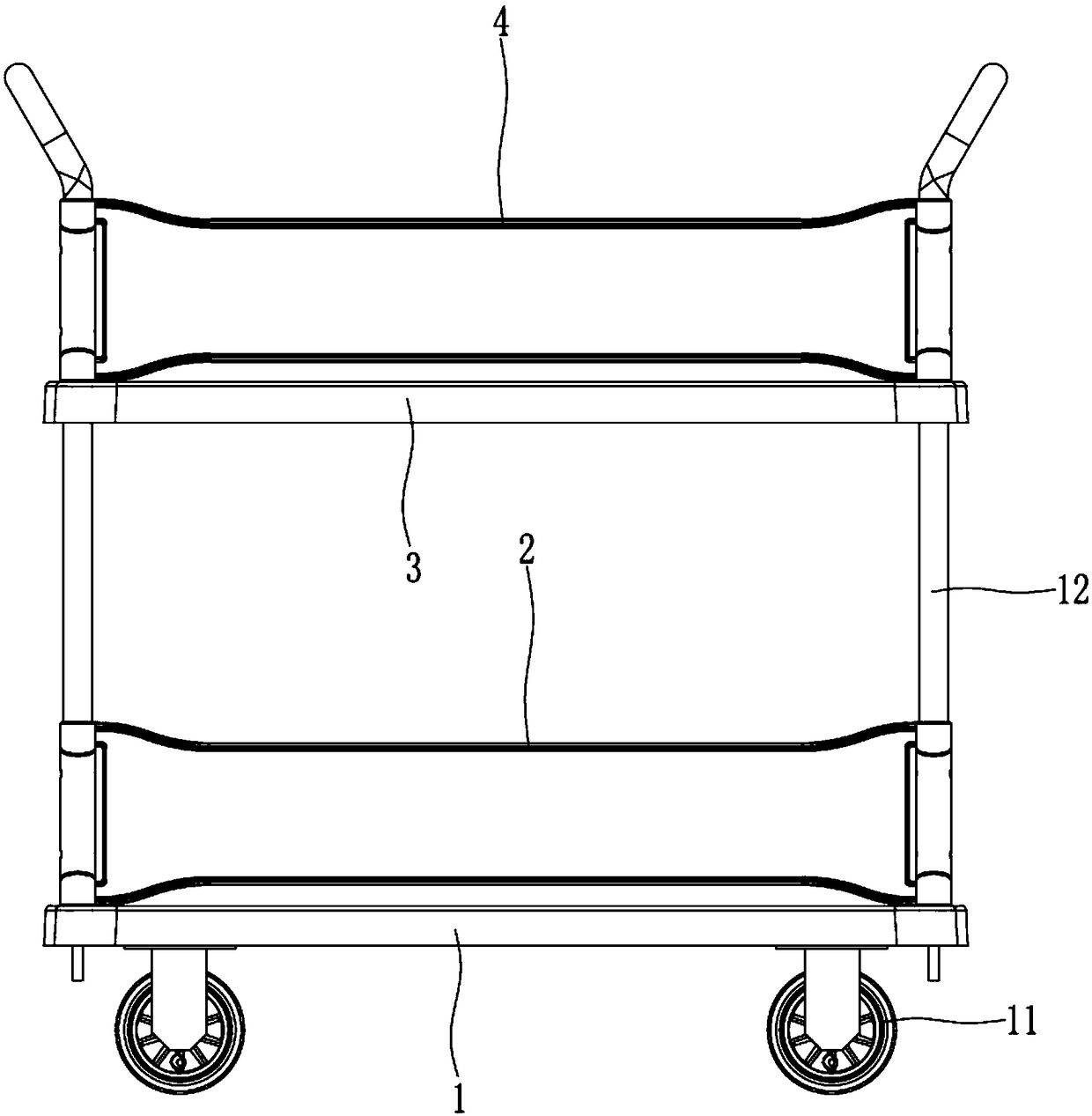

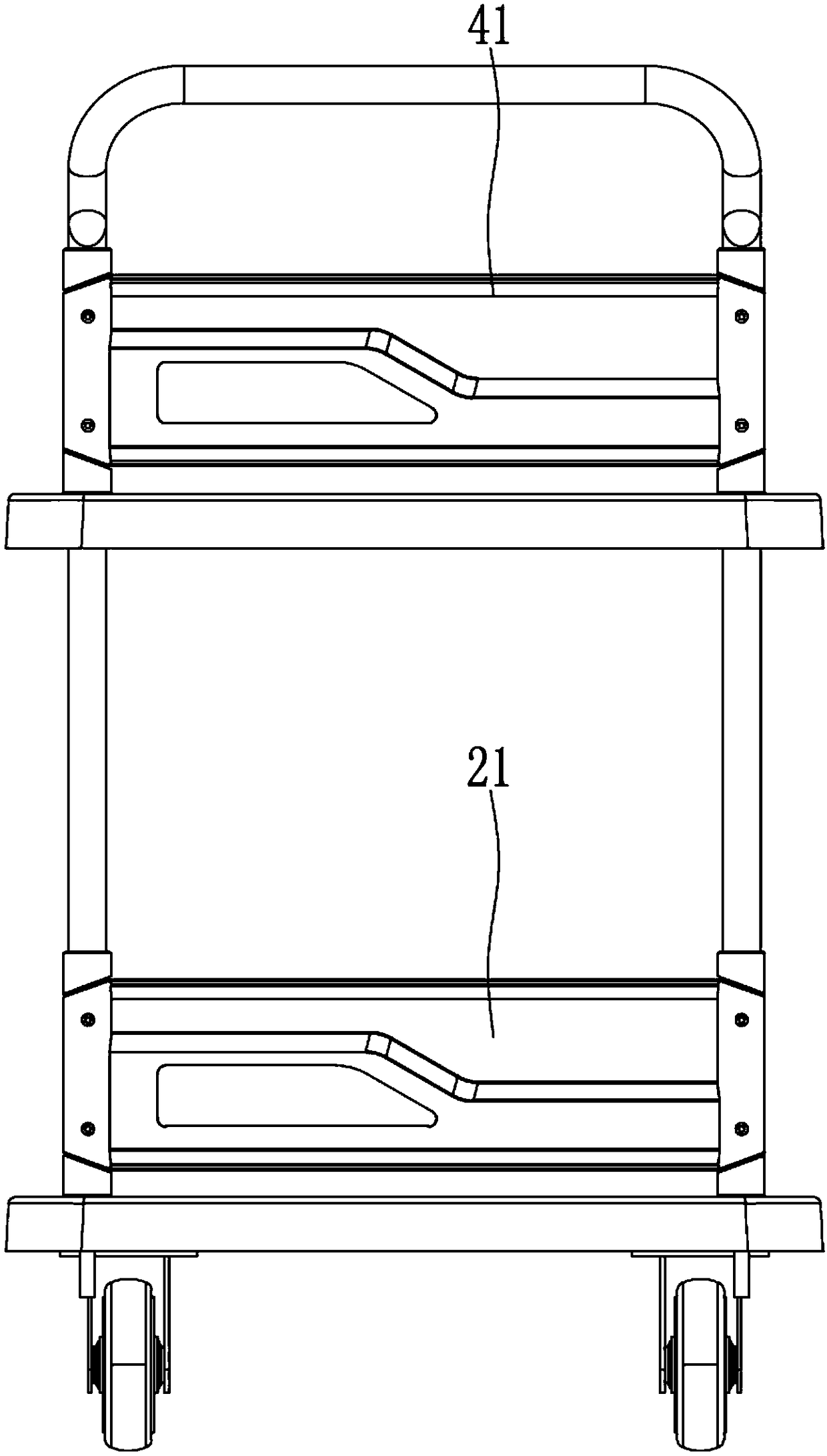

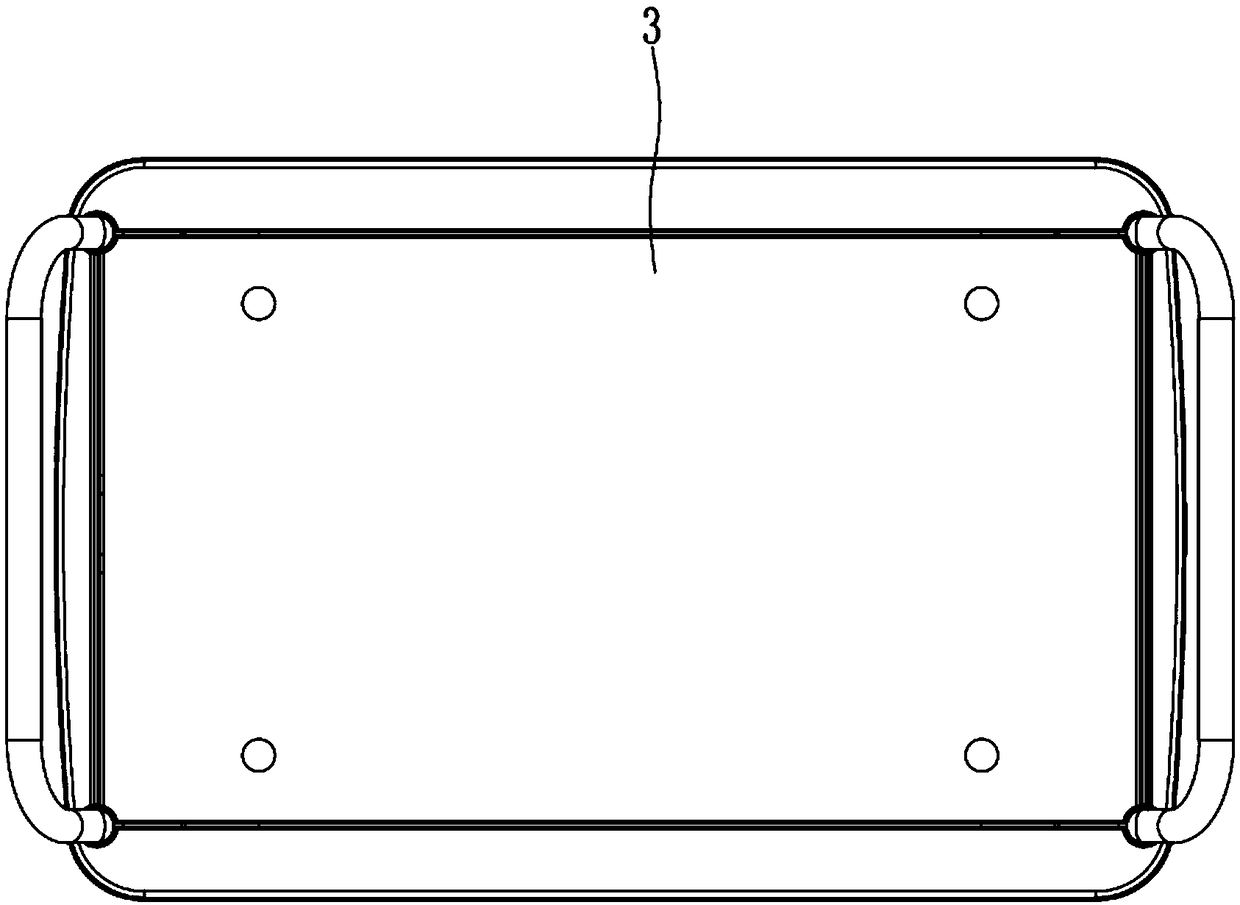

[0027] see Figure 1 to Figure 4 , the figure shows a trolley with plastic side plates provided by Embodiment 1 of the present invention, which includes: a first bottom plate 1, which is a rectangular bottom plate, a plurality of casters 11 are fixedly installed on the bottom of the first bottom plate 1, and Two U-shaped push rods 12 are fixedly installed on the top of a bottom plate 1, and the two U-shaped push rods 12 are arranged oppositely. The U-shaped push rods 12 include two vertical rods 121 arranged in parallel. 122: The first side plate part 2, which is arranged along the edge of the first bottom plate 1 and is located above the first bottom plate 1, the first side plate part 2 includes two opposite first side plates 21 and two opposite first side plates 21 The two side panels 22, the two first side panels 21 and the two second side panels 22 are all plastic side panels, the two first side panels 21 and the two second side panels 22 are enclosed to form a rectangular...

Embodiment 2

[0030] see Figure 1 to Figure 4 , the figure shows a trolley with plastic side panels provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the second sleeve The end face of the unit 222 is in contact with the end face of the first sleeve 211; the end face of the second sleeve unit 222 has a first arc 224, and the end face of the first sleeve 211 has a second arc 213 splicing the first arc 224; Through the docking of the first arc surface and the second arc surface, the connection between the adjacent two side plates is more stable, and the mutual interference between the connected sleeves is prevented. At the same time, a There are two matching serrated surfaces, so that after splicing, the two arc surfaces can prevent the fracture problem of the sleeve caused by the impact force of the side plate, so that the strength here can be higher.

Embodiment 3

[0032] see Figure 1 to Figure 4 , the figure shows a trolley with plastic side panels provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first side panel The surface of 21 is provided with a first Z-shaped rib 214 . Through the setting of the above-mentioned structure, the strength of the first side plate can be made higher, and the effect of the Z-shaped rib can be used to guide the impact force from the outside to the sleeve, and cooperate with the above-mentioned arc surface and serrated surface. So that the side plate can obtain higher strength guarantee.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com