A waterproof touch socket

A socket and contact base technology, applied in the direction of preventing contact with live contacts, base/housing, coupling device, etc., can solve problems such as inability to be truly effectively waterproof, unable to quickly cooperate and use, and save costs and processes, and facilitate maintenance. and replacement parts, the effect of light and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

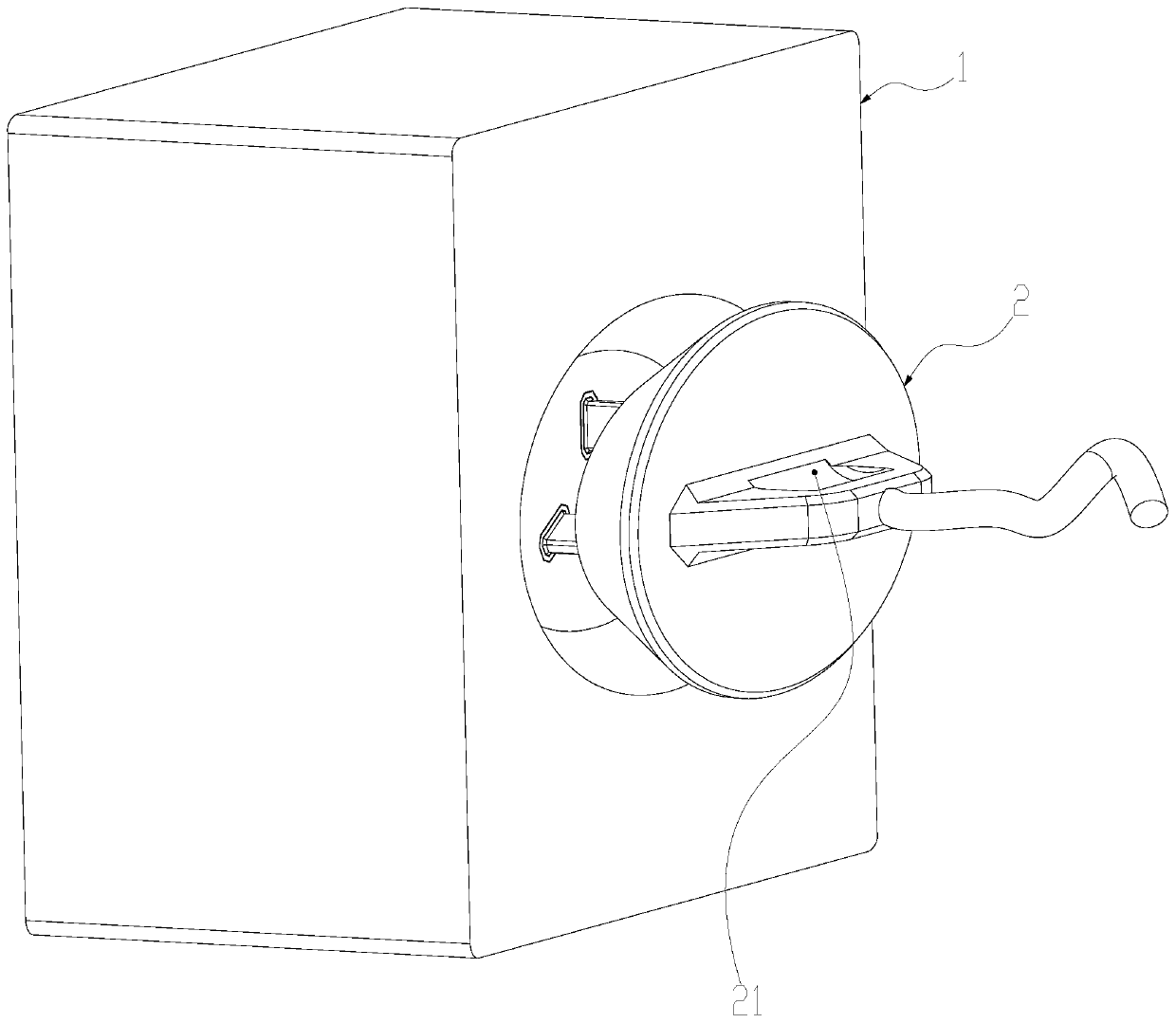

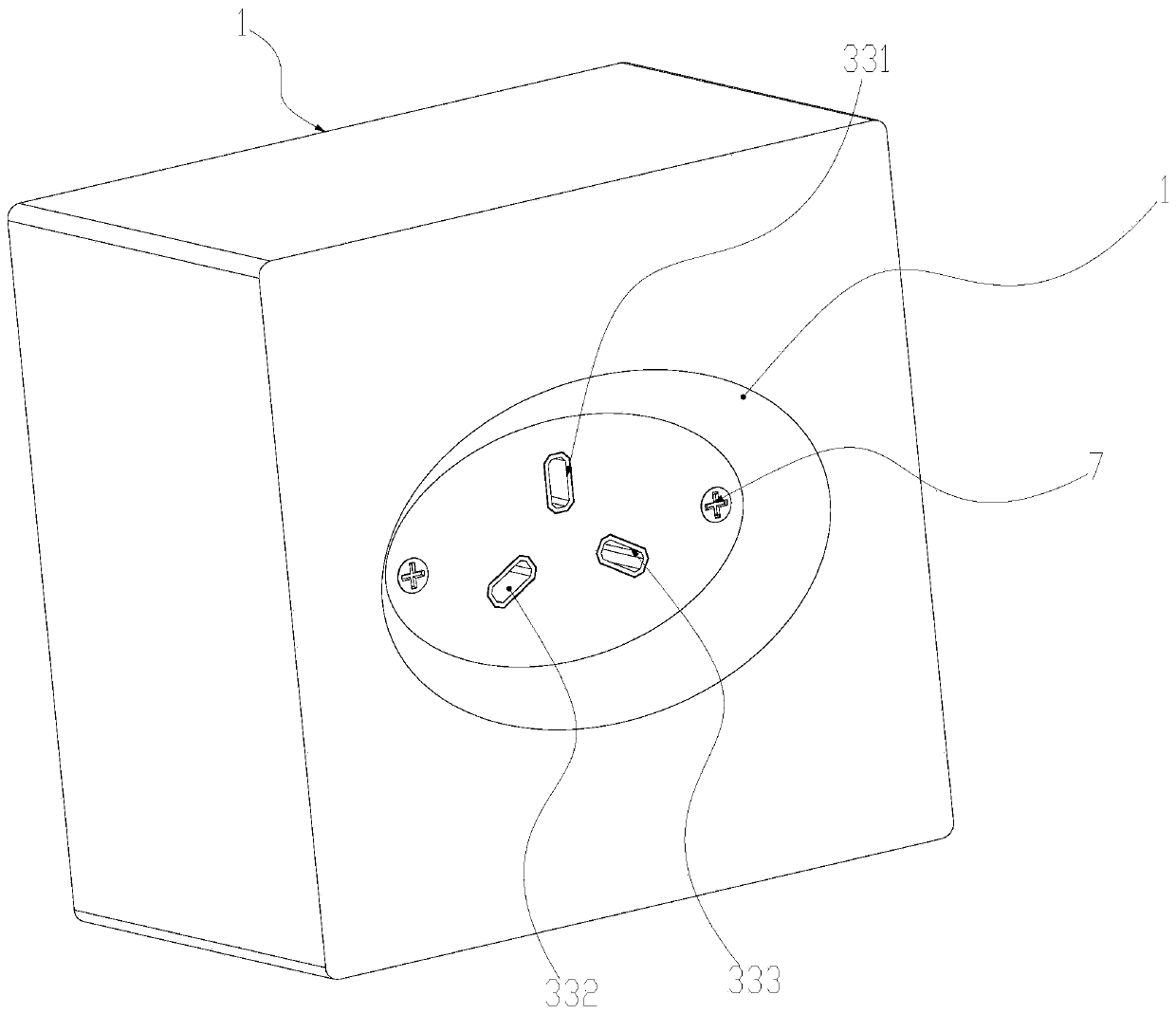

[0059] Such as Figures 1 to 13 The shown waterproof touch socket includes a plug body 3 , a plug 2 and an installation shell 1 . The above-mentioned insert body 2 is fixed in the installation shell 1,

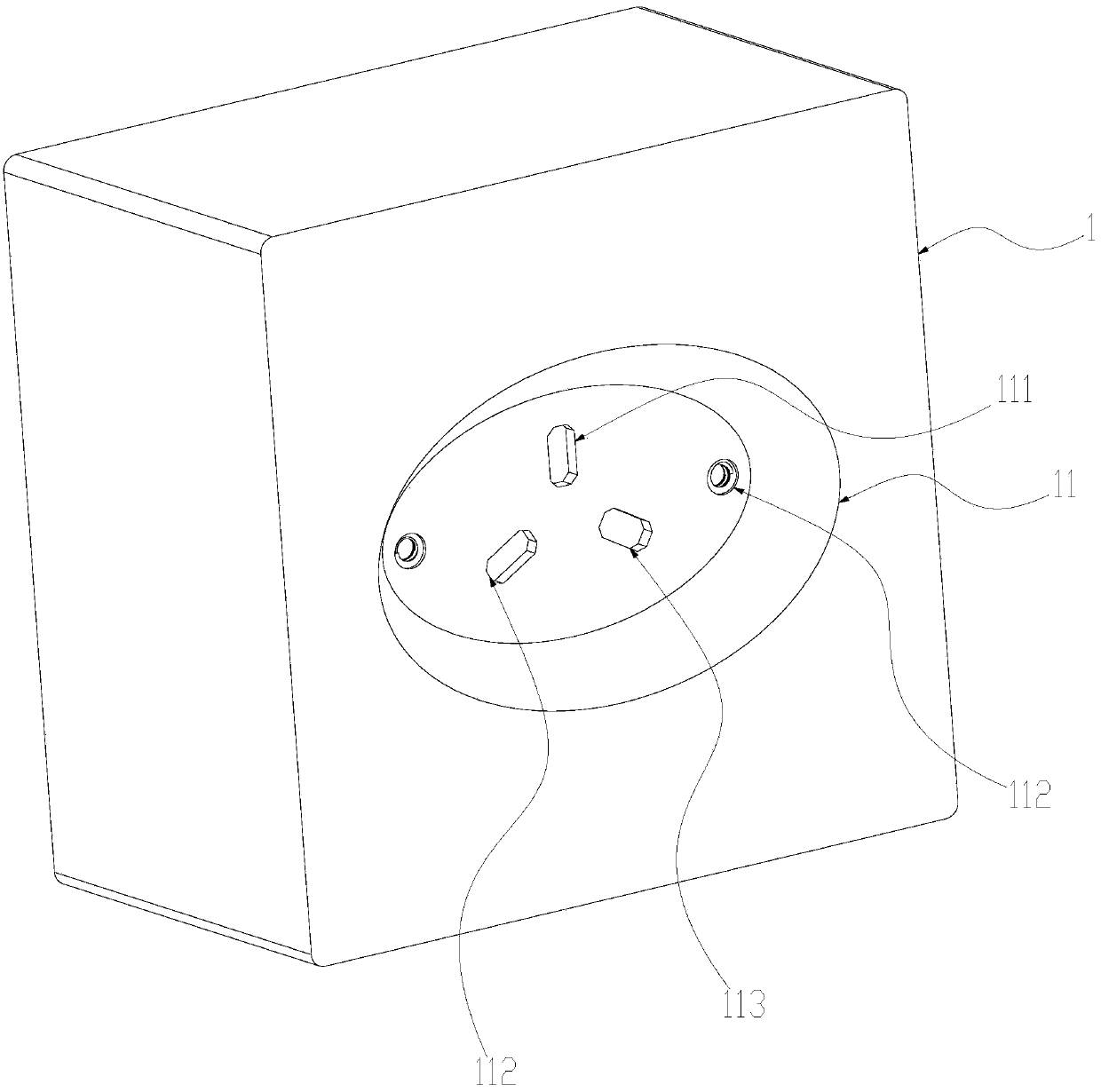

[0060] An installation slot 11 is provided on the outer side of the installation shell 1 , and an installation hole 111 for a ground wire, an installation hole 112 for a live wire, and an installation hole 113 for a neutral wire are respectively provided in the installation slot 11 .

[0061] The plug 2 is composed of a handle 21 , a ground contact 25 , a live contact 24 and a neutral contact 24 . The ground wire contact 25 , the live wire contact 24 , and the neutral wire contact 24 are all surrounded by an insulating layer 26 .

[0062] Above-mentioned insulation layer 26 leans on the bare part end of ground wire contact head 25, live wire contact head 24, zero line contact head 24, is provided with annular flange, and above-mentioned annular flange and live wire contact g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com