A temperature-controlled swimming type swirl gas well drainage plunger

A swimming, drainage column technology, applied in the production of fluids, wellbore/well components, machines/engines, etc., to achieve a large contribution rate, avoid premature flooding and stop production, and achieve significant technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

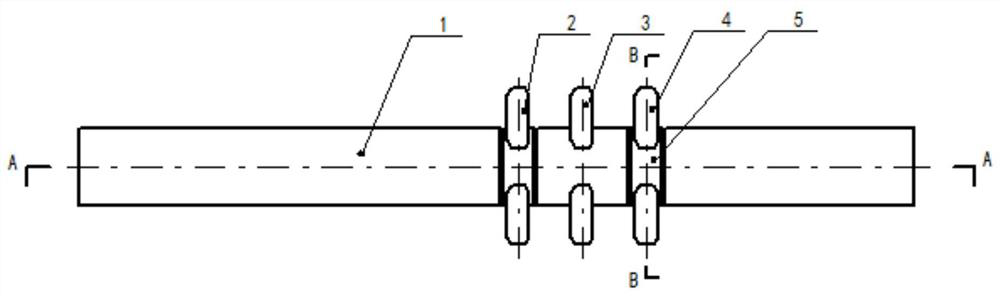

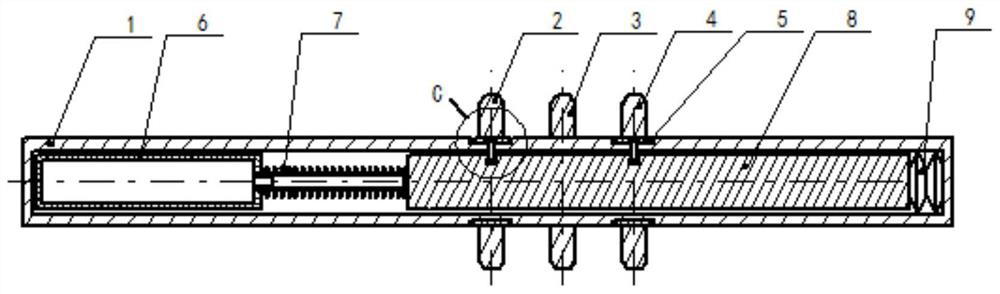

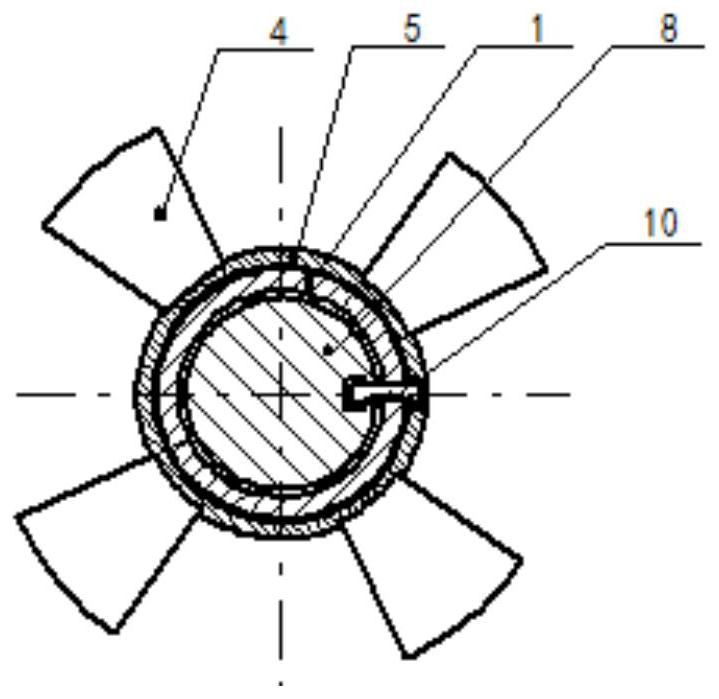

[0022] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings; the following embodiments are illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following embodiments.

[0023] A temperature-controlled swimming type swirl gas well drainage plunger, including an outer cylinder 1, a liquid storage cylinder 6, a telescopic bellows 7, and a control rod 8. A control rod is installed in a coaxial gap on one side of the outer cylinder, and the control rod is connected to the A disc spring 9 is coaxially installed between the outer cylinders; a liquid storage cylinder is fixed on the other side of the outer cylinder, and a telescopic bellows is coaxially installed between the liquid storage cylinder and the control rod; A fixed vane 3 is installed coaxially and radially at the position of the control rod. An upper vane 2 and a lower vane 4 are respectively coaxially ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com